(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 6:30 28/7/2024 to 4:30 (IST) 29/7/2024. We apologize for the inconvenience.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

MISUMI Centering/Countersink

Brand |

|

|---|---|

| CAD |

|

| Days to Ship |

|

23 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

High-Speed Steel Center Drill, Regular / New JIS, Model A

MISUMI

[Features]

·Necessary items for positioning processing

·Non-coated high-speed steel double-edged 2-flute tip angle 120° type (New JIS A type)Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) High-speed steel 1 ~ 5 - Centering (Positioning) general steel[○] Double-edged NA NA - - From: ₹ 259.00 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

MISUMI

The non-coated design allows the edge of the tip to stand, achieving the high cut-off performance.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 0.3 ~ 2 - Centering (Positioning) / Hole Chamfer general steel[◎] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[◎] / Aluminum[◎] / Copper[◎] Single blade NA NA - - From: ₹ 3,648.20 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

TiAlN Coated Carbide Center Drill, 60° Chamfering Model / Regular, Long

MISUMI

Carbide center drill that's ideal for centering in mass production drilling

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 0.5 ~ 5 - Centering (Positioning) general steel[◎] / Quenched and tempered steel[○] / high hardness steel[○] / Stainless Steel[○] / Cast Iron[◎] / Aluminum[◎] / Copper[◎] Double-edged NA Available TiAlN - From: ₹ 3,078.40 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

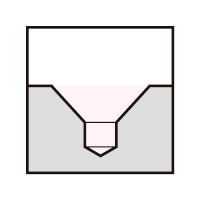

High-Speed Steel Center Drill, 90° Chamfered Blade Model

MISUMI

Frequently used standard sizes are offered at affordable prices

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) High-speed steel 1 ~ 5 - Centering (Positioning) general steel[○] Double-edged NA NA - - From: ₹ 392.20 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

TiAlN Coated Carbide Countersink, 3-Flute / 90°, Regular, Long Shack

MISUMI

A carbide countersink that's essential in chamfering and deburring

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 6.3 ~ 20.5 - Hole Chamfer general steel[◎] / Quenched and tempered steel[◎] / high hardness steel[○] / Stainless Steel[○] / Cast Iron[◎] / Aluminum[◎] / Copper[◎] Single blade NA Available TiAlN - From: ₹ 4,580.60 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

TiN Coated / Non-Coated High-Speed Steel NC Spot Drill

MISUMI

Long service life that's made possible by the coating technology. Ideal for Hole Chamfering and Centering

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Cobalt HSS 2 ~ 20 90 ~ 120 Centering (Positioning) / Hole Chamfer general steel[○/◎] / Quenched and tempered steel[○] / Stainless Steel[○] / Aluminum[○] / Copper[○] Single blade NA Available / NA TiN / Non-Coated - From: ₹ 407.00 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

TiAlN Coated High-Speed Steel Center Drill, Regular Model

MISUMI

TiAlN coated type of the popular center drill

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) High-speed steel 1 ~ 4 - Centering (Positioning) general steel[◎] / high hardness steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] Double-edged NA Available TiAlN - From: ₹ 976.00 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

TiAlN Coated Carbide NC Spot Drill, Small Diameter, Multi-Functional Model

MISUMI

A single tool with high efficiency that's capable of all centering, chamfering and V grooving

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 0.5 ~ 2 60 ~ 120 Centering (Positioning) / Hole Chamfer general steel[◎] / Quenched and tempered steel[◎] / high hardness steel[○] / Stainless Steel[○] / Cast Iron[◎] / Aluminum[◎] / Copper[◎] Single blade Available Available TiAlN - From: ₹ 2,464.20 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

TiAlN Coated Carbide NC Spot Drill, Regular / Long Shack

MISUMI

Carbide spot drill that contributes to higher efficiency in chamfering

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 2 ~ 12 90 ~ 120 Centering (Positioning) / Hole Chamfer general steel[◎] / Quenched and tempered steel[◎] / Stainless Steel[○] / Cast Iron[◎] / Aluminum[◎] / Copper[◎] Single blade NA Available TiAlN - From: ₹ 1,998.00 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

TiAlN Coated Carbide Center Drill, 90° Chamfering Model

MISUMI

Carbide center drill that's ideal for centering in mass production drilling

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Carbide 1 ~ 4 - Centering (Positioning) general steel[◎] / Quenched and tempered steel[◎] / high hardness steel[○] / Stainless Steel[○] / Cast Iron[◎] / Aluminum[◎] / Copper[◎] Double-edged NA Available TiAlN - From: ₹ 4,306.80 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

TiAlN Coated High-Speed Steel NC Spot Drill, Multi-Functional Model

MISUMI

A single tool with high efficiency that's capable of all centering, chamfering and V grooving

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Cobalt HSS 3 ~ 12 90 Centering (Positioning) / Hole Chamfer general steel[◎] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] Single blade NA Available TiAlN - From: ₹ 1,598.40 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

TiAlN Coated High-Speed Steel NC Spot Drill, Regular, Long Shack

MISUMI

TiAlN coated type of the popular spot drill

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Cobalt HSS 2 ~ 12 90 Centering (Positioning) / Hole Chamfer general steel[◎] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] Single blade NA Available TiAlN - From: ₹ 999.00 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

TiAlN Coated High-Speed Steel Center Drill, Long Model

MISUMI

The adoption of TiAlN coating with excellent wear resistance allows for the long service life and high-speed cutting.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) High-speed steel 1 ~ 4 - Centering (Positioning) general steel[◎] / high hardness steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] Double-edged NA Available TiAlN - From: ₹ 1,480.00 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

TiAlN Coated High-Speed Steel Center Drill, 90° Chamfering Model

MISUMI

The 90° type that's simultaneously capable of chamfering

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) High-speed steel 1 ~ 4 - Centering (Positioning) general steel[◎] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] Double-edged NA Available TiAlN - From: ₹ 902.80 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

TiAlN Coated High-Speed Steel Center Drill, R Model

MISUMI

R-shaped type that's ideal for precision machining

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) High-speed steel 1 ~ 4 - Centering (Positioning) general steel[◎] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] Double-edged NA Available TiAlN - From: ₹ 902.80 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

High-Speed Steel Center Drill, Long / New JIS, Model A

MISUMI

[Features]

·Necessary items for positioning processing

·Non-coated high-speed steel double-edged 2-flute tip angle 120° (New JIS A type)

·Effective for positioning processing in deep placesTool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) High-speed steel 1 ~ 5 - Centering (Positioning) general steel[○] Double-edged NA NA - - From: ₹ 1,036.00 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

TiN Coated High-Speed Steel Countersink / 3-Flute / 90°

MISUMI

Necessities in hole chamfering and deburring are available at low prices

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) High-speed steel 6.3 ~ 20.5 - Hole Chamfer general steel[◎] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] Single blade NA Available TiN - From: ₹ 1,472.87 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

TiAlN Coated High-Speed Steel Countersink, 3-Flute / 90°, Regular, Long Shack Model

MISUMI

Ideal for the hole chamfering of countersunk bolts with 90° chamfer.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Cobalt HSS 6.3 ~ 20.5 - Hole Chamfer general steel[◎] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] Single blade NA Available TiAlN - From: ₹ 1,724.20 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

TiAlN Coated High-Speed Steel Countersink, 1-Flute / 90°

MISUMI

1-flute type with high versatility in countersink

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Cobalt HSS 10 ~ 25 - Hole Chamfer general steel[◎] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] Single blade NA Available TiAlN - From: ₹ 1,672.40 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

TiAlN Coated High-Speed Steel Countersink, with Holes / 90°

MISUMI

It is effective in hole chamfering and deburring of light metals.

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Cobalt HSS 10 ~ 25 - Hole Chamfer general steel[◎] / Stainless Steel[○] / Cast Iron[○] / Aluminum[◎] / Copper[◎] Single blade NA Available TiAlN - From: ₹ 1,568.80 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

TiN-Coated High-Speed Steel Countersink, with Holes / 90°

MISUMI

Frequently used standard sizes are offered at affordable prices

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) Cobalt HSS 10 ~ 35 - Hole Chamfer general steel[◎] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] Single blade NA Available TiN - From: ₹ 1,071.17 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

TiN-Coated High-Speed Steel Center Drill, Regular Model

MISUMI

Frequently used standard sizes are offered at affordable prices

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) High-speed steel 1 ~ 4 - Centering (Positioning) general steel[◎] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] Double-edged NA Available TiN - From: ₹ 740.00 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

TiN-Coated High-Speed Steel Countersink / 3-Flute / 90°, 6-Size Set

MISUMI

Frequently used standard sizes are offered in a set at an affordable price

Tool Material Type Tool Diameter (D)(mm) Tip angle (θ) Application work material Single blade, two blades Peripheral Blade Y/N Coating Y/N Coating Type R Size (R)(mm) High-speed steel 6.3/8.3/10.4/12.4/16.5/20.5 - Hole Chamfer general steel[◎] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] Single blade NA Available TiN - From: ₹ 6,868.00 Days to Ship: Same day  Same day

Same day

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Tool Material Type |

| Tool Diameter (D)(mm) |

| Tip angle (θ) |

| Application |

| work material |

| Single blade, two blades |

| Peripheral Blade Y/N |

| Coating Y/N |

| Coating Type |

| R Size (R)(mm) |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| Brand | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI |

| Product Series | TiAlN Coated Carbide Center Drill, 60° Chamfering Model / Regular, Long | TiAlN Coated Carbide Countersink, 3-Flute / 90°, Regular, Long Shack | TiAlN Coated Carbide NC Spot Drill, Small Diameter, Multi-Functional Model | TiAlN Coated High-Speed Steel NC Spot Drill, Multi-Functional Model | TiAlN Coated High-Speed Steel NC Spot Drill, Regular, Long Shack | TiAlN Coated High-Speed Steel Center Drill, 90° Chamfering Model | TiAlN Coated High-Speed Steel Countersink, 3-Flute / 90°, Regular, Long Shack Model | TiN-Coated High-Speed Steel Countersink / 3-Flute / 90°, 6-Size Set | |||||||||||||||

| CAD |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

| From | ₹ 259.00- | ₹ 3,648.20- | ₹ 3,078.40- | ₹ 392.20- | ₹ 4,580.60- | ₹ 407.00- | ₹ 976.00- | ₹ 2,464.20- | ₹ 1,998.00- | ₹ 4,306.80- | ₹ 1,598.40- | ₹ 999.00- | ₹ 1,480.00- | ₹ 902.80- | ₹ 902.80- | ₹ 1,036.00- | ₹ 1,472.87- | ₹ 1,724.20- | ₹ 1,672.40- | ₹ 1,568.80- | ₹ 1,071.17- | ₹ 740.00- | ₹ 6,868.00 |

| Days to Ship | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | Same day |

| Tool Material Type | High-speed steel | Carbide | Carbide | High-speed steel | Carbide | Cobalt HSS | High-speed steel | Carbide | Carbide | Carbide | Cobalt HSS | Cobalt HSS | High-speed steel | High-speed steel | High-speed steel | High-speed steel | High-speed steel | Cobalt HSS | Cobalt HSS | Cobalt HSS | Cobalt HSS | High-speed steel | High-speed steel |

| Tool Diameter (D)(mm) | 1 ~ 5 | 0.3 ~ 2 | 0.5 ~ 5 | 1 ~ 5 | 6.3 ~ 20.5 | 2 ~ 20 | 1 ~ 4 | 0.5 ~ 2 | 2 ~ 12 | 1 ~ 4 | 3 ~ 12 | 2 ~ 12 | 1 ~ 4 | 1 ~ 4 | 1 ~ 4 | 1 ~ 5 | 6.3 ~ 20.5 | 6.3 ~ 20.5 | 10 ~ 25 | 10 ~ 25 | 10 ~ 35 | 1 ~ 4 | 6.3/8.3/10.4/12.4/16.5/20.5 |

| Tip angle (θ) | - | - | - | - | - | 90 ~ 120 | - | 60 ~ 120 | 90 ~ 120 | - | 90 | 90 | - | - | - | - | - | - | - | - | - | - | - |

| Application | Centering (Positioning) | Centering (Positioning) / Hole Chamfer | Centering (Positioning) | Centering (Positioning) | Hole Chamfer | Centering (Positioning) / Hole Chamfer | Centering (Positioning) | Centering (Positioning) / Hole Chamfer | Centering (Positioning) / Hole Chamfer | Centering (Positioning) | Centering (Positioning) / Hole Chamfer | Centering (Positioning) / Hole Chamfer | Centering (Positioning) | Centering (Positioning) | Centering (Positioning) | Centering (Positioning) | Hole Chamfer | Hole Chamfer | Hole Chamfer | Hole Chamfer | Hole Chamfer | Centering (Positioning) | Hole Chamfer |

| work material | general steel[○] | general steel[◎] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[◎] / Aluminum[◎] / Copper[◎] | general steel[◎] / Quenched and tempered steel[○] / high hardness steel[○] / Stainless Steel[○] / Cast Iron[◎] / Aluminum[◎] / Copper[◎] | general steel[○] | general steel[◎] / Quenched and tempered steel[◎] / high hardness steel[○] / Stainless Steel[○] / Cast Iron[◎] / Aluminum[◎] / Copper[◎] | general steel[○/◎] / Quenched and tempered steel[○] / Stainless Steel[○] / Aluminum[○] / Copper[○] | general steel[◎] / high hardness steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | general steel[◎] / Quenched and tempered steel[◎] / high hardness steel[○] / Stainless Steel[○] / Cast Iron[◎] / Aluminum[◎] / Copper[◎] | general steel[◎] / Quenched and tempered steel[◎] / Stainless Steel[○] / Cast Iron[◎] / Aluminum[◎] / Copper[◎] | general steel[◎] / Quenched and tempered steel[◎] / high hardness steel[○] / Stainless Steel[○] / Cast Iron[◎] / Aluminum[◎] / Copper[◎] | general steel[◎] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | general steel[◎] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | general steel[◎] / high hardness steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | general steel[◎] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | general steel[◎] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | general steel[○] | general steel[◎] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | general steel[◎] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | general steel[◎] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | general steel[◎] / Stainless Steel[○] / Cast Iron[○] / Aluminum[◎] / Copper[◎] | general steel[◎] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | general steel[◎] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] | general steel[◎] / Quenched and tempered steel[○] / Stainless Steel[○] / Cast Iron[○] / Aluminum[○] / Copper[○] |

| Single blade, two blades | Double-edged | Single blade | Double-edged | Double-edged | Single blade | Single blade | Double-edged | Single blade | Single blade | Double-edged | Single blade | Single blade | Double-edged | Double-edged | Double-edged | Double-edged | Single blade | Single blade | Single blade | Single blade | Single blade | Double-edged | Single blade |

| Peripheral Blade Y/N | NA | NA | NA | NA | NA | NA | NA | Available | NA | NA | NA | NA | NA | NA | NA | NA | NA | NA | NA | NA | NA | NA | NA |

| Coating Y/N | NA | NA | Available | NA | Available | Available / NA | Available | Available | Available | Available | Available | Available | Available | Available | Available | NA | Available | Available | Available | Available | Available | Available | Available |

| Coating Type | - | - | TiAlN | - | TiAlN | TiN / Non-Coated | TiAlN | TiAlN | TiAlN | TiAlN | TiAlN | TiAlN | TiAlN | TiAlN | TiAlN | - | TiN | TiAlN | TiAlN | TiAlN | TiN | TiN | TiN |

| R Size (R)(mm) | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

Loading...

Configure

Specification/Dimensions

-

Tool Material Type

-

Tool Diameter (D)(mm)

- 0.02

- 0.03

- 0.04

- 0.05

- 0.06

- 0.07

- 0.08

- 0.09

- 0.1

- 0.11

- 0.12

- 0.13

- 0.14

- 0.15

- 0.16

- 0.17

- 0.18

- 0.19

- 0.2

- 0.21

- 0.22

- 0.23

- 0.24

- 0.25

- 0.26

- 0.27

- 0.28

- 0.29

- 0.3

- 0.35

- 0.4

- 0.45

- 0.5

- 0.55

- 0.6

- 0.65

- 0.7

- 0.75

- 0.8

- 0.85

- 0.9

- 0.95

- 1

- 1/8

- 1/16

- 1/32

- 1/64

- 1.1

- 1.2

- 1.25

- 1.3

- 1.4

- 1.5

- 1.6

- 1.7

- 1.8

- 1.9

- 2.

- 2

- 2.1

- 2.2

- 2.3

- 2.4

- 2.5

- 2.6

- 2.7

- 2.8

- 2.9

- 3

- 3/16

- 3/32

- 3/64

- 3.1

- 3.15

- 3.2

- 3.5

- 3.8

- 4

- 4.3

- 5

- 5/16

- 5/32

- 5/64

- 5.3

- 5.8

- 6

- 6.3

- 6.3,8.3,10.4,12.4,16.5,20.5

- 6.30/8.30/10.40/12.40/16.50/20.50

- 6.3/8.3/10.4/12.4/16.5/20.5

- 6.35

- 7

- 7.3

- 7.7

- 8

- 8.3

- 9

- 9.4

- 9.5

- 9.52

- 10

- 10.4

- 11

- 11.2

- 11.5

- 12

- 12.4

- 12.5

- 12.7

- 13

- 13.4

- 14

- 14.4

- 15

- 15.87

- 16

- 16.5

- 18

- 18.5

- 19

- 19.05

- 20

- 20.5

- 21

- 22

- 22.5

- 23

- 25

- 25.0(+0.3)

- 26

- 27

- 28

- 30

- 31

- 31.5

- 32

- 34

- 35

- 36

- 37

- 40

- 45

- 46

- 50

- 55

- 60

- 63

- 65

- 70

- 75

- 80

- 90

- 95

- 100

-

Tip angle (θ)

-

Application

-

Centering (Positioning)

-

Hole Chamfer

-

Chamfering/Horizontal

-

V Groove

-

Drilling

-

Other

-

Centering (Positioning)

-

work material

- general steel

- Quenched and tempered steel

- high hardness steel

- Stainless Steel

- Cast Iron

- Aluminum

- Titanium

- Copper

- Graphite

- Resin

-

Single blade, two blades

-

Peripheral Blade Y/N

-

Coating Y/N

-

Coating Type

-

R Size (R)(mm)

Narrow search by specifying Manufacturer

-

- MISUMI (23)

- YAMAWA MFG (47)

- IWATA TOOL (30)

- GUHRING (23)

- EIKOSHA (9)

- ILIX (8)

- OKABE (7)

- ATOM (6)

- NOGA JAPAN (6)

- ESCO (4)

- KYOWA SEIKO (4)

- DIXI (3)

- OSG (3)

- TRUSCO NAKAYAMA (3)

- TAIYO-TOOL (3)

- WATERMILLS (3)

- THE CUT (2)

- DIJET (1)

- RYOCO SEIKI (1)

- SKC (1)

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy