(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

Specification/Dimensions

-

Locating Side Outer Dia. P (Ø)(mm)

-

Mounting Side Outer Dia. D(mm)

-

type

- C-JPQB

- C-JPQD

-

Insertion Guide Tip Shape

-

Round

Round -

Diamond

Diamond

-

-

CAD

- 2D

- 3D

Days to Ship

-

- All

- Same day

Specify Alterations

Large Head Locating Pins - Spherical

- Volume Discount

Copy Part Number URL to Clipboard

The part number URL has been copied into your clipboard.-

- Order Qty :

-

-

- Total Price :

- ---

-

- Days to ship :

- ---

Select part number to Order Now/ Add to Cart

Product Description

- Large Head Locating Pins – Spherical tip type, C-JPQB / C-JPQD series from MISUMI.

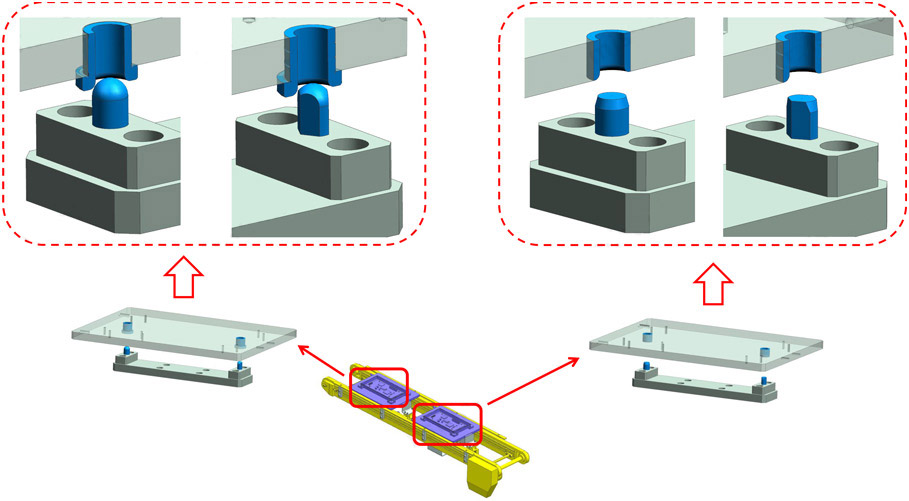

- Standard type with spherical head. Rod diameter tolerance that can be specified for the press-fit part and lead-in part: m6, p6.

- The mounting method is press-fit type, which is simple and convenient.

- Optional Material: Iron (SKS3); Stainless Steel (SUS304, SUS440C), suitable for positioning of a variety of workpieces.

- SUS304 Material, effectively ensuring anti-rust.

- The lead-in part of the sphere can make the workpiece lead in by sliding sideways, without damage.

Economy Spherical Locating Pin

- Standard type with spherical head for smooth positioning

- Press-fit mounting simplifies the installation process

- Made from SKS3 or SUS304 for durability

- Ensures anti-rust performance with SUS304 material

- Spherical lead-in part protects workpiece from damage

![]()

MISUMI Standard

![]()

Cheaper Price

![]()

Product Variety

![]()

3D CAD Support

| Material No. | Type | Locating Pins Status |  Material Material |  Hardness Hardness |

| m6 | ||||

| ① | C-JPQB | Round | Equivalent to SKS3 | 60~63HRC |

| ② | C-JPQD | Polygonal type |

|  Part Number Part Number | - |  P P | |

| C-JPQB6 | - | 8 |

■ Dimension Specification Table

| Part number |  P Selection P Selection | L | B | C | (W) | ||||||||

Type Type |  D D | D tolerance | |||||||||||

| m6 | |||||||||||||

| <Round type> C-JPQB <Polygonal type> C-JPQD | 2 | +0.008 +0.002 | 3 | 4 | 3 | 0.5 | 1.2 | ||||||

| 3 | 4 | 5 | 5 | 5 | 1.5 | ||||||||

| 4 | +0.012 +0.004 | 5 | 6 | 6 | 1 | 1.8 | |||||||

| 5 | 6 | 8 | 10 | 2.2 | |||||||||

| 6 | 8 | 10 | 8 | 3 | |||||||||

| 8 | +0.015 +0.006 | 10 | 12 | 15 | 1.5 | 3.5 | |||||||

| 10 | 12 | 10 | 2 | 4 | |||||||||

| Lithium battery | Semiconductor | Medical | ||

|  |  | ||

| Smart phone | Electronic & Electrical Appliances | Robotics | ||

|  |  |

Part Number

- Incomplete part number.

Please use left hand selections to complete a part number.

| Part Number |

|---|

| C-JPQD2-3 |

| C-JPQD3-4 |

| C-JPQD3-5 |

| C-JPQD4-5 |

| C-JPQD4-6 |

| C-JPQD5-6 |

| C-JPQD5-8 |

| C-JPQD6-8 |

| C-JPQD6-10 |

| C-JPQD8-10 |

| C-JPQD8-12 |

| C-JPQD10-12 |

| Part Number | Price | Minimum Order Qty. | Volume Discount | Days to Ship | RoHS | Insertion Guide Tip Shape | Locating Side Outer Dia. P (Ø) (mm) | Mounting Side Outer Dia. D (mm) |

|---|---|---|---|---|---|---|---|---|

₹ 321.00 | 1 Piece(s) | Available | Same day | 10 | Diamond | 3 | 2 | |

₹ 319.00 | 1 Piece(s) | Available | Same day | 10 | Diamond | 4 | 3 | |

₹ 322.00 | 1 Piece(s) | Available | Same day | 10 | Diamond | 5 | 3 | |

₹ 316.00 | 1 Piece(s) | Available | Same day | 10 | Diamond | 5 | 4 | |

₹ 317.00 | 1 Piece(s) | Available | Same day | 10 | Diamond | 6 | 4 | |

₹ 313.00 | 1 Piece(s) | Available | Same day | 10 | Diamond | 6 | 5 | |

₹ 313.00 | 1 Piece(s) | Available | Same day | 10 | Diamond | 8 | 5 | |

₹ 308.00 | 1 Piece(s) | Available | Same day | 10 | Diamond | 8 | 6 | |

₹ 308.00 | 1 Piece(s) | Available | Same day | 10 | Diamond | 10 | 6 | |

₹ 320.00 | 1 Piece(s) | Available | Same day | 10 | Diamond | 10 | 8 | |

₹ 326.00 | 1 Piece(s) | Available | Same day | 10 | Diamond | 12 | 8 | |

₹ 326.00 | 1 Piece(s) | Available | Same day | 10 | Diamond | 12 | 10 |

Loading...

Basic Information

| Basic Shape | Large Head | Insertion Guide Tip Type | Spherical | Insertion Guide Specifications | Not Provided |

|---|---|---|---|---|---|

| Mounting Side Shape | Straight (Press-Fit) | Surface Treatment | Not Provided | Heat Treatment | Directly Quenching |

| Material | SKS3 Equivalent | Locating Side O.D. Tolerance | -0.01/-0.02 | Mounting Side Tolerance | m6 |

| Dimension Configurable Type | P Fixed |

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Frequently asked question (FAQ)

- Question: Will the positioning pin rust?

- Answer: Products without surface treatment will rust. It is recommended to regularly apply antirust oil for maintenance or choose products with surface treatment (no-electro nickel plated), which can prevent rust in normal atmospheric environments. No-electro nickel plated surface can effectively prevent rust.

- Question: What tools are suitable for measurement of positioning pin outer diameter?

- Answer: If the outer diameter tolerance of the positioning pin is within 0.02mm, common vernier calipers and other measuring tools with general accuracy are not suitable. It is recommended to use a high accuracy external plug gauge or an internal micrometer for measurement.

- Question: Will the outer diameter of the positioning pin become smaller after installation?

- Answer: It will become smaller, and m6 will shrink more than p6 after installation, so please pay attention during hole machining. For detailed change values, please refer to the precautions: change in inner diameter of the fixture bushing during press-fit.

- Question: What are the options for positioning pin outer diameter tolerance?

- Answer: Optional tolerances for the outer diameter of positioning pin: m6, p6, m7, g7. Basically it can meet the needs of installation and positioning under general conditions.

- Question: What fixture bushings are commonly used together with positioning pins?

- Answer: The fixture bushing is of basic shape, which is usually suitable for supporting positioning pins, checking insertion pins for fixtures, etc.

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy