(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Please note that the MISUMI Pune office and warehouse will be closed on November 20th due to the state election.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

Rollers(Material:Urethane)

|

Mounting Method

|

|

|---|---|

Brand |

|

| CAD |

|

| Days to Ship |

|

2 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

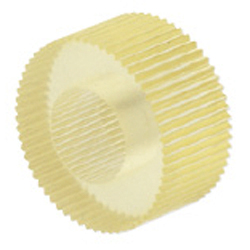

Urethane Rollers - with Pressed Bearings

MISUMI

This is a urethane roller with bearings glued to the urethane roller.

Since no core metal is used, it can be purchased at a low price.

[Type] Urethane roller

[Roller shape] Straight

[Urethane rubber processing] Adhesive

[Roller end specifications] With bearing

[Material] Bearing: Steel

> Urethane: Ether polyurethane (natural color)

[Hardness (shore)] A90

[Surface treatment] None- Volume Discount

Mounting Method O.D.(mm) Roller Type Material Roller Shape Inner Dia. d(mm) Length(mm) Urethane Rubber Processing With Bearings 20 ~ 50 Urethane/Rubber Roller Urethane Straight - ~50 / ~100 Adhesive From: ₹ 1,056.83 Days to Ship: Same day or more  Same day or more

Same day or more

-

You can add up to 6 items per a category to the compare list.

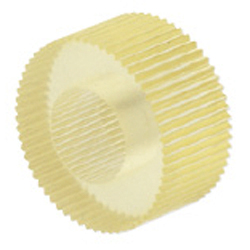

Urethane Rollers - Knurled Type

MISUMI

Urethane Rollers knurled to help grasp workpieces securely.

Mounting Method O.D.(mm) Roller Type Material Roller Shape Inner Dia. d(mm) Length(mm) Urethane Rubber Processing Straight 15 ~ 30 Urethane/Rubber Roller Urethane Knurled 8 ~ 15 ~50 No Machining Days to Ship: 7 Day(s) or more  7 Day(s) or more

7 Day(s) or more

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Mounting Method |

| O.D.(mm) |

| Roller Type |

| Material |

| Roller Shape |

| Inner Dia. d(mm) |

| Length(mm) |

| Urethane Rubber Processing |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| Brand | MISUMI | MISUMI |

| Product Series | ||

| CAD |

|

|

| From | ₹ 1,056.83 | |

| Days to Ship | Same day or more | 7 Day(s) or more |

| Mounting Method | With Bearings | Straight |

| O.D.(mm) | 20 ~ 50 | 15 ~ 30 |

| Roller Type | Urethane/Rubber Roller | Urethane/Rubber Roller |

| Material | Urethane | Urethane |

| Roller Shape | Straight | Knurled |

| Inner Dia. d(mm) | - | 8 ~ 15 |

| Length(mm) | ~50 / ~100 | ~50 |

| Urethane Rubber Processing | Adhesive | No Machining |

Loading...

Configure

Specification/Dimensions

-

O.D.(mm)

-

Roller Type

- Urethane/Rubber Roller

- Metal Roller

- Plastic Roller

- Adjusting Components

-

Material

- Steel

- Aluminum

- Stainless Steel

- Urethane

- Plastic

-

Roller Shape

-

Straight

Straight -

Crowned

Crowned -

Groove

Groove -

Knurled

Knurled

-

-

Inner Dia. d(mm)

-

Length(mm)

- ~50

- ~100

- ~300

- ~500

- ~1000

-

Urethane Rubber Processing

Related Categories to Rollers

FAQ Rollers

- Question: What are conveyor rollers?

- Answer: Conveyor rollers are cylindrical components that allow materials to move smoothly along a conveyor system. They reduce friction and facilitate the movement of items on the conveyor belt or system.

- Question: What are the different types of conveyor rollers?

- Answer: There are several types of conveyor rollers, including: • Straight rollers: Used for straight conveyor sections. • Return rollers: Used on the bottom side of the conveyor belt to support it as it returns to the head pulley. • Idlers: Used in combination with rollers to support the conveyor belt and provide tension. • Gravity rollers: Used in non-powered conveyor systems, rely on gravity for movement. • Motorized rollers: Contain an internal motor to drive conveyor movement. • Driven rollers: Powered by external motors and belts. • Tapered rollers: Used for curves in conveyor systems to help with directional changes.

- Question: What is the purpose of conveyor rollers in material handling?

- Answer: Conveyor rollers facilitate the movement of products, packages, or materials from one place to another. They are used in manufacturing, distribution, and packaging industries to reduce manual labor, increase efficiency, and streamline processes.

- Question: How do I choose the right conveyor rollers for my system?

- Answer: To choose the right rollers, consider: • The type of material or product being conveyed. • The load capacity required. • The speed at which the conveyor will operate. • The operating environment (e.g., temperature, humidity, and chemical exposure). • The type of conveyor system (gravity, powered, etc.).

- Question: How do you maintain conveyor rollers?

- Answer: Proper maintenance includes: • Regular cleaning to prevent dirt and debris buildup. • Checking and lubricating bearings to ensure smooth movement. • Inspecting rollers for wear, damage, or misalignment. • Replacing worn-out rollers to avoid disruptions in the system.

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy