(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 6:30 24/11/2024 to 4:30 (IST) 25/11/2024. We apologize for the inconvenience.

- Please note that the MISUMI Pune office and warehouse will be closed on November 20th due to the state election.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

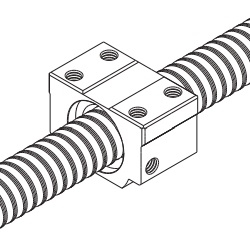

Ball Screw(Flange Shape:Block)

[What is a ball screw?] It is a part that utilizes the principle of linear motion rolling bearings to convert rotary motion to linear motion or vice versa, and is mainly used for positioning and transportation.

Brand |

|

|---|---|

| CAD |

|

| Days to Ship |

|

2 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

Rolled Ball Screw, Non-Preloading Square Nut Type BNT

THK

[Features]

· THK rolling ball screws are low-priced sending screws that modify the screw grinding shaft used in precision ball screws and use a new screw shaft created by combining high accuracy rolling pressing with special surface grinding finishing.

· Because all the ball rolling surfaces or the combined ball screw nuts have undergone grinding finishing, the gap in the shaft direction is smaller than conventional rolling ball screws, providing smooth operation.

· Also, an abundant standardized lineup is available so you can select the product that's optimal for your application.Screw Shaft O.D. d(Ø) Product Type Lead(mm) Accuracy Grade Flange Shape Axial End Type 14 ~ 32 Rolled Ball Screw 4 ~ 10 - Block - From: ₹ 16,733.66 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

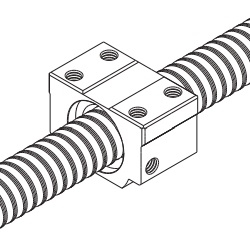

Rolled Ball Screws Block Nut - Shaft Dia. 15, 20, 25; Lead 5, 10 - Accuracy Grade C10

MISUMI

[Features]·Rolled ball screw that can be mounted directly on a table. ·The shaft diameter is ø15, 20, and 25.

Screw Shaft O.D. d(Ø) Product Type Lead(mm) Accuracy Grade Flange Shape Axial End Type 15 ~ 25 Rolled Ball Screw 5 ~ 10 C10 Block - Days to Ship: 8 Day(s) or more  8 Day(s) or more

8 Day(s) or more

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Screw Shaft O.D. d(Ø) |

| Product Type |

| Lead(mm) |

| Accuracy Grade |

| Flange Shape |

| Axial End Type |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| Brand | THK | MISUMI |

| Product Series | Rolled Ball Screws Block Nut - Shaft Dia. 15, 20, 25; Lead 5, 10 - Accuracy Grade C10 | |

| CAD |

|

|

| From | ₹ 16,733.66 | |

| Days to Ship | 5 Day(s) or more | 8 Day(s) or more |

| Screw Shaft O.D. d(Ø) | 14 ~ 32 | 15 ~ 25 |

| Product Type | Rolled Ball Screw | Rolled Ball Screw |

| Lead(mm) | 4 ~ 10 | 5 ~ 10 |

| Accuracy Grade | - | C10 |

| Flange Shape | Block | Block |

| Axial End Type | - | - |

Loading...

Configure

Specification/Dimensions

-

Screw Shaft O.D. d(Ø)

-

Product Type

-

Precision Ball Screw

Precision Ball Screw -

Rolled Ball Screw

Rolled Ball Screw -

Ball Screw Related Products

Ball Screw Related Products

-

-

Lead(mm)

-

Accuracy Grade

-

Flange Shape

-

Square Shape

Square Shape -

Round Shape

Round Shape -

Round Shape, 2 Set Screw Flats at both ends

Round Shape, 2 Set Screw Flats at both ends -

Block

Block -

Miniature

Miniature

-

-

Axial End Type

- Standard Shaft End Alterations Item

Related Categories to Ball Screw

FAQ Ball screw

- Question: What are the benefits of using a ball screw over a lead screw?

- Answer: Ball screws offer higher efficiency, precision, and speed compared to lead screws. Ball screw have lower friction and can transfer higher loads with greater accuracy and repeatability. They require less power to operate and have longer lifespans.

- Question: How do you choose the right ball screw for your application?

- Answer: To choose the right ball screw, you need to consider factors such as load capacity, speed, accuracy, and repeatability. You should also consider environmental conditions like temperature and humidity. It is recommended to consult with a ball screw supplier or engineer to ensure that the ball screw meets your application requirements.

- Question: How do you determine the load capacity of a ball screw?

- Answer: The load capacity of a ball screw depends on factors such as screw diameter, lead, and the number of ball circuits. You can calculate the load capacity using manufacturer-provided formulas or consult with a ball screw supplier or engineer to determine the load capacity for your specific application.

- Question: How do you lubricate a ball screw?

- Answer: Ball screws require lubrication to reduce friction and wear. The appropriate lubricant and lubrication method depends on the specific application and the type of ball screw. It is recommended to consult with the ball screw manufacturer or supplier to ensure that the right lubricant and lubrication method is used.

- Question: What are the maintenance requirements for ball screws?

- Answer: Maintenance requirements for ball screws include regular inspection for signs of wear or damage, cleaning, and lubrication. It is essential to follow the manufacturer's recommendations and guidelines for maintenance to ensure the proper functioning and longevity of the ball screw.

- Question: How many types of ball screws are there, and what are their differences?

- Answer: There are several types of ball screws, including ground ball screws, rolled ball screws, precision ball screws, miniature ball screws, and large-diameter ball screws. The main differences between these types of ball screws are in their manufacturing methods, accuracy, load capacity, and application suitability. Consult with a ball screw supplier or engineer to determine the right type of ball screw for your specific application.

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy