Cable Carrier Selection and Installation:

Technical Guidelines for Uptime

Publish Date: 16 Oct 2025

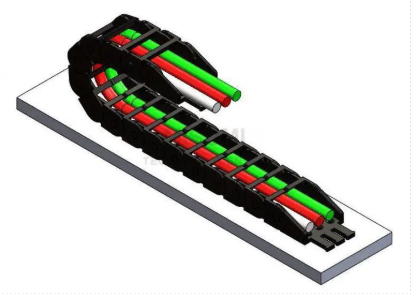

In today's automated factories, motion is constant, and precision is paramount. But what protects the lifelines of your machinery—the essential power, control, and data cables—from the constant stress of bending, rubbing, and tangling? The answer is the often-underappreciated workhorse: the Cable Carrier, sometimes colloquially called a "snake rail."

At MISUMI India, we understand that a reliable automation system starts with superior cable management. Cable carriers ensure longevity and prevent catastrophic downtime. Let's delve into what makes these devices crucial and how to utilize them for maximum factory efficiency.

What Exactly is a Cable Carrier?

A Cable Carrier is a robust mechanical device, typically made of plastic or steel, designed to house and guide various cables and hoses (power, control, pneumatic, hydraulic) in motion applications.

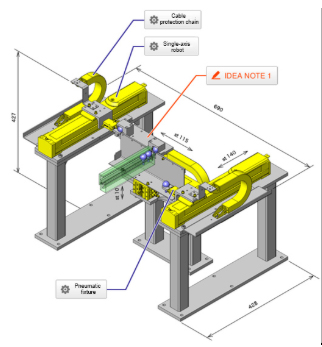

Let’s take an example of a dual single-axis robot system, commonly found in pick-and-place, assembly, or dispensing applications.

When attached to moving parts of a machine (like robot arms or CNC axes), the carrier protects the contents from:

- Bending and Flexing Stress: It limits the minimum bend radius, ensuring cables are not stressed beyond their engineered limits.

- Abrasion and Rubbing: It prevents cables from tangling or wearing against machine parts or each other.

- Contamination: Closed carriers protect wires from dust, debris, and foreign objects.

Whether you choose a standard open plastic carrier, a fully closed tube type for harsh environments, or a heavy-duty stainless steel model, the function remains the same: to ensure the safe, reliable movement of energy and data.

Example Use of Cable Carriers in Automation Systems

To truly appreciate the vital role of cable carrier chains, it's helpful to see them in action within an actual automation setup.

Selecting the Right Cable Carrier: Key Factors

Choosing the correct cable carrier is an investment in your machine's uptime. Here are the critical factors to consider:

- Strength and Durability: The carrier must be constructed from materials suitable for the operating environment (e.g., heat, chemicals, heavy loads).

- Low Noise Operation:Excessive noise during movement can signal friction or poor design. Opt for carriers with low noise and low particle generation.

- Environmental Protection:In dusty environments or where falling debris is a risk, a carrier with a solid, closed cover is essential to prevent foreign objects from damaging the contents.

- Ease of Maintenance:Look for carriers with joints that can be easily opened from the top or bottom—this simplifies installation, inspection, and replacement of internal cables.

- Installation Simplicity: The carrier system should be straightforward to mount, minimizing setup time and potential cable carrier assembly errors.

4 Essential Rules for Cable Installation within the Carrier

Properly installing cables inside the carrier is just as important as selecting the right carrier itself. Following these precautions prevents heat generation, wear, and premature failure.

1. Maintain Appropriate Separation Distance

Cables and hoses generate heat and can experience friction, so they must not be tightly packed. The required distance between items varies by type:

| Line Type | Minimum Distance Between Lines | Rationale |

|---|---|---|

| Electrical Cables | 10% of Cable Outer Diameter (OD) | Provides cooling and reduces electromagnetic interference. |

| Pneumatic Lines | 15% of Line OD | Accommodates the slight expansion and movement of air lines. |

| Hydraulic Hoses | 20% of Hose OD | Accounts for significant expansion and pressure movement, requiring the largest clearance. |

A minimum clearance of 1 mm (electrical), 2 mm (pneumatic), or 3 mm (hydraulic) between lines is recommended, even after calculating the percentage clearance.

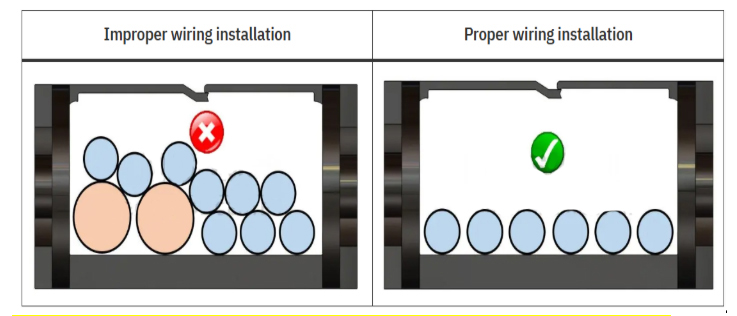

2. Avoid Overlapping and Layering Cables

Never overlap signal or power cables within the carrier. Layered cables will rub against each other during motion, generating friction and heat, which significantly accelerates cable wear and insulation breakdown. Always ensure a single layer of cables across the carrier's width.

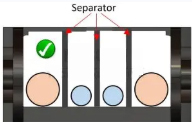

3. Ensure Even Weight Distribution

Uneven weight distribution shortens the cable carrier's service life and causes inconsistent machine motion.

| Distribution Pattern | Assessment | Solution |

|---|---|---|

Uneven Load (e.g., all heavy cables on one side) |

Improper. Causes the carrier to tilt, increasing wear and reducing rigidity. | Distribute heavier and lighter cables evenly across the width. |

Even Load, Mixed Sizes (e.g., large cables resting on small cables) |

Not Suitable. Large cables can still compress smaller ones during movement. | Use separators (dividers) to compartmentalize cables and prevent contact. |

Optimal Load with Separators |

Proper. Weight is balanced, and separators ensure all cables move independently without overlapping or pressing on others. | Achieve balance using internal dividers and grouping similar lines together. |

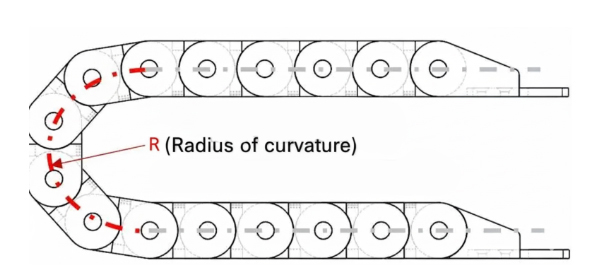

4. Respect the Carrier's Radius of Curvature (R)

The Radius of Curvature (R) of the cable carrier chain must always be larger than the minimum allowable bending radius of the most sensitive cable or hose installed inside.

- If the carrier's bend radius is too small, it will force the cables inside to bend more sharply than they can tolerate.

- This causes internal compression and strain on the conductors, leading to rapid degradation and failure.

Elevate Your Cable Management with MISUMI

Understanding the nuances of cable carrier selection and installation is key to minimizing downtime and maximizing the performance of your automation equipment. At MISUMI India, we offer a vast selection of cable carriers, separators, and accessories—from standard plastic to specialized closed and stainless steel designs—all designed for reliable, long-lasting performance.

Ready to secure your factory's lifelines?

Browse the MISUMI India catalog today to find the perfect cable carrier solution and supporting components engineered for your specific application requirements!