Understanding Industrial Temperature Controllers

Publish Date: 14 Nov 2025

Achieving thermal stability is non-negotiable for high-quality, efficient industrial processes. The Temperature Controller is a critical, precise instrument at the core of any thermal management system, ensuring that production environments meet stringent temperature requirements consistently.

This article defines the Temperature Controller, explores its indispensable functions in industrial automation, and provides engineers with a clear, systematic framework for selecting the exact controller required for demanding applications.

What are Temperature Controllers?

A Temperature Controller is a highly specialized piece of equipment designed to automatically regulate temperature within a defined system.

Functionally, the controller receives the real-time temperature data from a sensor (the Process Value or PV) and compares it against the engineer-defined target temperature (Set Point or SV). Based on the calculated difference, the controller calculates and generates a precise output signal to modulate the operation of the connected heating or cooling hardware, maintaining the target temperature with minimal deviation.

The Essential Functions of Temperature Controllers

The accurate operation of these devices is crucial for high-quality industrial output and system longevity:

- Precise Temperature Control: Guarantees the process temperature is held constant at the set value, vital for chemical reactions and material processing.

- Improved Production Efficiency: Prevents process variations caused by thermal drift, minimizing product defects and reducing expensive machine downtime.

- Maintain Product Quality: Ensures every production batch adheres to strict thermal standards, resulting in guaranteed uniformity and performance of the final product.

- Energy Optimization: By intelligently managing heating and cooling cycles, controllers reduce unnecessary energy consumption and contribute to lower operational expenditure.

How Temperature Controllers Work in Practice

A typical temperature control cycle involves constant feedback and adjustment:

- Sensing: The Temperature Controller receives the current temperature signal (PV) from a sensor (e.g., a thermocouple or RTD).

- Comparison & Calculation: The controller displays the PV and the SV, then rapidly compares the two. It calculates the necessary adjustment based on the selected control logic (most often PID).

- Output & Actuation: It sends a precisely calculated control output signal (e.g., Relay, Voltage, or Current) to an actuator (such as a heater, valve, or contactor) to modulate operation and maintain stable target temperature.

Selecting a Temperature Controller: A Framework for Precision

Choosing the correct temperature control device is paramount for achieving process quality. Engineers must carefully consider the following technical specifications:

Sensor Type Compatibility

The sensor defines the controller's thermal measurement capabilities. The choice must match the application's required temperature range and accuracy:

- Thermocouples (J, K, T, E): Best for measuring a wide range of temperatures (low to very high, up to 1200∘C depending on type) and environments with rapidly changing thermal conditions.

- RTD (Resistance Temperature Detector, e.g., Pt100): Offers superior accuracy and stability. Ideal for applications requiring extremely precise temperature measurement within a narrower, defined range (typically −200∘C to 850∘C).

Operating Temperature Range

Ensure the Temperature Controller itself is rated to safely support the full range of temperatures the process will encounter. Exceeding a controller's specified temperature limit will inevitably lead to equipment damage and control failure.

Control Function Complexity

Select the control method that aligns with your precision requirements:

- ON/OFF Control: A simple, binary function for switching equipment on or off when the temperature crosses the set point. Suitable only for basic systems that do not require high precision.

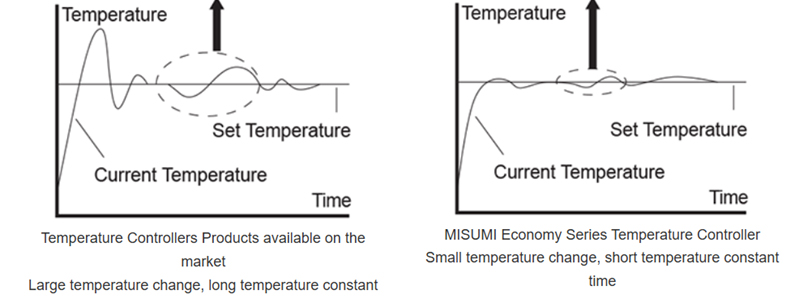

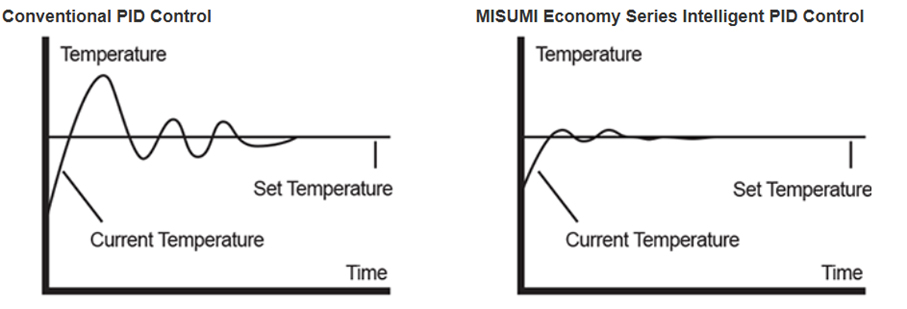

- PID Control (Proportional, Integral, Derivative): The industry standard for high-accuracy temperature regulation. It uses continuous calculation to minimize temperature overshoots and undershoots, guaranteeing highly stable, tight control (essential for processes like industrial ovens or complex fluid systems).

Output Signal Type

The controller's output must be compatible with the heating or cooling load it is designed to drive:

- Relay Output: Simple electrical switching, suitable for small loads and systems where load cycling is infrequent.

- SSR (Solid State Relay) Output: High-durability, solid-state switching ideal for precise, high-speed control applications that require very frequent on/off cycling of the load.

- Analog Output (e.g., 4–20 mA or 0–10 V): Delivers a continuous signal for systems that require modulating control (e.g., adjusting the power supplied to a heater or positioning a control valve).

Configure Your Control System with MiSUMi

Temperature Controllers are fundamental components for achieving the consistency and precision necessary in modern manufacturing. By considering sensor selection, temperature range, and control logic, you can configure a thermal management system that ensures operational excellence.

Explore MiSUMi’s Temperature Controllers and accessories to source the exact, high-performance device required for your industrial automation system.