(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

Pipes, Metal Tubes(Finishing Method:Polishing (1.6µm))

Brand |

|

|---|---|

| CAD |

|

| Days to Ship |

|

8 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

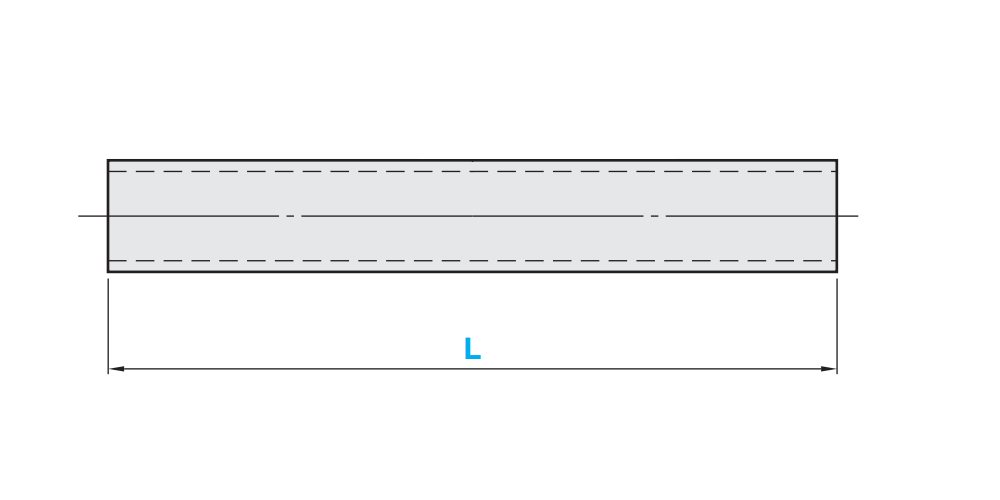

Thin-Walled Ground Stainless Steel Hollow Tubes

MISUMI

Wall thickness can be selected from ``0.3mm'', ``0.5mm'', and ``1.0mm''. Annealed materials are also ideal for “bending”! [Material] SUS304, SUS304 (annealed material) When bending the pipe, please use a pipe bending tool.

Outer Dia. D(Ø) Environmentally friendly Inner Dia. d(Ø) Characteristics/Applications Material Finishing Method Manufacturing Method Overall Length L(mm) Surface Treatment Thickness t Threading Female Thread [M] Male Thread [M] Cleaning Method 2 ~ 30 - 1 ~ 29 - SUS304 ~ SUS304 (Annealed Material) Polishing (1.6µm) Weld-On - - - - - - - Days to Ship: 8 Day(s) or more  8 Day(s) or more

8 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Thin-Walled Ground Stainless Steel Hollow Tubes - Precision I.D. / O.D.

MISUMI

Outer diameters from 0.5 to 5mm can be specified in 0.5mm increments! The "outer diameter polished finish" is also attractive! [Material] SUS304

Outer Dia. D(Ø) Environmentally friendly Inner Dia. d(Ø) Characteristics/Applications Material Finishing Method Manufacturing Method Overall Length L(mm) Surface Treatment Thickness t Threading Female Thread [M] Male Thread [M] Cleaning Method 0.5 ~ 5 - - - SUS304 Polishing (1.6µm) Seamless - - - - - - - Days to Ship: 10 Day(s) or more  10 Day(s) or more

10 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

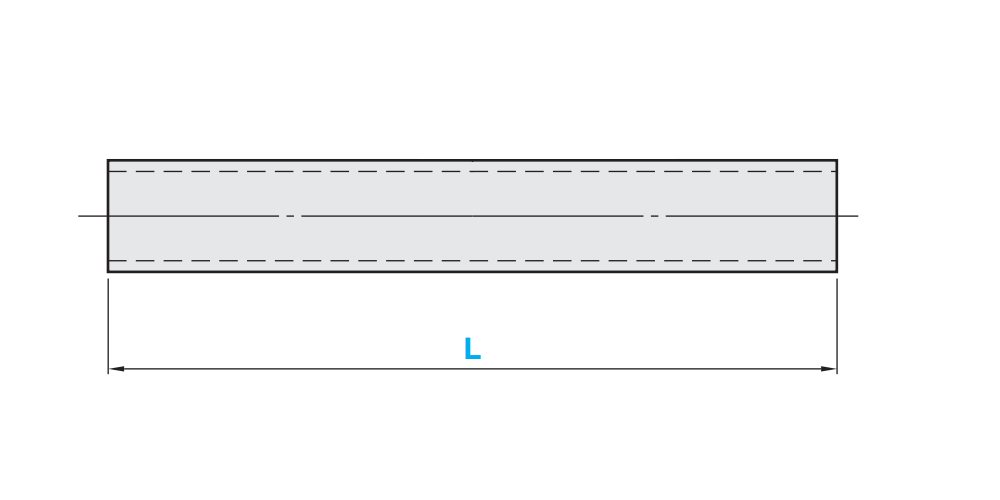

Thick-Walled Ground Stainless Steel Hollow Tubes - Straight Type

MISUMI

Finished with an outer diameter tolerance of "h8". Since it has been polished, it is possible to reduce the number of steps! [Material] SUS304

Outer Dia. D(Ø) Environmentally friendly Inner Dia. d(Ø) Characteristics/Applications Material Finishing Method Manufacturing Method Overall Length L(mm) Surface Treatment Thickness t Threading Female Thread [M] Male Thread [M] Cleaning Method 6 ~ 50 - 3 ~ 35 - SUS304 Polishing (1.6µm) Seamless - - - - - - - Days to Ship: 7 Day(s) or more  7 Day(s) or more

7 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

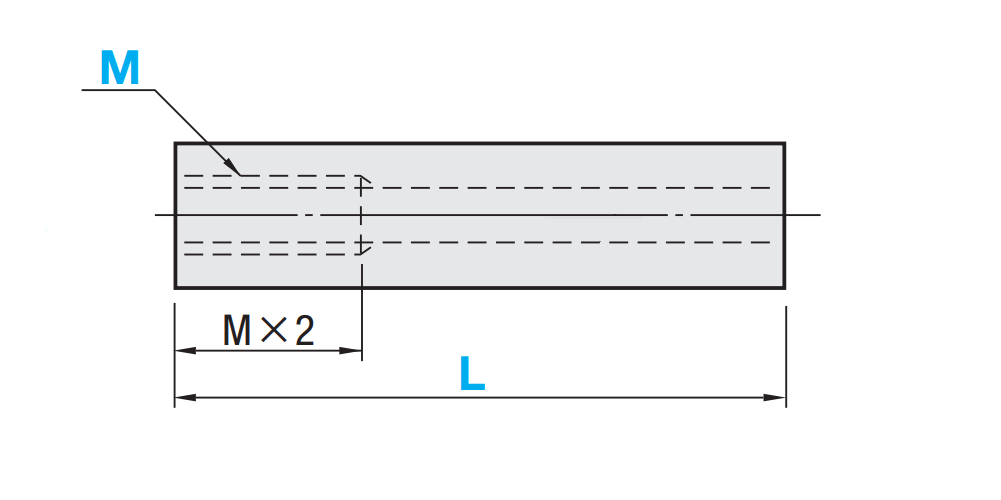

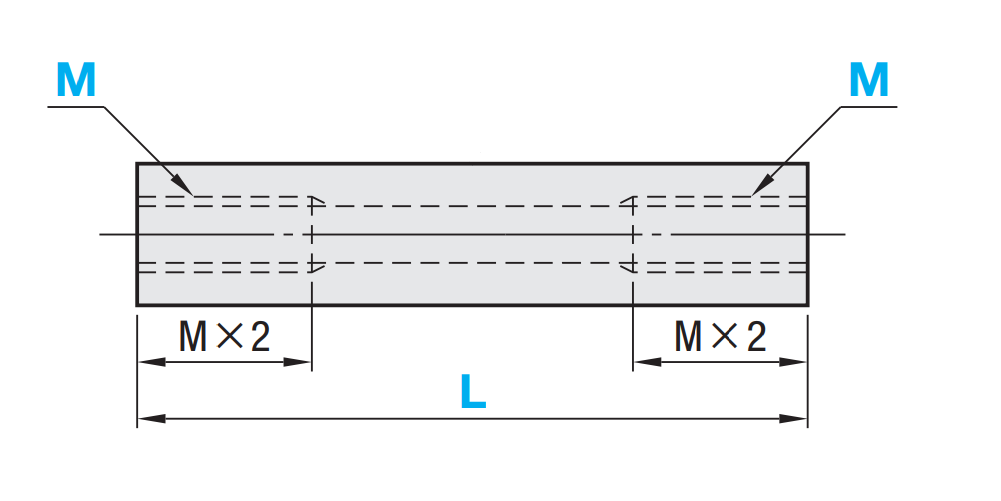

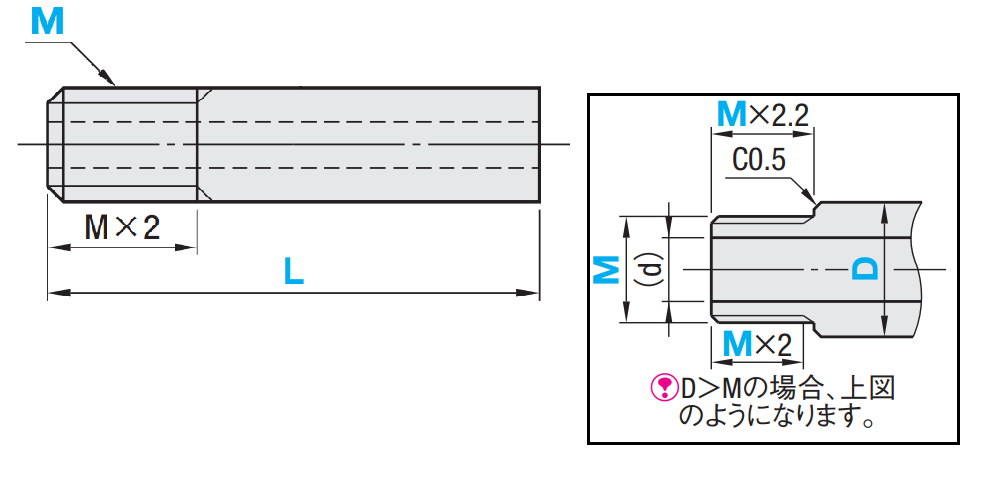

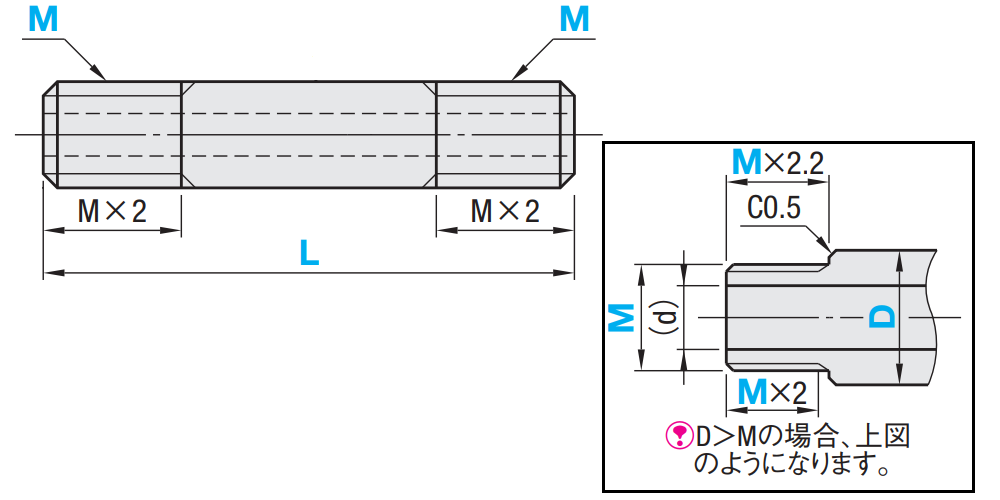

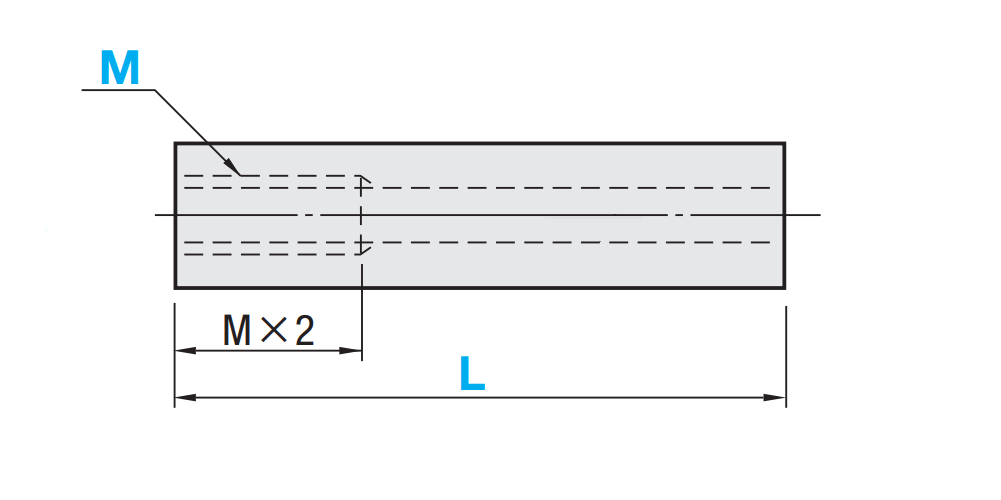

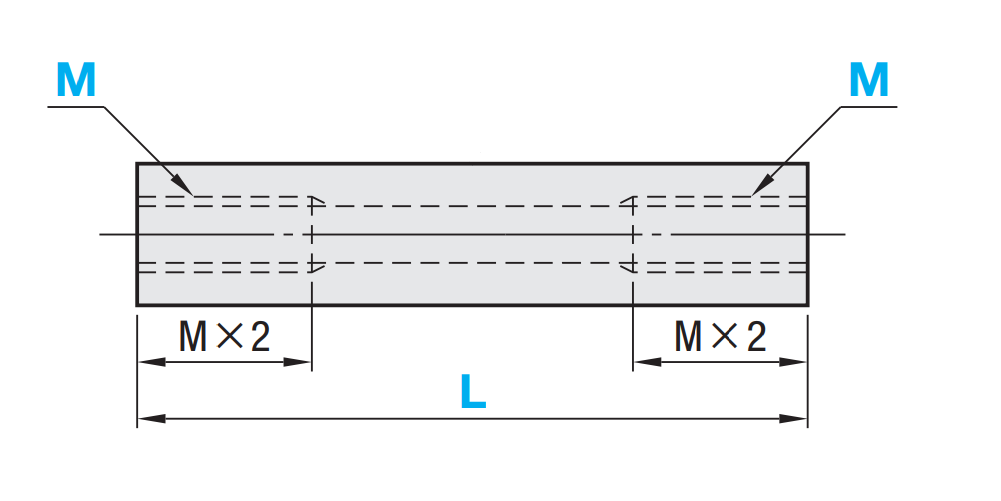

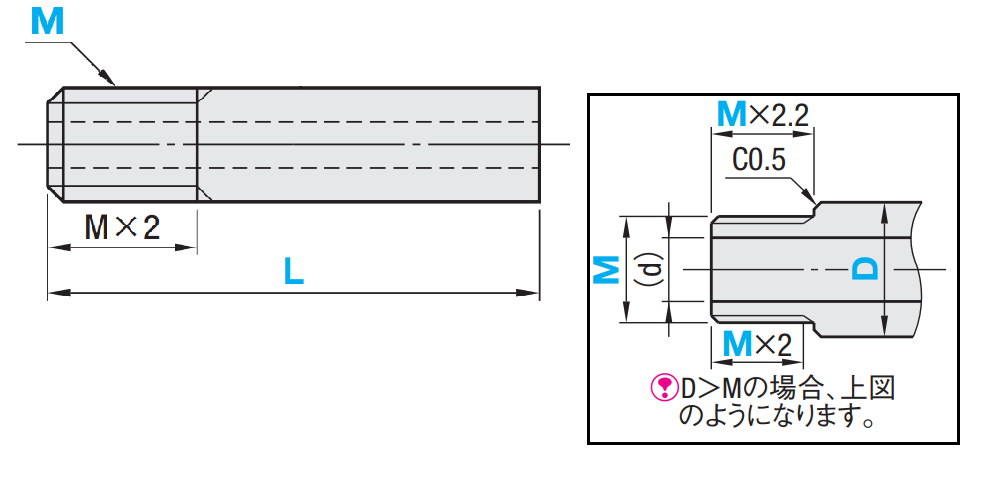

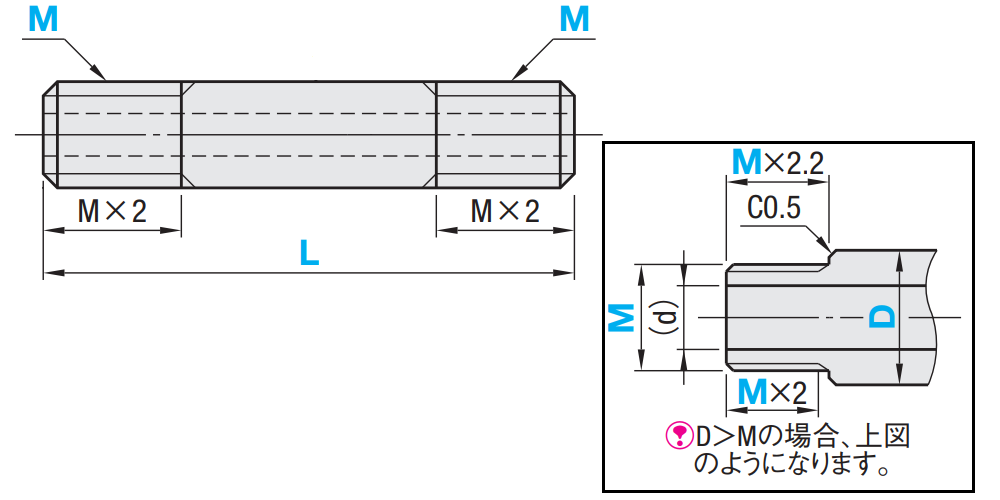

Thick-Walled Ground Stainless Steel Hollow Tubes - One End Threaded or Both Ends Threaded

MISUMI

Outer diameter tolerance "h8" and "shaft end male thread" processing allows for process reduction! [Material] SUS304

Outer Dia. D(Ø) Environmentally friendly Inner Dia. d(Ø) Characteristics/Applications Material Finishing Method Manufacturing Method Overall Length L(mm) Surface Treatment Thickness t Threading Female Thread [M] Male Thread [M] Cleaning Method 8 ~ 30 - - - SUS304 Polishing (1.6µm) Seamless - - - - - - - Days to Ship: 8 Day(s) or more  8 Day(s) or more

8 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

![[Clean & Pack]Thick-Walled Ground Stainless Steel Hollow Tubes](//content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/v1/p/jp/product/series/110310743489/110310743489_001_20230911105917.jpg?$product_view_b$)

[Clean & Pack]Thick-Walled Ground Stainless Steel Hollow Tubes

MISUMI

Three types of cleaning methods are available: degreasing, precision cleaning, and electrolytic polishing + precision cleaning. They can be ordered from one piece with the standard part number.

This eliminates the need for customer cleaning or outsourced cleaning, reducing the amount of time and effort required.■Part number for clean & pack products· Degreasing (anti-rust single packing) : part number SL-□□ · Precision cleaning (degassing double packing) : part number SH-□□ · Electrolytic polishing + precision cleaning (degassing double packing) : part number SHD-□□ Product part number Cleaning method Packaging type Effects Compared to Uncleaned Product Environment (Standard) Process SL-□□ Degreasing Anti-rust packing Oil removal General environment Regular assembly process Post battery assembly process SH-□□ Precision cleaning Degassing double packing Oil removal

Dust removalClean environment (Class 10 to 1,000) Battery assembly process LCD-related post assembly process In-vehicle camera assembly process SHD-□□ Electrolytic polishing + precision cleaning Degassing double packing Oil removal

Dust removal

Outgas reductionVacuum environment

Clean environment (Class 10 to 1,000)Pre-semiconductor process Liquid crystal deposition process Pre-OLED process ■Notes

Cleaning also removes rust prevention oil, which may make the product more susceptible to rusting than an uncleaned product.

Please be careful about the application location and storage environment.Finished with O.D. tolerance of h8. Since it has been polished, it is possible to reduce the number of manufacturing steps. [Material] SUS304

Outer Dia. D(Ø) Environmentally friendly Inner Dia. d(Ø) Characteristics/Applications Material Finishing Method Manufacturing Method Overall Length L(mm) Surface Treatment Thickness t Threading Female Thread [M] Male Thread [M] Cleaning Method 6 ~ 50 RoHS Compliant (10 Substances) 3 ~ 35 Clean Washed Stainless Steel Polishing (1.6µm) Seamless 10 ~ 800 Not Provided 1.5 ~ 8 N/A - - Degreasing / Precision Cleaning Days to Ship: 12 Day(s) or more  12 Day(s) or more

12 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

![[Clean & Pack]Thin-Walled Ground Stainless Steel Hollow Tubes](//content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/v1/p/jp/product/series/110310744839/110310744839_001_20230911105917.jpg?$product_view_b$)

[Clean & Pack]Thin-Walled Ground Stainless Steel Hollow Tubes

MISUMI

Three types of cleaning methods are available: degreasing, precision cleaning, and electrolytic polishing + precision cleaning. They can be ordered from one piece with the standard part number.

This eliminates the need for customer cleaning or outsourced cleaning, reducing the amount of time and effort required.■Part number for clean & pack products· Degreasing (anti-rust single packing) : part number SL-□□ · Precision cleaning (degassing double packing) : part number SH-□□ · Electrolytic polishing + precision cleaning (degassing double packing) : part number SHD-□□ Product part number Cleaning method Packaging type Effects Compared to Uncleaned Product Environment (Standard) Process SL-□□ Degreasing Anti-rust packing Oil removal General environment Regular assembly process Post battery assembly process SH-□□ Precision cleaning Degassing double packing Oil removal

Dust removalClean environment (Class 10 to 1,000) Battery assembly process LCD-related post assembly process In-vehicle camera assembly process SHD-□□ Electrolytic polishing + precision cleaning Degassing double packing Oil removal

Dust removal

Outgas reductionVacuum environment

Clean environment (Class 10 to 1,000)Pre-semiconductor process Liquid crystal deposition process Pre-OLED process ■Notes

Cleaning also removes rust prevention oil, which may make the product more susceptible to rusting than an uncleaned product.

Please be careful about the application location and storage environment.The wall thickness can be selected from 0.3 mm, 0.5 mm and 1.0 mm. Annealed materials are also ideal for bending. Materials SUS304, SUS304 (Annealed Material)

Outer Dia. D(Ø) Environmentally friendly Inner Dia. d(Ø) Characteristics/Applications Material Finishing Method Manufacturing Method Overall Length L(mm) Surface Treatment Thickness t Threading Female Thread [M] Male Thread [M] Cleaning Method 2 ~ 30 RoHS Compliant (10 Substances) 1 ~ 29 Clean Washed Stainless Steel Polishing (1.6µm) Weld-On 10 ~ 800 Not Provided 0.3 ~ 1 N/A - - Degreasing / Precision Cleaning Days to Ship: 12 Day(s) or more  12 Day(s) or more

12 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

![[Clean & Pack]Thick-Walled Ground Stainless Steel Hollow Tubes - One End and Both Ends Threaded](//content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/v1/p/jp/product/series/110310743579/110310743579_001_20230911105917.jpg?$product_view_b$)

[Clean & Pack]Thick-Walled Ground Stainless Steel Hollow Tubes - One End and Both Ends Threaded

MISUMI

Three types of cleaning methods are available: degreasing, precision cleaning, and electrolytic polishing + precision cleaning. They can be ordered from one piece with the standard part number.

This eliminates the need for customer cleaning or outsourced cleaning, reducing the amount of time and effort required.■Part number for clean & pack products· Degreasing (anti-rust single packing) : part number SL-□□ · Precision cleaning (degassing double packing) : part number SH-□□ · Electrolytic polishing + precision cleaning (degassing double packing) : part number SHD-□□ Product part number Cleaning method Packaging type Effects Compared to Uncleaned Product Environment (Standard) Process SL-□□ Degreasing Anti-rust packing Oil removal General environment Regular assembly process Post battery assembly process SH-□□ Precision cleaning Degassing double packing Oil removal

Dust removalClean environment (Class 10 to 1,000) Battery assembly process LCD-related post assembly process In-vehicle camera assembly process SHD-□□ Electrolytic polishing + precision cleaning Degassing double packing Oil removal

Dust removal

Outgas reductionVacuum environment

Clean environment (Class 10 to 1,000)Pre-semiconductor process Liquid crystal deposition process Pre-OLED process ■Notes

Cleaning also removes rust prevention oil, which may make the product more susceptible to rusting than an uncleaned product.

Please be careful about the application location and storage environment.O.D. Tolerance h8 and shaft end threaded processing allow process reduction. [Material] SUS304

Outer Dia. D(Ø) Environmentally friendly Inner Dia. d(Ø) Characteristics/Applications Material Finishing Method Manufacturing Method Overall Length L(mm) Surface Treatment Thickness t Threading Female Thread [M] Male Thread [M] Cleaning Method 8 ~ 30 RoHS Compliant (10 Substances) 4 ~ 16 Clean Washed Stainless Steel Polishing (1.6µm) Seamless 50 ~ 800 Not Provided 2 ~ 7 One-End Male Thread / Male Threads on Both Ends - 8 / 10 / 12 / 16 / 20 / 24 / 30 Degreasing / Precision Cleaning Days to Ship: 12 Day(s) or more  12 Day(s) or more

12 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

![[Clean & Pack]Thick-Walled Ground Stainless Steel Hollow Tubes - Precision I.D./O.D.](//content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/v1/p/jp/product/series/110310743939/110310743939_001_20230911105917.jpg?$product_view_b$)

[Clean & Pack]Thick-Walled Ground Stainless Steel Hollow Tubes - Precision I.D./O.D.

MISUMI

Three types of cleaning methods are available: degreasing, precision cleaning, and electrolytic polishing + precision cleaning. They can be ordered from one piece with the standard part number.

This eliminates the need for customer cleaning or outsourced cleaning, reducing the amount of time and effort required.■Part number for clean & pack products· Degreasing (anti-rust single packing) : part number SL-□□ · Precision cleaning (degassing double packing) : part number SH-□□ · Electrolytic polishing + precision cleaning (degassing double packing) : part number SHD-□□ Product part number Cleaning method Packaging type Effects Compared to Uncleaned Product Environment (Standard) Process SL-□□ Degreasing Anti-rust packing Oil removal General environment Regular assembly process Post battery assembly process SH-□□ Precision cleaning Degassing double packing Oil removal

Dust removalClean environment (Class 10 to 1,000) Battery assembly process LCD-related post assembly process In-vehicle camera assembly process SHD-□□ Electrolytic polishing + precision cleaning Degassing double packing Oil removal

Dust removal

Outgas reductionVacuum environment

Clean environment (Class 10 to 1,000)Pre-semiconductor process Liquid crystal deposition process Pre-OLED process ■Notes

Cleaning also removes rust prevention oil, which may make the product more susceptible to rusting than an uncleaned product.

Please be careful about the application location and storage environment.Outer diameter is configurable from 0.5 to 5 mm in 0.5 mm increments. The "Outer diameter polished finish" is also appealing. [Material] SUS304

Outer Dia. D(Ø) Environmentally friendly Inner Dia. d(Ø) Characteristics/Applications Material Finishing Method Manufacturing Method Overall Length L(mm) Surface Treatment Thickness t Threading Female Thread [M] Male Thread [M] Cleaning Method 0.5 ~ 5 RoHS Compliant (10 Substances) 0.34 ~ 4.6 Clean Washed Stainless Steel Polishing (1.6µm) Seamless 10 ~ 200 Not Provided 0.08 ~ 0.2 N/A - - Degreasing / Precision Cleaning Days to Ship: 14 Day(s) or more  14 Day(s) or more

14 Day(s) or more

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Outer Dia. D(Ø) |

| Environmentally friendly |

| Inner Dia. d(Ø) |

| Characteristics/Applications |

| Material |

| Finishing Method |

| Manufacturing Method |

| Overall Length L(mm) |

| Surface Treatment |

| Thickness t |

| Threading |

| Female Thread [M] |

| Male Thread [M] |

| Cleaning Method |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| Brand | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI |

| Product Series | Thin-Walled Ground Stainless Steel Hollow Tubes - Precision I.D. / O.D. | Thick-Walled Ground Stainless Steel Hollow Tubes - Straight Type | Thick-Walled Ground Stainless Steel Hollow Tubes - One End Threaded or Both Ends Threaded | [Clean & Pack]Thick-Walled Ground Stainless Steel Hollow Tubes | [Clean & Pack]Thin-Walled Ground Stainless Steel Hollow Tubes | [Clean & Pack]Thick-Walled Ground Stainless Steel Hollow Tubes - One End and Both Ends Threaded | [Clean & Pack]Thick-Walled Ground Stainless Steel Hollow Tubes - Precision I.D./O.D. | |

| CAD |

|

|

|

|

|

|

|

|

| From | ||||||||

| Days to Ship | 8 Day(s) or more | 10 Day(s) or more | 7 Day(s) or more | 8 Day(s) or more | 12 Day(s) or more | 12 Day(s) or more | 12 Day(s) or more | 14 Day(s) or more |

| Outer Dia. D(Ø) | 2 ~ 30 | 0.5 ~ 5 | 6 ~ 50 | 8 ~ 30 | 6 ~ 50 | 2 ~ 30 | 8 ~ 30 | 0.5 ~ 5 |

| Environmentally friendly | - | - | - | - | RoHS Compliant (10 Substances) | RoHS Compliant (10 Substances) | RoHS Compliant (10 Substances) | RoHS Compliant (10 Substances) |

| Inner Dia. d(Ø) | 1 ~ 29 | - | 3 ~ 35 | - | 3 ~ 35 | 1 ~ 29 | 4 ~ 16 | 0.34 ~ 4.6 |

| Characteristics/Applications | - | - | - | - | Clean Washed | Clean Washed | Clean Washed | Clean Washed |

| Material | SUS304 ~ SUS304 (Annealed Material) | SUS304 | SUS304 | SUS304 | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel |

| Finishing Method | Polishing (1.6µm) | Polishing (1.6µm) | Polishing (1.6µm) | Polishing (1.6µm) | Polishing (1.6µm) | Polishing (1.6µm) | Polishing (1.6µm) | Polishing (1.6µm) |

| Manufacturing Method | Weld-On | Seamless | Seamless | Seamless | Seamless | Weld-On | Seamless | Seamless |

| Overall Length L(mm) | - | - | - | - | 10 ~ 800 | 10 ~ 800 | 50 ~ 800 | 10 ~ 200 |

| Surface Treatment | - | - | - | - | Not Provided | Not Provided | Not Provided | Not Provided |

| Thickness t | - | - | - | - | 1.5 ~ 8 | 0.3 ~ 1 | 2 ~ 7 | 0.08 ~ 0.2 |

| Threading | - | - | - | - | N/A | N/A | One-End Male Thread / Male Threads on Both Ends | N/A |

| Female Thread [M] | - | - | - | - | - | - | - | - |

| Male Thread [M] | - | - | - | - | - | - | 8 / 10 / 12 / 16 / 20 / 24 / 30 | - |

| Cleaning Method | - | - | - | - | Degreasing / Precision Cleaning | Degreasing / Precision Cleaning | Degreasing / Precision Cleaning | Degreasing / Precision Cleaning |

Loading...

Configure

Specification/Dimensions

-

Outer Dia. D(Ø)

-

Environmentally friendly

-

Inner Dia. d(Ø)

-

Characteristics/Applications

-

Material

-

Finishing Method

- Drawn

- Polishing (1.6µm)

-

Manufacturing Method

- Seamless

- Weld-On

-

Overall Length L(mm)

-

Surface Treatment

- Not Provided

- Black Oxide

- Electroless Nickel Plating

-

Thickness t

-

Threading

-

N/A

-

One-End Female Thread

-

Female Threads on Both Ends

-

One-End Male Thread

-

Male Threads on Both Ends

-

N/A

-

Female Thread [M]

-

Male Thread [M]

- 8

- 10

- 12

- 16

- 20

- 24

- 30

-

Cleaning Method

- Degreasing

- Precision Cleaning

![[Clean & Pack]Thick-Walled Ground Stainless Steel Hollow Tubes](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/v1/p/jp/product/series/110310743489/110310743489_001_20230911105917.jpg?$product_view_b$)

![[Clean & Pack]Thin-Walled Ground Stainless Steel Hollow Tubes](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/v1/p/jp/product/series/110310744839/110310744839_001_20230911105917.jpg?$product_view_b$)

![[Clean & Pack]Thick-Walled Ground Stainless Steel Hollow Tubes - One End and Both Ends Threaded](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/v1/p/jp/product/series/110310743579/110310743579_001_20230911105917.jpg?$product_view_b$)

![[Clean & Pack]Thick-Walled Ground Stainless Steel Hollow Tubes - Precision I.D./O.D.](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/v1/p/jp/product/series/110310743939/110310743939_001_20230911105917.jpg?$product_view_b$)

![[Clean & Pack]Thick-Walled Ground Stainless Steel Hollow Tubes](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_c/v1/p/jp/product/series/110310743489/110310743489_001_20230911105917.jpg?$product_view_c$)

![[Clean & Pack]Thin-Walled Ground Stainless Steel Hollow Tubes](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_c/v1/p/jp/product/series/110310744839/110310744839_001_20230911105917.jpg?$product_view_c$)

![[Clean & Pack]Thick-Walled Ground Stainless Steel Hollow Tubes - One End and Both Ends Threaded](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_c/v1/p/jp/product/series/110310743579/110310743579_001_20230911105917.jpg?$product_view_c$)

![[Clean & Pack]Thick-Walled Ground Stainless Steel Hollow Tubes - Precision I.D./O.D.](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_c/v1/p/jp/product/series/110310743939/110310743939_001_20230911105917.jpg?$product_view_c$)

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy