(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 6:30 24/11/2024 to 4:30 (IST) 25/11/2024. We apologize for the inconvenience.

- Please note that the MISUMI Pune office and warehouse will be closed on November 20th due to the state election.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

Hinges(Cleaning Method:Degreasing)

Take advantage of the convenience of free shipping and no minimum order when purchasing of hinges. If you have any doubts or require assistance in choosing the right product, our experts are readily available to provide.

Search by specifying the lower class category

Flat Hinges

Flat Hinges Detachable Hinges

Detachable Hinges Concealed Hinges

Concealed Hinges Damper Hinges, Spring Hinges

Damper Hinges, Spring Hinges Other Hinges and Nuts for Hinge

Other Hinges and Nuts for Hinge

Brand |

|

|---|---|

| CAD |

|

| Days to Ship |

|

2 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

![[Clean & Pack]Nuts for Pull Handles](//content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/v1/p/jp/product/series/110310832049/110310832049_001_20230911105917.jpg?$product_view_b$)

[Clean & Pack]Nuts for Pull Handles

MISUMI

Three types of cleaning methods are available: degreasing, precision cleaning, and electrolytic polishing + precision cleaning. They can be ordered from one piece with the standard part number.

This eliminates the need for customer cleaning or outsourced cleaning, reducing the amount of time and effort required.■Part Number for Clean & Pack Products·Degreasing (Anti-rust single packing) : Part Number SL-□□ ·Precision cleaning (Degassing double packing) : Part Number SH-□□ ·Electrolytic polishing + precision cleaning (Degassing double packing) : Part Number SHD-□□ Product Part Number Cleaning Method Packaging Type Effects Compared to Uncleaned Product Environment (Standard) Process SL-□□ Degreasing Anti-rust packing Oil removal General environment Regular assembly process Post battery assembly process SH-□□ Precision cleaning Degassing double packing Oil removal

Dust removalClean environment (Class 10 to -1,000) Battery assembly process LCD-related post assembly process In-vehicle camera assembly process SHD-□□ Electrolytic polishing + precision cleaning Degassing double packing Oil removal

Dust removal

Outgas reductionVacuum environment

Clean environment (Class 10 to -1,000)Pre-semiconductor process Liquid crystal deposition process Pre-OLED process ■Notes

Cleaning also removes rust prevention oil, which may make the product more susceptible to rusting than an uncleaned product.

Please be careful about the application location and storage environment.

A nut for pull handles. [Body Material] [Stainless Steel]SUS304- Volume Discount

Length L(mm) Flat Hinge Type Width W(mm) Body Material Main Body Type Operating Environment Mounting Method Additional Function Mounting Screw Hole Type Detachable, Flag Hinge Type Main Body Surface Treatment Reversed Cleaning Method Characteristics/Applications Material Details Environmentally friendly - - - - Related Components - - - - - - - Degreasing Clean Washed ~ Heat Resistance SUS304 RoHS Compliant (10 Substances) From: ₹ 743.35 Days to Ship: 10 Day(s) or more  10 Day(s) or more

10 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

![[Clean & Pack]Economy Series - Hinges, Countersink, Stainless Steel](//content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/v1/p/jp/product/series/110310832589/110310832589_001_20230911105917.jpg?$product_view_b$)

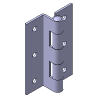

[Clean & Pack]Economy Series - Hinges, Countersink, Stainless Steel

MISUMI

Three types of cleaning methods are available: degreasing, precision cleaning, and electrolytic polishing + precision cleaning. They can be ordered from one piece with the standard part number.

This eliminates the need for customer cleaning or outsourced cleaning, reducing the amount of time and effort required.■Part Number for Clean & Pack Products·Degreasing (Anti-rust single packing) : Part Number SL-□□ ·Precision cleaning (Degassing double packing) : Part Number SH-□□ ·Electrolytic polishing + precision cleaning (Degassing double packing) : Part Number SHD-□□ Product Part Number Cleaning Method Packaging Type Effects Compared to Uncleaned Product Environment (Standard) Process SL-□□ Degreasing Anti-rust packing Oil removal General environment Regular assembly process Post battery assembly process SH-□□ Precision cleaning Degassing double packing Oil removal

Dust removalClean environment (Class 10 to -1,000) Battery assembly process LCD-related post assembly process In-vehicle camera assembly process SHD-□□ Electrolytic polishing + precision cleaning Degassing double packing Oil removal

Dust removal

Outgas reductionVacuum environment

Clean environment (Class 10 to -1,000)Pre-semiconductor process Liquid crystal deposition process Pre-OLED process ■Notes

Cleaning also removes rust prevention oil, which may make the product more susceptible to rusting than an uncleaned product.

Please be careful about the application location and storage environment.

[Bulk Purchase Deals] * A minimum order quantity (from 20 pcs.) is set. The minimum order quantity may differ depending on the type and size. Please check the Part Number tab or WOS.

Countersink processing for a wide range of applications, elegant appearance, and excellent durability

MISUMI Low Price New Brand [Economy Series] Sequentially expanding our product lineups. See here for special pages. Product LineupLength L(mm) Flat Hinge Type Width W(mm) Body Material Main Body Type Operating Environment Mounting Method Additional Function Mounting Screw Hole Type Detachable, Flag Hinge Type Main Body Surface Treatment Reversed Cleaning Method Characteristics/Applications Material Details Environmentally friendly 66 - 36 - Flat Hinges Standard Screw Mounting Not Provided Countersunk Holes - - For Both Right and Left Sides Degreasing Clean Washed ~ Heat Resistance SUS304 Not RoHS Compliant From: ₹ 664.04 Days to Ship: 10 Day(s) or more  10 Day(s) or more

10 Day(s) or more

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Length L(mm) |

| Flat Hinge Type |

| Width W(mm) |

| Body Material |

| Main Body Type |

| Operating Environment |

| Mounting Method |

| Additional Function |

| Mounting Screw Hole Type |

| Detachable, Flag Hinge Type |

| Main Body Surface Treatment |

| Reversed |

| Cleaning Method |

| Characteristics/Applications |

| Material Details |

| Environmentally friendly |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| Brand | MISUMI | MISUMI |

| Product Series | [Clean & Pack]Economy Series - Hinges, Countersink, Stainless Steel | |

| CAD |

| |

| From | ₹ 743.35 | ₹ 664.04 |

| Days to Ship | 10 Day(s) or more | 10 Day(s) or more |

| Length L(mm) | - | 66 |

| Flat Hinge Type | - | - |

| Width W(mm) | - | 36 |

| Body Material | - | - |

| Main Body Type | Related Components | Flat Hinges |

| Operating Environment | - | Standard |

| Mounting Method | - | Screw Mounting |

| Additional Function | - | Not Provided |

| Mounting Screw Hole Type | - | Countersunk Holes |

| Detachable, Flag Hinge Type | - | - |

| Main Body Surface Treatment | - | - |

| Reversed | - | For Both Right and Left Sides |

| Cleaning Method | Degreasing | Degreasing |

| Characteristics/Applications | Clean Washed ~ Heat Resistance | Clean Washed ~ Heat Resistance |

| Material Details | SUS304 | SUS304 |

| Environmentally friendly | RoHS Compliant (10 Substances) | Not RoHS Compliant |

Loading...

Configure

Specification/Dimensions

-

Length L(mm)

- 2,000

- 6

- 6.5

- 17

- 19

- 20

- 22

- 23.5

- 24

- 25

- 25.5

- 26

- 27.5

- 29

- 30

- 31

- 31.5

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 40

- 40.5

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 50

- 50.5

- 51

- 52

- 54

- 54.5

- 55

- 56

- 57

- 59

- 60

- 61

- 62

- 63

- 63.4

- 63.5

- 64

- 65

- 66

- 67

- 68

- 70

- 71

- 71.7

- 72

- 73

- 75

- 75.5

- 76

- 76.5

- 76.7

- 77

- 78

- 79

- 80

- 81

- 81.7

- 82

- 83

- 84

- 85

- 86

- 86.7

- 87

- 87.5

- 88

- 89

- 90

- 92

- 94

- 95

- 95.3

- 96

- 100

- 101

- 101.2

- 101.5

- 101.7

- 102

- 103

- 104

- 106

- 107

- 108

- 109

- 110

- 113

- 114

- 114.5

- 115

- 117.5

- 118

- 120

- 121

- 123

- 124

- 125

- 126

- 126.5

- 127

- 130

- 132

- 132.5

- 138

- 139

- 139.7

- 140

- 144

- 145

- 148

- 149

- 150

- 151

- 152

- 152.5

- 153

- 154

- 155

- 158

- 160

- 161

- 161.5

- 162

- 170

- 183

- 184

- 186

- 186.4

- 190

- 200

- 201

- 204

- 210

- 222.3

- 224

- 225

- 250

- 258

- 264

- 289.3

- 300

- 340

- 350

- 400

- 442

- 450

- 476

- 576

- 600

- 626

- 750

- 850

- 900

- 1000

- 1200

- 1800

- 1829

- 1872

- 2000

- 2133

- 2400

- 2500

-

Flat Hinge Type

-

Width W(mm)

-

Body Material

- Stainless Steel

- Steel

- Brass

- Aluminum

- Zinc Alloy

- Resin

-

Main Body Type

-

Operating Environment

- Standard

- Corrosion Resistance

- Abrasion Resistance

- Cleanroom

-

Mounting Method

-

Additional Function

-

Mounting Screw Hole Type

-

Detachable, Flag Hinge Type

-

Main Body Surface Treatment

-

Reversed

-

Cleaning Method

- Degreasing

- Precision Cleaning

- Electrolytic Polishing + Precision Cleaning

-

Characteristics/Applications

-

Material Details

-

Environmentally friendly

- RoHS Compliant (10 Substances)

- Not RoHS Compliant

Related Categories to Hinges

-

- Catches

- Door Stays

- Telescopic Slide Rails

- Fasteners, Draw Latches

- Latch Handles, Locks, Keys

- Lighting System

- Gas Springs

- Wires, Chains, Metal Fittings, Small Work Pieces

- Parts, Small Work Pieces

- Hanging Tools

- Extrusion Kits and Mesh Fences

- Handle

- Knob Screws

- Lever

- Rotation Handles, Crank Handles

- Hanger Hooks

- Shelves, Shelf Supports, Shelf Poles

- Door Wheels

- Handles

- Hinges

- DIY Supplies

FAQ about Hinges

- Question: What is the opening/closing angle of hinge?

- Answer: Opening angle is 180° where the hinge plates are aligned in horizontally,

Closing angle is 0° where the front surfaces of each plate overlapping. - Question: What is the meaning of Left-hand and Right-hand hinge?

- Answer: Left-hand hinge is a mechanism that hinge fixed at the left-hand side and can be opened or closed at the right-hand side when facing the door.

Right-hand hinge is a mechanism that hinge fixed at the right-hand side and can be opened or closed at the left-hand side when facing the door.

Please select product according to their function. - Question: When using in horizontal direction, is there any change in the allowable load?

- Answer: No change.

- Question: What materials are commonly used for hinges?

- Answer: Common materials used for hinges include:

1. Steel: Known for its strength, durability, and affordability, steel hinges are widely used across various applications.

2. Stainless Steel: Highly resistant to corrosion and staining, stainless steel hinges are commonly used in outdoor or high-humidity settings, as well as in medical or food processing equipment.

3. Aluminum: Lightweight and corrosion-resistant, aluminum hinges are favored for outdoor applications or where weight is a concern, such as on aluminum doors or cabinets.

4. Zinc: Zinc hinges provide a cost-effective option with decent corrosion resistance, often serving as an alternative to brass or steel hinges. - Question: How do I choose the right hinge for my needs?

- Answer: To choose the right hinge for your needs, consider the following factors:

1. Environment: Choose a hinge suitable for the environment it will be placed in, such as indoor or outdoor use

2. Type: Select the appropriate hinge type based on your application, such as Continuous Hinges, Butt hinge, Concealed Hinges and so on

3. Size: Ensure the hinge is of the correct size for the objects you want to connect, considering width, height, and length

4. Strength: Choose a hinge with sufficient strength to support the weight of the objects it will connect

5. Finish: Select a hinge finish that matches the appearance of your cabinets or doors, or choose a bold finish to draw attention

6. Material: Choose a hinge material that is suitable for your environment and application, such as stainless steel for outdoor use or brass for decorative purposes

7. Fastener holes: Consider the number of fastener holes and their location when choosing a hinge - Question: Are there any hinges suitable for heavy loads or special environments?

- Answer: Yes, there are hinges suitable for heavy loads or special environments. Heavy-duty hinges are designed to withstand substantial loads and frequent use, making them ideal for industrial and commercial. These hinges are available in various types, including continuous hinges, concealed hinges, and Torque Hinges. They are typically made from robust materials such as steel and stainless steel, often featuring protective coatings or materials that make them suitable for outdoor or harsh environments.

- Question: How do I install different types of hinges?

- Answer: Installing different types of hinges can vary depending on the type of hinge and the application. However, there are some general steps that can be followed.

1. Determine the type of hinge needed for the application. Common types of hinges include Continuous Hinges, Butt hinge,Concealed Hinges

2. Determine the placement of the hinge on the door or cabinet.

3. Drill holes for the screws using a Vix bit or a specialty bit that drills holes centered on a hinge's mounting holes.

4. Insert screws into the holes and tighten them.

5. Test the hinge to ensure it is properly installed and functioning correctly. - Question: What should I consider for hinge maintenance?

- Answer: To maintain hinges effectively, consider the following guidelines:

1. Lubrication: Apply light oil or silicone spray to non-self-lubricating hinges to prolong their lifespan.

2. Cleaning: Wipe off excess oil to prevent dirt buildup on hinges.

3. Tighten Screws: Regularly check and tighten loose screws, adding more if necessary for added support.

4. Check Alignment: Ensure hinges are aligned correctly and doors/gates are not sagging or misaligned.

5. Protection: Use weather-resistant materials for outdoor hinges to prevent rust and corrosion.

6. Regular Inspections: Periodically inspect hinges for signs of wear, damage, or misalignment.

7. Replace Worn Parts: Replace any worn or damaged components to maintain functionality and durability.

![[Clean & Pack]Nuts for Pull Handles](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/v1/p/jp/product/series/110310832049/110310832049_001_20230911105917.jpg?$product_view_b$)

![[Clean & Pack]Economy Series - Hinges, Countersink, Stainless Steel](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/v1/p/jp/product/series/110310832589/110310832589_001_20230911105917.jpg?$product_view_b$)

![[Clean & Pack]Nuts for Pull Handles](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_c/v1/p/jp/product/series/110310832049/110310832049_001_20230911105917.jpg?$product_view_c$)

![[Clean & Pack]Economy Series - Hinges, Countersink, Stainless Steel](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_c/v1/p/jp/product/series/110310832589/110310832589_001_20230911105917.jpg?$product_view_c$)

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy