(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

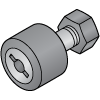

Cam Followers, Roller Followers(Cam Follower Stud Screw (Coarse):M30)

Cam Followers and Roller Followers, essential components for machine in factory automation. These precision bearings, operating on a rolling contact mechanism, are specifically designed to track the contours of cams or tracks, ensuring smooth and reliable motion. Our product range includes various types, such as stud type, yoke type, and cam followers with eccentric studs, each tailored to different mounting requirements and precise positioning needs.

Crafted from durable materials, our Cam Followers and Roller Followers exhibit excellent performance even in harsh industrial environments while being easy to install and maintain, saving valuable time during assembly. Their robust construction ensures exceptional durability and long service life, reducing downtime and enhancing overall productivity in your automation projects.

With a high load-carrying capacity, they efficiently support heavy machinery, minimizing wear and stress on individual points, resulting in reliable and smooth motion control. Our followers find versatile applications in conveyor systems, robotics, CNC machines, packaging lines, and textile machinery, enabling precise positioning and controlled movements, enhancing the efficiency and accuracy of your automated systems.

Crafted from durable materials, our Cam Followers and Roller Followers exhibit excellent performance even in harsh industrial environments while being easy to install and maintain, saving valuable time during assembly. Their robust construction ensures exceptional durability and long service life, reducing downtime and enhancing overall productivity in your automation projects.

With a high load-carrying capacity, they efficiently support heavy machinery, minimizing wear and stress on individual points, resulting in reliable and smooth motion control. Our followers find versatile applications in conveyor systems, robotics, CNC machines, packaging lines, and textile machinery, enabling precise positioning and controlled movements, enhancing the efficiency and accuracy of your automated systems.

|

Product Category

|

|

|---|---|

Brand |

|

| CAD |

|

| Days to Ship |

|

1 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

INA

Cam follower.

[Features]

· Hex socket head with head and stud

· Grease sealed at deliveryRoller Outer Dia. D(Ø) Product Category Roller Width B(mm) Roller Type Tightening Method Cam Follower Stud Screw (Coarse)(mm) Roller Follower Inner Dia. D(mm) Cam Follower Type Material Size Standards Roller Follower Type 1 Roller Lining Shaft Roller Guiding Method Inner Ring Cam Follower: Stud Screw (Fine Thread)(mm) 80 Cam Follower 35 Spherical Outer Ring Hex Socket on Head Thread M30 - Standard Carbon Steel Metric System - - Provided With Retainer - - From: ₹ 8,173.99 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

| Brand |

|---|

| Product Series |

| From |

| Days to Ship |

| Roller Outer Dia. D(Ø) |

| Product Category |

| Roller Width B(mm) |

| Roller Type |

| Tightening Method |

| Cam Follower Stud Screw (Coarse)(mm) |

| Roller Follower Inner Dia. D(mm) |

| Cam Follower Type |

| Material |

| Size Standards |

| Roller Follower Type 1 |

| Roller Lining |

| Shaft |

| Roller Guiding Method |

| Inner Ring |

| Cam Follower: Stud Screw (Fine Thread)(mm) |

You can add up to 6 items per a category to the compare list. | |

| Brand | INA |

| Product Series | |

| From | ₹ 8,173.99 |

| Days to Ship | 5 Day(s) or more |

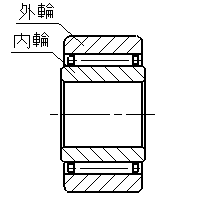

| Roller Outer Dia. D(Ø) | 80 |

| Product Category | Cam Follower |

| Roller Width B(mm) | 35 |

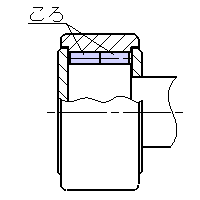

| Roller Type | Spherical Outer Ring |

| Tightening Method | Hex Socket on Head Thread |

| Cam Follower Stud Screw (Coarse)(mm) | M30 |

| Roller Follower Inner Dia. D(mm) | - |

| Cam Follower Type | Standard |

| Material | Carbon Steel |

| Size Standards | Metric System |

| Roller Follower Type 1 | - |

| Roller Lining | - |

| Shaft | Provided |

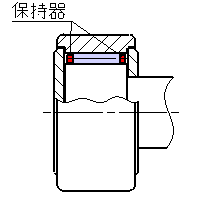

| Roller Guiding Method | With Retainer |

| Inner Ring | - |

| Cam Follower: Stud Screw (Fine Thread)(mm) | - |

Loading...

Configure

Specification/Dimensions

-

Roller Outer Dia. D(Ø)

-

Roller Width B(mm)

-

Roller Type

-

Tightening Method

-

Hex Socket on Head

Hex Socket on Head -

Hex Socket on Head Thread

Hex Socket on Head Thread -

Straight Slot

Straight Slot

-

-

Cam Follower Stud Screw (Coarse)(mm)

-

Roller Follower Inner Dia. D(mm)

-

Cam Follower Type

-

Material

- Carbon Steel

- Stainless Steel

-

Size Standards

- Metric System

- Imperial

-

Roller Follower Type 1

-

Roller Lining

- Not Provided

- Plastic

- Urethane

-

Shaft

-

Roller Guiding Method

-

Inner Ring

-

Cam Follower: Stud Screw (Fine Thread)(mm)

Related Categories to Cam Followers, Roller Followers

FAQ Roller Followers

- Question: What are the different types of Roller Followers?

- Answer: There are mainly three types of Roller Followers:

1. Stud Type Roller Followers: These have a stud attached to the outer ring, making them easy to mount.

2. Yoke Type Roller Followers: These have a yoke on the outer ring, providing more stability and load capacity.

3. Cam Followers with Eccentric Stud: These have an eccentric stud, allowing for easy adjustment of the position. - Question: What's the difference between cam followers and roller followers, and which one should you choose?

- Answer: Cam followers: These have a built-in threaded stud or shaft that allows them to be directly screwed into a surface.

Use cam followers if you have a location to directly screw them into a surface and need a simple installation.

Roller followers: These require a separate shaft for mounting as they don't have a built-in one. They typically come with a bore designed to fit onto an existing shaft.

Use roller followers if you already have a shaft in your design and need more flexibility in shaft size selection. - Question: What industries commonly use Roller Followers?

- Answer: Roller followers are widely used in industries where motion control and precise positioning are essential. Some common industries include:

Factory Automation and Robotics: Roller followers play a vital role in automating processes, controlling robotic movements, and maintaining accuracy in various assembly and handling tasks.

Material Handling and Conveyors: Roller followers are used in conveyor systems to guide and control the movement of materials efficiently.

Packaging and Printing: Roller followers are utilized in packaging machines and printing equipment to ensure smooth and precise movements during the packaging and printing processes.

Semiconductor Manufacturing: The semiconductor industry relies on roller followers for precise movement and positioning in manufacturing equipment.

Automotive Assembly Lines: Roller followers are employed in automotive manufacturing for tasks such as part handling and robot positioning. - Question: How do I choose the right cam follower for my application?

- Answer: To choose the right cam follower, consider these factors:

Load Capacity: Determine the maximum load your application requires.

Type of Load: Check if it's primarily radial, axial, or a combination of both.

Cam Follower Type: Decide between stud type or yoke type based on your mounting needs.

Track Conditions: Consider the surface conditions where the cam follower will operate.

Speed and Temperature: Ensure the cam follower can handle the operating speed and temperature range. - Question: In what machines are cam follower used?

- Answer: Cam followers are utilized in a wide range of machines and equipment, including:

Conveyor Systems: Cam followers guide and support the movement of conveyor belts.

CNC Machines: They play a role in precise tool positioning and movement control in computer numerical control (CNC) machines.

Industrial Robots and AGVs: Cam followers enable accurate motion control in robotic arms and automated guided vehicles.

Printing and Packaging Machines: Cam followers ensure smooth and precise motion during printing and packaging processes.

Textile Machinery: Cam followers are used in textile machines for controlling yarn tension and guiding various components. - Question: How do Roller Followers work?

- Answer: Roller followers work by following the profile of a specially designed cam. The cam's shape dictates the motion of the roller follower. As the cam rotates, it imparts motion to the roller follower, causing its rollers to move smoothly along the cam's surface.

The motion can be either linear or rotary, depending on the cam's profile. Roller followers are designed to reduce friction and ensure smooth movement, making them ideal for applications that require precise positioning and can handle high loads effectively. Proper lubrication is essential to minimize wear and friction, ensuring reliable operation and extending the roller follower's lifespan. Overall, roller followers play a crucial role in providing motion control in various factory automation applications.

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy