(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 6:30 24/11/2024 to 4:30 (IST) 25/11/2024. We apologize for the inconvenience.

- Please note that the MISUMI Pune office and warehouse will be closed on November 20th due to the state election.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

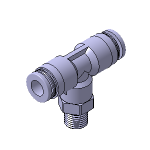

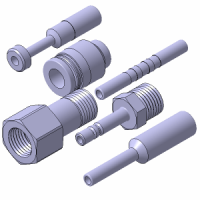

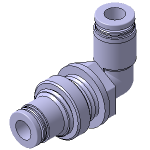

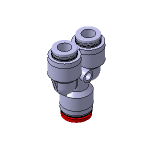

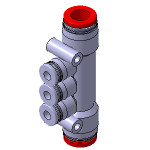

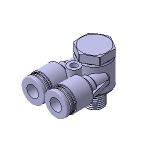

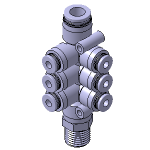

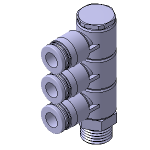

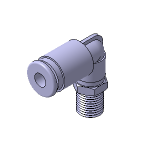

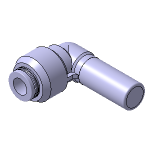

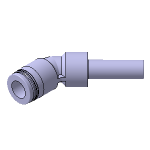

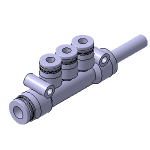

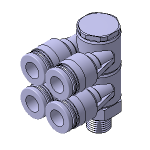

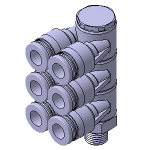

One-Touch Fitting(Branch A:Triple Branch A)

Brand |

|

|---|---|

| CAD |

|

| Days to Ship |

|

1 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

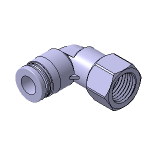

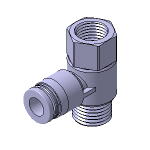

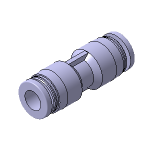

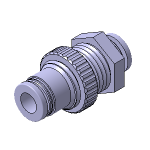

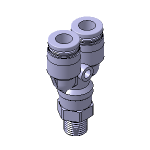

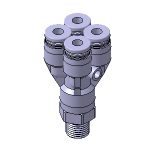

For General Piping, Tube Fitting, Triple Branch A

PISCO

A complete line of quick connect fittings.

[Features]

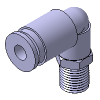

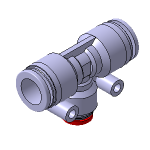

· Quick-connect fitting for general pneumatic piping.

· After installation, you can change the take-off angle of the resin main body. (applicable to some products)

· Allows centralized piping.

· Light gray specifications and cleanroom packaging specifications are also available as options.

· The cleanroom packaging specification uses fluorine-based grease.

· The product is washed with clean air and then packaged in a cleanroom (ISO class 6 equivalent).

[Applications]

· The standard specifications enable the use of water and are ideal for temperature control of molds and dies.

· After installation, you can change the take-off angle of the resin body. (applicable to some products)Fitting Type Applicable Fluid Screw Mounting, Direction Body Material Types Elbows Union, Equal Dia. Thread Material Union, Unequal Dia. Screw Mounting, Multipoint Application Seal Material For Swivel Parts, Rotary Equipment Parts Sockets, Reducers Other Shapes Branch A Applicable Tube O.D.1(φ) Applicable Tube Outer Diameter 2(φ) Screw Mounting, Multipoint Water / Air - - One-Touch Couplings - - - - Branch A Standard, Mini / Clean Environment - - - - Triple Branch A 4 ~ 12 - From: ₹ 900.65 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Fitting Type |

| Applicable Fluid |

| Screw Mounting, Direction |

| Body Material |

| Types |

| Elbows |

| Union, Equal Dia. |

| Thread Material |

| Union, Unequal Dia. |

| Screw Mounting, Multipoint |

| Application |

| Seal Material |

| For Swivel Parts, Rotary Equipment Parts |

| Sockets, Reducers |

| Other Shapes |

| Branch A |

| Applicable Tube O.D.1(φ) |

| Applicable Tube Outer Diameter 2(φ) |

You can add up to 6 items per a category to the compare list. | |

| Brand | PISCO |

| Product Series | |

| CAD |

|

| From | ₹ 900.65 |

| Days to Ship | 5 Day(s) or more |

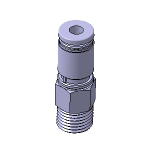

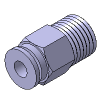

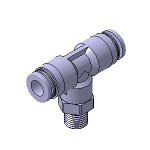

| Fitting Type | Screw Mounting, Multipoint |

| Applicable Fluid | Water / Air |

| Screw Mounting, Direction | - |

| Body Material | - |

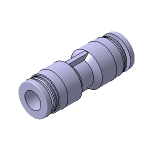

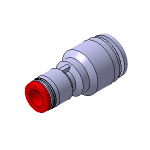

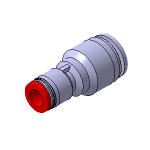

| Types | One-Touch Couplings |

| Elbows | - |

| Union, Equal Dia. | - |

| Thread Material | - |

| Union, Unequal Dia. | - |

| Screw Mounting, Multipoint | Branch A |

| Application | Standard, Mini / Clean Environment |

| Seal Material | - |

| For Swivel Parts, Rotary Equipment Parts | - |

| Sockets, Reducers | - |

| Other Shapes | - |

| Branch A | Triple Branch A |

| Applicable Tube O.D.1(φ) | 4 ~ 12 |

| Applicable Tube Outer Diameter 2(φ) | - |

Loading...

Configure

Specification/Dimensions

-

Fitting Type

-

Applicable Fluid

- Water

- Air

- Chemical, Solvent

- Mixed Gas

- Oil

-

Screw Mounting, Direction

-

Body Material

-

Types

- One-Touch Couplings

- One-Touch Coupling Related Components

-

Elbows

-

Union, Equal Dia.

-

Thread Material

-

Union, Unequal Dia.

-

Screw Mounting, Multipoint

-

Application

- Standard, Mini

- Clean Environment

- Food, Pharmaceutical Related

- Static Dissipation Antistatic

- Sputtering Resistant

- Mold Temperature Adjustment

- Heat Resistant

- Cold Resistant

-

Seal Material

-

For Swivel Parts, Rotary Equipment Parts

-

Sockets, Reducers

-

Other Shapes

-

Branch A

-

Applicable Tube O.D.1(φ)

Applicable Tube O.D.1>2>3

-

Applicable Tube Outer Diameter 2(φ)

Applicable Tube O.D.1>2>3

Related Categories to One-Touch Fitting

FAQ One-Touch Fitting

- Question: Why are they called "one-touch" Fitting?

- Answer: "One-touch" fittings, often referred to as "push-to-connect" fittings or "quick-connect" fittings, are called so because they are designed for easy and quick installation. The name "one-touch" reflects the simplicity of the fitting process – you can connect tubing or pipes to these fittings with just one simple action, typically pushing the tubing or pipe into the fitting until it locks in place. There's no need for additional tools, clamps, or complicated procedures.

- Question: How do one-touch fitting ensure a secure connection?

- Answer: One-touch fittings ensure a secure connection through a combination of design features. These features typically include:

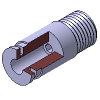

1.Push-to-Connect Mechanism: One-touch fittings have a mechanism that allows you to push the tubing into the coupling. This mechanism engages internal components to create a secure seal and connection.

2.Locking Mechanism: Inside the fittings, there are components that lock the tubing in place once it's pushed in. This prevents accidental disconnections due to vibrations or movement.

3.O-Rings or Seals: One-touch fittings often incorporate O-rings or other sealing mechanisms. These seals prevent air leakage and ensure that the connection remains airtight.

4.Release Ring: When you want to disconnect just pushing this ring, you disengage the locking mechanism, allowing you to easily remove the tubing. - Question: What types of tube fittings are available?

- Answer: There are various types of tube fittings, including compression fittings, push-to-connect fittings, flare fittings, quick-connect fittings, and threaded fittings. Each type is designed for specific applications and offers unique advantages in terms of ease of installation, reliability, and performance.

- Question: What factors should I consider when choosing a tube fitting?

- Answer: Tubing material and size: Fittings are designed for specific tubing materials (e.g., nylon, stainless steel) and sizes (usually based on outside diameter).

Pressure and temperature rating: Choose a fitting that can handle the maximum pressure and temperature of your system.

Application: Different applications may require specific fitting functions (e.g., elbows for turns, tees for branching).

Ease of use: Consider how easy it is to assemble and disassemble the fitting for your needs. - Question: Why are fitting so crucial in machinery operations?

- Answer: Pneumatic fitting are essential in machinery because they facilitate quick and dependable connections between pneumatic components, enabling efficient operation, easy maintenance, and flexible system adjustments.

- Question: What are the major types of fitting?

- Answer: The Air fitting has various shapes and materials but can be divided into 2 major types:

1. ‘The quick connect fitting’ is 2 pieces connector. A ‘Female quick connect fitting’ is connected to the machine to receive or deliver air. And another one is the ‘Male quick connect fitting’ which is used to join the female quick connect fitting and the air hose. by using the tube that has a raceway at the end to lock with the locking ball inside the female quick connect fitting.

2. ‘One-Touch Fitting’ is the type of Fitting that is used to connect an air hose to another one to make it longer, reduce the size of the air hose or separate it from other machines. - Question: What is the significance of synthetic rubber in flexible fitting?

- Answer: When compared to other fluids, Air has a small molecule that makes it able to leak out of the pneumatic system. Even a very small gap. So, the synthetic rubber inside the flexible fittings is used to seal those gaps to prevent air leakage. And make the pneumatic system work efficiently.

- Question: Can fitting impact energy efficiency?

- Answer: Of course, But in order to do that, the choosing of One-touch fittings is important. Because the proper fitting can help prevent air leakage. So the pneumatic system will be able to work efficiently. It also helps to reduce the workload of the air compressor pump as it relates to electricity consumption.

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy