(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 6:30 23/3 to 4:30 (IST) 24/3/2025. We apologize for the inconvenience.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

TRUSCO NAKAYAMA Urethane, Rubber, Sponge, Felt

TRUSCO NAKAYAMA offers Urethane, Rubber, Sponge, Felt products in the Materials category such as, Urethane, Rubber, Sponge, Felt - Sheets and many more products that are related to Urethane, Rubber, Sponge, Felt. A wide range of manufacturing materials and product components. TRUSCO NAKAYAMA products are available to order through MISUMI online 24 hours a day. Free shipping, no minimum order.

TRUSCO NAKAYAMA Urethane, Rubber, Sponge, Felt

FAQ about Urethane Rubber Sponge and Felts

- Question: What is the heat resistant temperature of the adhesive seal?

- Answer: Heat resistant temperature is 110 °C

- Question: Does Eptosealer have oil resistant properties?

- Answer: It is not oil resistant.

Please avoid using with oil. - Question: What is the heat resistant temperature of the Silicone Rubber?

- Answer: Approximately 200°C.

It will be hardened and become tattered if temperature exceed 200°C. - Question: Which type of Urethane is strong against water and alcohol?

- Answer: Urethane that is relatively strong against water and alcohol is Ether-based Urethane such as the AXFH series (Urethane Cushion - Free designation type)

However, please avoid using it in a soaked place, and wipe it off if it wet. - Question: Does Fluororubber seal have water resistant properties?

- Answer: No.

- Question: The Fluororubber purchased in the past has become conductive. Why is this happened?

- Answer: Conductivity may appear due to deterioration over time.

- Question: Which Rubber has high weather resistant?

- Answer: Fluororubber, Ethylene Rubber, and Silicone Rubber

- Question: What is non-staining rubber?

- Answer: It is a rubber that suppresses color transfer (staining) to another material that some of the components (oil, cross-linking agent) contained in rubber contact with.

- Question: What is "Acrylic Urethane rubber-based copolymer foam"?

- Answer: It is a foam material with intermediate performance between rubber and resin.

So it is a foam that contains characteristics of resin, such as weather resistance and durability. - Question: Between Ether-based Polyurethane and Ester-based Polyurethane, which is easier to be hydrolyzation?

- Answer: Ester-based Polyurethane. So, it is not recommended to use in wet environment.

Note: "Ester-based Polyurethane" is not easily to be hydrolyzation. - Question: What is difference between Shore A and Asker C hardness?

- Answer: Shore A is used to measure the hardness of rubber, meanwhile Asker C is used to measure the hardness of sponge

- Question: Which product is Open-cell sponge?

- Answer: The Polyurethane spongeOtherwise, they are closed-cell sponge.

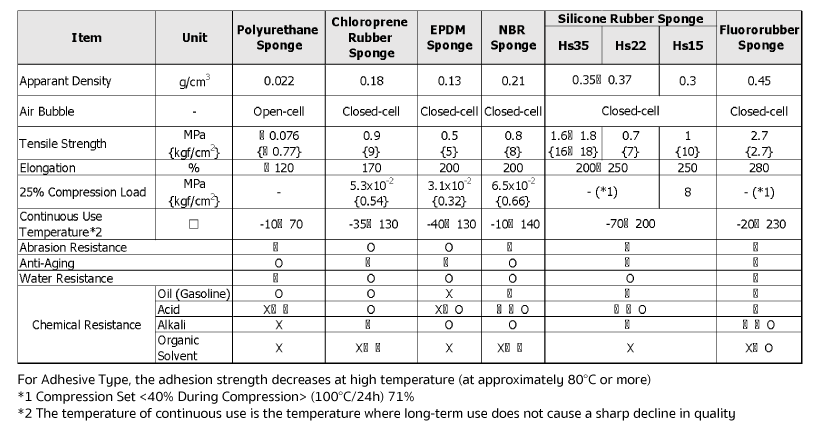

Please refer to the Characteristics of Sponges table as shown below:

• Characteristics of Sponges

- Question: I have purchased the Shores A90 and A70 Urethane, but the surface of A70 is rough. What is the difference in surface?

- Answer: The difference in surface is the surface cutting method.

Since A70 is softer than A90, the surface after cutting becomes rough. - Question: Do you offer the Semi-transparent silicone rubber?

- Answer: Semi-transparent silicone rubber is not available.

- Question: Can I cut the Fluororubber plate with 2mm thickness by cutter?

- Answer: For 2mm thickness plate, it can be cut with scissors or cutter.

- Question: Does lining process applicable for Vulkollan and Abrasion resistant type Urethane rubber?

- Answer: Vulkollan rubber is not available for lining process.

Abrasion resistant type Urethane is available for lining process. - Question: Please describe how to cut Urethane Silicone and Felts material.

- Answer: They can be cut by cutter or scissors.

However, it may be difficult depending on the hardness and thickness.

In that case, we recommend using a cutting machine.

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy