(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

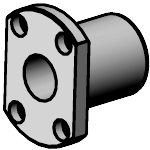

Linear Bushings(Types:Open)

|

Type

|

|

|---|---|

Brand |

|

| CAD |

|

| Days to Ship |

|

2 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

THK

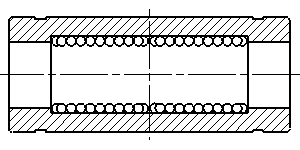

This linear bushing has an outer diameter formed by a highest-precision cylinder, and is used in a wide range of applications.

Part of the milli series, the most widely used series in Japan.Type Environmentally friendly Inscribed Circle Dia. dr(Ø) Characteristics/Applications Overall Length L(mm) Flange Type Style Outer Cylinder Material Outer Cylinder Surface Treatment Outer Dia. D(Ø) Lubrication Type Accuracy Ball Recirculating Type Motion Types Length Eccentricity(µm) Flange Shape Linear Motion / Rotational Motion Basic Rated Load, Dynamic Rating(N) Cleaning Method Straight - 13 ~ 40 - 32 ~ 80 - Open Type, Clearance Adjusting Type Steel No Surface Treatment 23 ~ 60 Not Provided High Grade Single Linear Open Standard 12 ~ 20 - - - - Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

![Linear Bushing Slit (Opening) Type [LKBMUUOP]](//in.misumi-ec.com/linked/material/mech/KBS1/PHOTO/LMUUOP.jpg?$product_view_b$)

Linear Bushing Slit (Opening) Type [LKBMUUOP]

KBS

Opening type Linear bushing with slit. Type with seal. Use with hardened shaft of g6 tolerance is recommended. Abundant variety of shaft diameters are available. Since its founding in 1995, the KBS Ltd. has steadily built a domestic following in China. The linear bushings, the company's leading products, top the market in China.

Type Environmentally friendly Inscribed Circle Dia. dr(Ø) Characteristics/Applications Overall Length L(mm) Flange Type Style Outer Cylinder Material Outer Cylinder Surface Treatment Outer Dia. D(Ø) Lubrication Type Accuracy Ball Recirculating Type Motion Types Length Eccentricity(µm) Flange Shape Linear Motion / Rotational Motion Basic Rated Load, Dynamic Rating(N) Cleaning Method Straight - 12 ~ 25 - 30 ~ 59 - Open Type, Clearance Adjusting Type Steel No Surface Treatment 21 ~ 40 Not Provided Standard Grade Single Linear Open Standard 12 ~ 15 - - - - Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Type |

| Environmentally friendly |

| Inscribed Circle Dia. dr(Ø) |

| Characteristics/Applications |

| Overall Length L(mm) |

| Flange Type |

| Style |

| Outer Cylinder Material |

| Outer Cylinder Surface Treatment |

| Outer Dia. D(Ø) |

| Lubrication Type |

| Accuracy |

| Ball Recirculating Type |

| Motion |

| Types |

| Length |

| Eccentricity(µm) |

| Flange Shape |

| Linear Motion / Rotational Motion |

| Basic Rated Load, Dynamic Rating(N) |

| Cleaning Method |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| Brand | THK | KBS |

| Product Series | ||

| CAD |

|

|

| From | ||

| Days to Ship | 5 Day(s) or more | 5 Day(s) or more |

| Type | Straight | Straight |

| Environmentally friendly | - | - |

| Inscribed Circle Dia. dr(Ø) | 13 ~ 40 | 12 ~ 25 |

| Characteristics/Applications | - | - |

| Overall Length L(mm) | 32 ~ 80 | 30 ~ 59 |

| Flange Type | - | - |

| Style | Open Type, Clearance Adjusting Type | Open Type, Clearance Adjusting Type |

| Outer Cylinder Material | Steel | Steel |

| Outer Cylinder Surface Treatment | No Surface Treatment | No Surface Treatment |

| Outer Dia. D(Ø) | 23 ~ 60 | 21 ~ 40 |

| Lubrication Type | Not Provided | Not Provided |

| Accuracy | High Grade | Standard Grade |

| Ball Recirculating Type | Single | Single |

| Motion | Linear | Linear |

| Types | Open | Open |

| Length | Standard | Standard |

| Eccentricity(µm) | 12 ~ 20 | 12 ~ 15 |

| Flange Shape | - | - |

| Linear Motion / Rotational Motion | - | - |

| Basic Rated Load, Dynamic Rating(N) | - | - |

| Cleaning Method | - | - |

Loading...

Configure

Specification/Dimensions

-

Environmentally friendly

-

Inscribed Circle Dia. dr(Ø)

-

Characteristics/Applications

-

Overall Length L(mm)

- 10

- 12

- 15

- 16

- 17

- 18

- 19

- 20

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 49

- 50

- 51

- 52

- 53

- 54

- 55

- 56

- 57

- 58

- 59

- 60

- 61

- 62

- 63

- 64

- 64.5

- 65

- 66

- 67

- 67.3

- 67.5

- 68

- 69

- 70

- 72

- 73

- 74

- 75

- 77

- 78

- 79

- 80

- 81

- 82

- 83

- 84

- 85

- 86

- 88

- 90

- 91

- 92

- 93

- 94

- 96

- 97

- 98

- 99

- 100

- 102

- 102.3

- 102.5

- 103

- 105

- 106

- 108

- 109

- 110

- 111

- 112

- 114

- 115

- 118

- 120

- 121

- 122

- 123

- 124

- 128

- 129

- 130

- 131

- 132

- 133

- 134

- 135

- 136

- 138

- 140

- 141

- 142

- 144

- 145

- 148

- 150

- 151

- 153

- 155

- 155.5

- 156

- 158

- 160

- 165

- 167

- 170

- 175

- 176

- 177

- 178

- 182

- 184

- 185

- 187

- 190

- 192

- 193

- 199

- 200

- 202

- 209

- 215

- 220

- 224

- 230

- 240

- 243

- 244

- 250

- 300

- 310

-

Flange Type

-

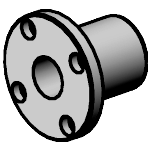

Standard Flange

Standard Flange -

Center Flanged

Center Flanged -

Male-Female Joint Flanged

Male-Female Joint Flanged

-

-

Style

-

Standard

Standard -

Open Type, Clearance Adjusting Type

Open Type, Clearance Adjusting Type

-

-

Outer Cylinder Material

- Steel

- Stainless Steel

- Aluminum

-

Outer Cylinder Surface Treatment

- No Surface Treatment

- Surface Treatment

-

Outer Dia. D(Ø)

-

Lubrication Type

- Not Provided

- Grease Coating

- With Lubrication Unit MX

-

Accuracy

-

Ball Recirculating Type

-

Motion

-

Types

-

Length

-

Eccentricity(µm)

-

Flange Shape

-

Round Flange

-

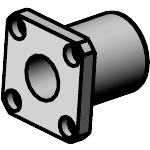

Square Flange

-

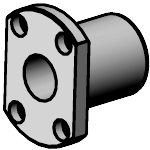

Compact Flange

-

Round Flange

-

Linear Motion / Rotational Motion

-

Linear Bushing (Linear Motion Only)

-

Linear Bushing (Linear Motion Only)

-

Basic Rated Load, Dynamic Rating(N)

-

Cleaning Method

- Degreasing

- Precision Cleaning

- Electrolytic Polishing + Precision Cleaning

Related Categories to Linear Bushings

-

- Linear Shafts

- Shaft Supports

- Shaft Collars

- Linear Bushings

- Ball Guides

- Spline Shaft

- Oil Free Bushings, Washers

- Oil Free Plates, Guide Rails

- Linear Guides

- Cable Carriers

- Ball Screw

- Support Units

- Lead Screws, Slide Screws

- Cross Roller

- Slide Packs, V Guides, Linear Rails

- Actuators

- Other Linear Motion Related Components

- Bellows

-

FAQ Linear Bushings

- Question: What is a linear bushing?

- Answer: A linear bushing is a bearing that supports linear motion. It is a cylindrical sleeve that fits around a shaft and provides a low-friction surface for the shaft to slide on. Linear bushings are used in a wide variety of applications, including machinery, automation, and robotics.

- Question: Why choose MISUMI linear bushings?

- Answer:

MISUMI is a leading supplier of linear bushings, offering a wide range of bushing types and sizes to meet the needs of a variety of applications. MISUMI linear bushings are known for their high quality, durability, and precision. These bushing are made by leading Asian manufacturers, and we carefully select them as per our customers' requirements.

High quality: These are made from high-quality materials and are manufactured to exacting standards.

Durability: These are designed to withstand harsh environments and heavy loads.

Precision: It can provide precise linear motion, which is essential for many applications.

Competitive prices: MISUMI linear bushings prices are competitively low as compared to market.

Excellent customer service: MISUMI offers excellent customer service, including technical support and assistance with product selection. - Question: What are the maintenance requirements for the MISUMI Linear bushings?

- Answer: MISUMI Linear bushings require periodic lubrication to maintain their performance and longevity. The frequency of lubrication will depend on the specific application, but it is generally recommended to lubricate the bushings every 6 months or every 1,000 kilometers.

- Question: What are the different types of linear bushings available?

- Answer: Linear bushings are used in various applications to provide smooth and precise linear motion. There are different types of linear bushings available, For examples:

1. Standard Linear Bushings: This linear bushings are common use in general-purpose in linear motion applications.

2. Closed Linear Bushings: These linear bushings have a sealed design for protection against contaminants.

3. Open Linear Bushings: These linear bushings do not have seals, suitable for easy maintenance and accessibility.

4. Adjustable Linear Bushings: These linear bushings allow for adjustable clearance or pre-load for fine-tuning.

5. Flanged Linear Bushings: Extended flange for added support and stability.

6.Self-Lubricating Linear Bushings: Require no external lubrication, maintenance-free operation. - Question: How does a linear bearing differ from a linear bushing?

- Answer: There are some examples of differences between Linear bearings and Linear bushings

1.Load Capacity

Linear bearings are often designed to handle higher loads compared to linear bushings. The presence of rolling elements in linear bearings distributes the load over a larger contact area, allowing them to support heavier loads.

2.Construction

-Linear bearings typically have a more complex construction, involving a carriage or housing and rolling elements like balls or rollers for example linear guide’s slide block

-Linear bushings have a simpler design, usually consisting of a cylindrical sleeve or some type of linear bushings have balls inside

3.Precision:

- Linear bearings are known for their high precision and accuracy, making them suitable for applications that require precise positioning and minimal play or backlash.

- Linear bushings can provide linear motion support but may have slightly lower precision compared to linear bearings.

4.Cost

- Linear bearings with their rolling elements and higher precision tend to be more expensive.

- Linear bushings are generally more cost-effective than linear bearings. - Question: What are some common linear bushings applications?

- Answer:

Linear bushings are used in a wide variety of applications, including:

Machinery: Linear bushings are used in a variety of machinery, such as CNC machines, injection molding machines, and packaging machines.

Automation: Linear bushings are used in a variety of automated systems, such as robotic arms and pick-and-place machines.

Robotics: Linear bushings are used in a variety of robots, such as industrial robots and service robots.

Other applications: Linear bushings are also used in a variety of other applications, such as medical devices, office equipment, and transportation equipment. - Question: How to choose the right linear bushing for my application?

- Answer:

When choosing a linear bushing for your application, it is important to consider the following factors:

Load capacity: The linear bushing must be able to support the load that will be placed on it.

Speed: The linear bushing must be able to operate at the speed required for your application.

Accuracy: The linear bushing must be able to provide the accuracy required for your application.

Environment: The linear bushing must be made from a material that is suitable for the environment in which it will be used. - Question: How to install a linear bushing?

- Answer:

The installation process for a linear bushing will vary depending on the specific type of bushing and the application. However, there are some general steps that can be followed:

Clean the shaft and the housing to remove any dirt or debris.

Apply a lubricant to the shaft.

Place the linear bushing on the shaft and align it with the housing.

Secure the linear bushing to the housing using the appropriate hardware. - Question: What is the life expectancy of a linear bushing?

- Answer: The life expectancy of a linear bushing depends on a number of factors, including the type of bushing, the load it is supporting, the speed it is operating at, and the environment in which it is used. In general, linear bushings have a life expectancy of 10,000 to 100,000 hours.

- Question: What material is used for linear bushings?

- Answer: Linear bushings are typically made from steel or stainless steel. Steel bushings are more affordable, but stainless steel bushings are more durable and resistant to corrosion. Other materials that may be used for linear bushings include aluminum, bronze, and plastic.

- Question: What is the difference between linear bushings and linear guides?

- Answer: Linear bushings and linear guides are both used to support linear motion. However, there are some key differences between the two. Linear bushings are typically smaller and less expensive than linear guides. Linear guides also offer higher load capacity and precision than linear bushings.

![Linear Bushing Slit (Opening) Type [LKBMUUOP]](http://in.misumi-ec.com/linked/material/mech/KBS1/PHOTO/LMUUOP.jpg?$product_view_b$)

![Linear Bushing Slit (Opening) Type [LKBMUUOP]](http://in.misumi-ec.com/linked/material/mech/KBS1/PHOTO/LMUUOP.jpg?$product_view_c$)

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy