(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

MISUMI, Parts Cleaner MPCL840【1-30 Pieces Per Package】 (MPCL840-1)

- Standard Unit Price:

- ₹ 350.00-

- Days to Ship :

- Same day

(i)

Caution

- This product is DG item and transportation is GROUND ONLY.

-

- Order Qty :

-

-

- Starting From :

- ₹ 350.00 /Unit

-

- Total Price :

- ---

-

- Days to ship :

- ---

Select part number to Order Now/ Add to Cart

Basic Specifications

-

- Function

- Powerful / Fast-Drying

-

- Model

- Spray

-

- Color

- No Color

Product Description

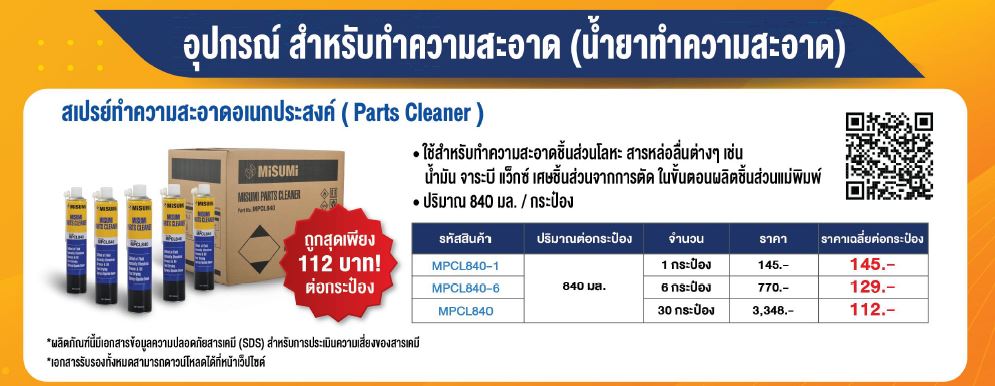

Large capacity, powerful, quick-drying type detergent. Use for degreasing lubricant, grease and wax adhered to metal parts and molds and blue varnish removal after marking work. Spray which can be used even when the can is in an inverted position.

[Features]

1) Excellent washing and degreasing properties for firmly removing stubborn dirt adhered to metal parts such as bearings, chains, and gears.

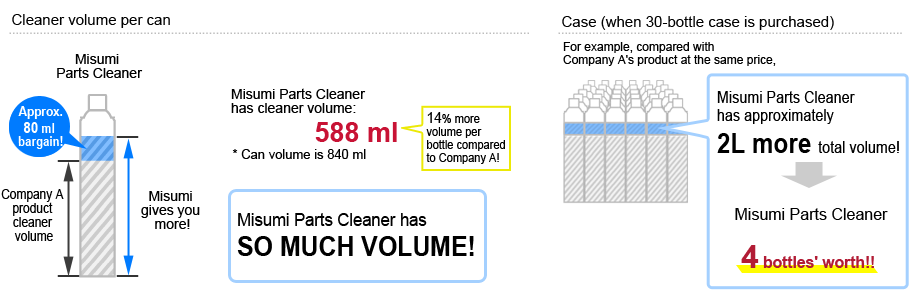

2) 1 bottle contains 588 ml of solvent. Parts cleaner which boasts an excellent cost performance

[Capacity (per 1 spray can)] / NET. 840 ml / (Petroleum hydrocarbon) 588 ml

[Packaging format at delivery] Cardboard [Country of origin] China

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer tomanufacturer catalogs.

The product list can be filtered using the selections found beneath the specification item name.

Specifications

Part cleaner So much volume, such a bargain! Compare for yourself the cleaner volume per bottle

Comparing unit price per 1 ml…

| MPCL840 | A Company Product | B Company ผลิตภัณฑ์ | |

|---|---|---|---|

| Price (Regular Price) | 145 | 174 | 167 |

| Volume per Bottle | 588ml | 504ml | 546ml |

| Price per 1 ml | 0.25 | 0.35 | 0.31 |

Product Specifications and Applications Part cleaner

Product Specifications

| Structure | Form | Type | Main Component | Material Name | Composition Ratio (wt%) | Liquid Color |

|---|---|---|---|---|---|---|

| Aerosol | Spray | Large Capacity / Strong / Quick Drying | Aliphatic Hydrocarbon LPG | Isohexane | 55 to 65% | Colorless and Transparent |

| Ethanol | 10 to 20% | |||||

| LPG | 20 to 30% | |||||

| CO2 | 1 to 4% |

| Part Number | Quantity | Volume (per 1 spray can) | Size | Accessory | Other Functions |

|---|---|---|---|---|---|

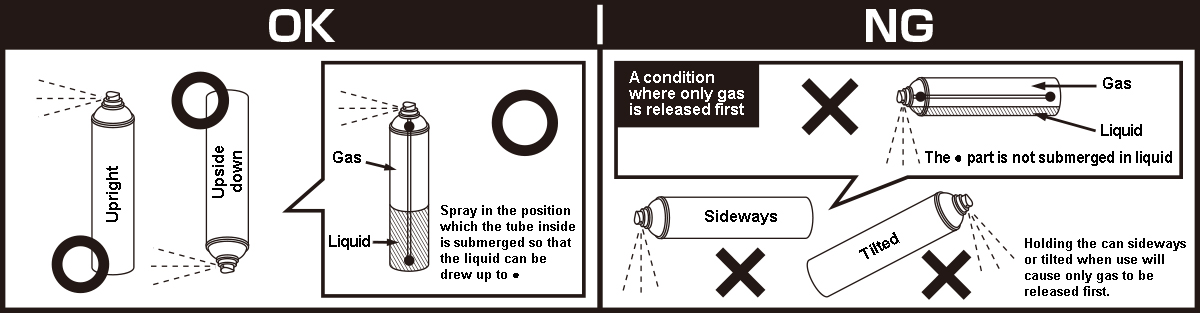

| MPCL840 | 1 box (30 cans per box) | NET. 840ml Class 4 type 1 petroleum (petroleum hydrocarbon) 588 ml | Spray Can Diameter × Height 65mm×340mm | Spray Nozzle (Approx. 140 mm) × 1 piece | Able to inject in an inverted position |

* Part number "MPCL840" is an order number for 1 box (30 pieces). The spray can is not sold separately.

Applications

- Clean oil and grease off mechanical metal parts such as cylinders and bearings.

- Remove cutting oil and chips during parts molding.

- Clean mold lubricants, wax and rust inhibitor.

- Remove coloring agent scribble such as blue varnish.

- Clean off oil from jigs and tools.

- Remove fats, dust, carbon and the like from brake linings, brake drums and discs.

- Degreasing in car maintenance.

- * When storing parts, it is recommended to apply rust inhibitor after cleaning with Parts Cleaner.

- * Do not use with any rubber or plastic products such as O-ring.

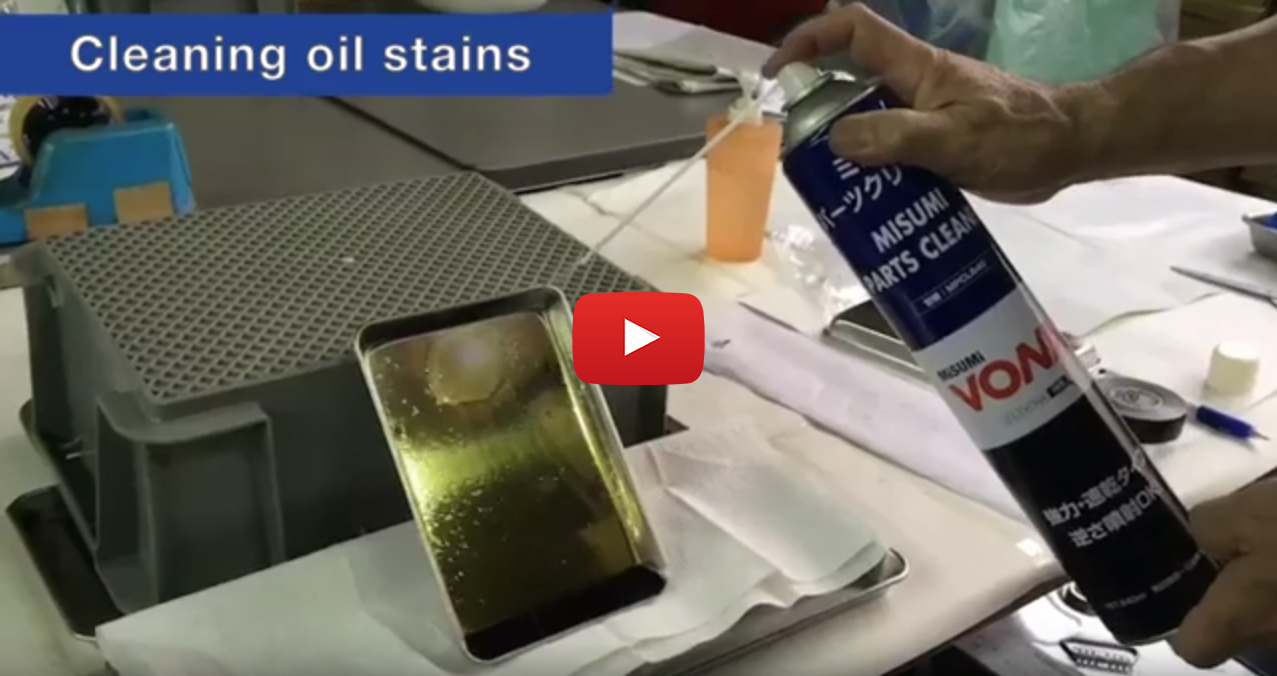

Demonstration of Performance Part cleaner

Oil Cleaning

Apply machine oil to a test panel (20 cm × 15 cm) equally. Use Spray Nozzle to spray Parts Cleaner MPCL840 for approximately 6 seconds.

* The product in the video is a former design. The design has been updated since December, 2018 without changes in ingredients or volume.

Although the design of the package may be different from the videos, the content of the product has not been changed.

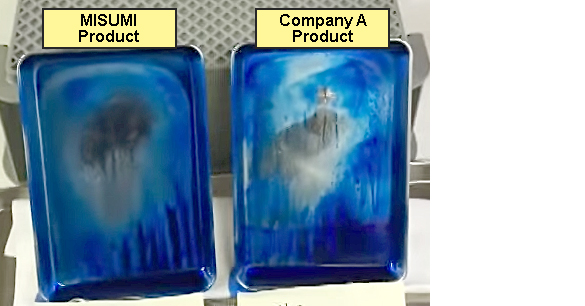

Blue Varnish Cleaning Comparison Test

Apply blue varnish to both test panels (20 cm × 15 cm) equally. Use Spray Nozzle to spray Parts Cleaner MPCL840 and Company A Parts Cleaner for the same duration. We can see the difference between the amount of blue varnish removed.

* The product in the video is a former design. The design has been updated since December, 2018 without changes in ingredients or volume.

It takes only half volume of Parts Cleaner MPCL840 to get the same amount of panel cleaned, compared to Company A Parts Cleaner.

It takes only half volume of Parts Cleaner MPCL840 to get the same amount of panel cleaned, compared to Company A Parts Cleaner.

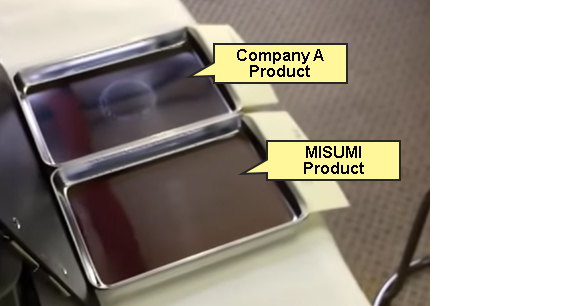

Remaining Traces Comparison Test

Apply ointment to both test panels (20 cm × 15 cm) equally. Use Spray Nozzle to spray Parts Cleaner MPCL840 and Company A Parts Cleaner for the same duration. We can see the difference between the remaining traces of sprayed solvent after natural drying.

* The product in the video is a former design. The design has been updated since December, 2018 without changes in ingredients or volume.

For Company A Parts Cleaner, we can clearly see the residue of white circle mark. With Parts Cleaner MPCL840, we can barely see any traces remained from the injection.

Although the design of the package may be different from the videos, the content of the product has not been changed.

How to Use and Precaution for Use Part cleaner

How to Use

- Spray on parts to be cleaned so that all the dirt is washed away.

- Use cloth, non-woven fabric or brush with the spray when cleaning persistent dirt.

Precaution for Use

- Keep away from high-temperature ignition source such as heat, sparks, open flames, etc.

- Use the product outdoors or in a well-ventilated environment. Even when it is used outdoors, be careful of the wind direction to prevent the inhalation of solvent vapors while spraying.

- Perform an injection by holding the can sideways or tilted will release only gas, and the solvent inside will not be used up.

- For further information other than above, please refer to Safety Data Sheet (SDS).

Perform an injection by holding the can sideways will release only gas, and the solvent inside will not be used up.

Environmental Considerations Part cleaner

At MISUMI, we follow the "Green Procurement Guidelines," which take into account the safety, recyclability, energy savings and so on, to supply the products with lower environmental impact by supporting actions complying with laws and regulations of chemical substances and other requirements.

Safety Data Sheet (SDS) for chemical substance risk assessment is also available.

SDS (MSDS)

Includes information about GHS classification, Japan's CSCL/ISHA and PRTR law.

For more information, please see the following reference. (Available in PDF format)

SAFETY DATA SHEET (SDS)(PDF / 136KB)

Frequently asked question (FAQ)

- Question: Does the parts cleaner MPCL840 meet the Organic Solvent Poisoning Prevention Regulations?

- Answer: Not applicable.

- Question: Does the parts cleaner MPCL840 contain silicone?

- Answer: It does not contain silicone.

- Question: The SDS of the parts cleaner MPCL840 says that it contains 3.0% normal hexane, but is it not applicable to the PRTR method?

- Answer: Since the amount of normal hexane contained in the parts cleaner MPCL840 is extremely small, it does not fall under the PRTR method.

- Question: Is sideways spray possible?

- Answer: It can be used upside down, but not sideways. There is a risk that gas will leak and spraying will not be possible while the bottle is being held sideways.

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy