(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

Chamfering / Centering Tools(Tip angle (θ):145+90)

Search by specifying the lower class category

Centering/Countersink

Centering/Countersink Chamfer, V-Grooves

Chamfer, V-Grooves Inner R

Inner R Replaceable Blade Type Chamfering Tools/Tips/Blades

Replaceable Blade Type Chamfering Tools/Tips/Blades

Brand |

|

|---|---|

| CAD |

|

| Days to Ship |

|

1 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

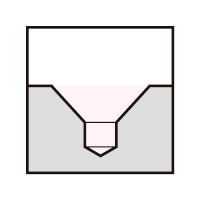

Chamfering Cutter NC Spot Drill (Chip)

Nine9

[Features]

·Insert for NC spot drill holder.

·Momitsuke and chamfering are integrated into one process.

·The tip angle of 145° prevents drill shoulder chipping.

[Applications]

·For CNC lathes, CNC compound lathes, and machining centers for drilling pilot holes for tapping

·Applying kneading only at 145°

·Chamfering, V-grooving.Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) - - 145+90 - - - - Available TiAlN - From: ₹ 4,972.18 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

| Brand |

|---|

| Product Series |

| From |

| Days to Ship |

| Tool Material Type |

| Tool Diameter (D)(mm) |

| Tip angle (θ) |

| Application |

| work material |

| Single blade, two blades |

| Peripheral Blade Y/N |

| Coating Y/N |

| Coating Type |

| R Size (R)(mm) |

You can add up to 6 items per a category to the compare list. | |

| Brand | Nine9 |

| Product Series | |

| From | ₹ 4,972.18 |

| Days to Ship | 6 Day(s) or more |

| Tool Material Type | - |

| Tool Diameter (D)(mm) | - |

| Tip angle (θ) | 145+90 |

| Application | - |

| work material | - |

| Single blade, two blades | - |

| Peripheral Blade Y/N | - |

| Coating Y/N | Available |

| Coating Type | TiAlN |

| R Size (R)(mm) | - |

Loading...

Configure

Specification/Dimensions

-

Tool Material Type

-

Tool Diameter (D)(mm)

- 0 to 2

- 0.02

- 0.03

- 0.04

- 0.05

- 0.06

- 0.07

- 0.08

- 0.09

- 0.1

- 0.11

- 0.12

- 0.13

- 0.14

- 0.15

- 0.16

- 0.17

- 0.18

- 0.19

- 0.2

- 0.21

- 0.22

- 0.23

- 0.24

- 0.25

- 0.26

- 0.27

- 0.28

- 0.29

- 0.3

- 0.3, 0.6

- 0.35

- 0.4

- 0.45

- 0.45~2.1

- 0.45~2.7

- 0.5

- 0.5, 1

- 0.55

- 0.6

- 0.65

- 0.65~2.1

- 0.65~2.7

- 0.7

- 0.75

- 0.8

- 0.85

- 0.9

- 0.95

- 1

- 1, 2

- 1–6

- 1/8

- 1/16

- 1/32

- 1/64

- 1.1

- 1.2

- 1.25

- 1.3

- 1.4

- 1.5

- 1.6

- 1.7

- 1.8

- 1.9

- 2.

- 2

- 2–10

- 2~13

- 2.1

- 2.2

- 2.3

- 2.4

- 2.5

- 2.6

- 2.7

- 2.8

- 2.9

- 3

- 3~14

- 3 to 15

- 3/16

- 3/32

- 3/64

- 3.1

- 3.15

- 3.2

- 3.3

- 3.4

- 3.5

- 3.6

- 3.8

- 4

- 4.2

- 4.3

- 4.4

- 4.5

- 4.6

- 4.8

- 5

- 5/16

- 5/32

- 5/64

- 5.1

- 5.2

- 5.3

- 5.4

- 5.5

- 5.6

- 5.8

- 6

- 6.2

- 6.3

- 6.3,8.3,10.4,12.4,16.5,20.5

- 6.30/8.30/10.40/12.40/16.50/20.50

- 6.3/8.3/10.4/12.4/16.5/20.5

- 6.35

- 6.4

- 6.5

- 6.6

- 6.8

- 7

- 7.2

- 7.3

- 7.4

- 7.5

- 7.6

- 7.7

- 7.8

- 8

- 8.2

- 8.3

- 8.4

- 8.5

- 8.8

- 9

- 9.1

- 9.4

- 9.5

- 9.52

- 10

- 10.1

- 10.2

- 10.3

- 10.4

- 10.5

- 10.8

- 11

- 11.1

- 11.2

- 11.4

- 11.5

- 11.88

- 12

- 12.1

- 12.3

- 12.4

- 12.5

- 12.7

- 13

- 13.4

- 13.5

- 14

- 14.2

- 14.4

- 14.5

- 14.6

- 14.8

- 15

- 15.1

- 15.2

- 15.4

- 15.5

- 15.6

- 15.87

- 16

- 16.15

- 16.3

- 16.5

- 17

- 17.1

- 17.7

- 18

- 18.2

- 18.5

- 18.6

- 19

- 19.05

- 19.5

- 20

- 20.5

- 21

- 21.77

- 22

- 22.3

- 22.5

- 23

- 23.4

- 23.5

- 24

- 24.5

- 25

- 25.0(+0.3)

- Max: 25, Min: 4.2

- 25.20

- 25.3

- 26

- 26.5

- 26.6

- 27

- 27.5

- 28

- 28.5

- 29

- 29.9

- 30

- Max: 30, Min: 4

- 30.20

- 30.5

- 31

- Max: 31, Min: 10

- 31.5

- 31.7

- 31.9

- 32

- 32.6

- 32.7

- 33.1

- 33.3

- 34

- 34.1

- 34.8

- 34.9

- 35

- 35.4

- 35.9

- 36

- 36.9

- 37

- 37.1

- 37.9

- 38

- 39

- 39.83

- 40

- Max: 41, Min: 20

- 42

- 43

- 45

- 45.6

- 46

- 47

- 48

- 49

- 49.85~134.6

- 50

- 50.7

- 51

- 52

- 52.8

- 53

- 53.6

- 53.91

- 54

- 54.3

- 55

- 56

- 56.8

- 57.0

- 57.9

- 58

- 58.2

- 60

- 61.4

- 62

- 62.2

- 63

- 64

- 64.6

- 65

- 66

- 67.4

- 67.94

- 69.2

- 69.8

- 70

- 71.8

- 72

- 73.3

- 74

- 75

- 76

- 80

- 90

- 95

- 100

-

Tip angle (θ)

-

Application

-

work material

-

Single blade, two blades

-

Peripheral Blade Y/N

-

Coating Y/N

-

Coating Type

-

R Size (R)(mm)

- 0.1

- 0.15

- 0.2

- 0.25

- 0.3

- 0.35

- 0.4

- 0.45

- 0.5

- R0.5

- 0.5/1/1.5/2

- 0.5 to 4

- 0.5~5

- 0.55

- 0.6

- 0.65

- 0.7

- 0.75

- R0.75

- 0.8

- 0.85

- 0.9

- 0.95

- 1

- 1RM

- 1RY

- R1

- 1, 1.5

- 1/2/3/4

- 1–3

- 1–5

- 1.05

- 1.1

- 1.15

- 1.2

- 1.25

- R1.25

- 1.3

- 1.35

- 1.4

- 1.45

- 1.5

- R1.5

- 1.55

- 1.6

- 1.65

- 1.7

- 1.75

- 1.8

- 1.85

- 1.9

- 1.95

- 2

- 2RM

- 2RY

- R2

- 2, 3

- 2.05

- 2.1

- 2.15

- 2.2

- 2.25

- 2.3

- 2.35

- 2.4

- 2.45

- 2.5

- R2.5

- 2.6

- 2.7

- 2.75

- 2.8

- 2.9

- 3

- 3RM

- 3RY

- R3

- 3.25

- 3.5

- R3.5

- 3.75

- 4

- 4RM

- 4RY

- R4

- 4.25

- 4.5

- R4.5

- 4.75

- 5

- 5RM

- R5

- 5–10

- 5.25

- 5.5

- 5.75

- 6

- R6

- 6.25

- 6.5

- 6.75

- 7

- R7

- 7.25

- 7.5

- 7.75

- 8

- R8

- 8.25

- 8.5

- 8.75

- 9

- R9

- 9.5

- 10

- R10

- 10.5

- 11

- 11.5

- 12

- R12

- 12.5

- R12.5

- 13

- 13.5

- 14

- 14.5

- 15

- R15

- 15.5

- 16

- R16

- 16.5

- 17

- 17.5

- 18

- 18.5

- 19

- 19.5

- 20

- 20.5

- 21

- 21.5

- 22

- 22.5

- 23

- 23.5

- 24

- 24.5

- 25

- 25.5

- 26

- 26.5

- 27

- 27.5

- 28

- 28.5

- 29

- 29.5

- 30

- XRM

- XRY

Related Categories to Chamfering / Centering Tools

-

- Carbide End Mills

- HSS End Mills

- Milling Cutter Inserts/Holders

- Customized Straight Blade End Mills

- Dedicated Cutters

- Turning Tools

- Drill Bits

- Screw-Hole-Related Tools

- Reamers

- Chamfering / Centering Tools

- Fixtures Related to Cutting Tools

- Step Drills

- Hole Saws

- Clean Key Cutters

- Core Drills (Tip Tools)

- Magnetic Drilling Machine Cutters

- Drill Bits for Electric Drilling Machines

- Woodworking Drill Cutters

- Drills for Concrete

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy