(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 4:30 2/3 to 3:30 (IST) 3/3/2025. We apologize for the inconvenience.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

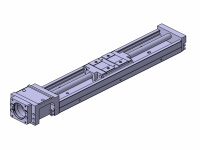

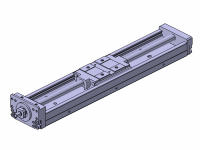

ORIENTAL MOTOR Linear Actuator (Steel body)

Brand |

|

|---|---|

| CAD |

|

| Days to Ship |

|

1 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

Rack and Pinion System, L Series

ORIENTAL MOTOR

The Rack and Pinion System L-Series enables compact, high-power linear transport.

The absolute system with hybrid control system AlphaStep AZ Series allows easy origin setting and origin return.Nominal (Height) Accuracy Lead(mm) Table Motor Mounting Orientation Main Body, Peripheral Components Cover With or w/o Motors Table Length L1(mm) Grease Ball Screw Shaft Dia.(Ø) With or w/o Lubricant Unit Table Width W1(mm) Amplifier Voltage With or w/o Retainer - - - - - Main Body - - - - - - - - - From: ₹ 81,368.80 Days to Ship: 18 Day(s) or more  18 Day(s) or more

18 Day(s) or more

| Brand |

|---|

| Product Series |

| From |

| Days to Ship |

| Nominal (Height) |

| Accuracy |

| Lead(mm) |

| Table |

| Motor Mounting Orientation |

| Main Body, Peripheral Components |

| Cover |

| With or w/o Motors |

| Table Length L1(mm) |

| Grease |

| Ball Screw Shaft Dia.(Ø) |

| With or w/o Lubricant Unit |

| Table Width W1(mm) |

| Amplifier Voltage |

| With or w/o Retainer |

You can add up to 6 items per a category to the compare list. | |

| Brand | ORIENTAL MOTOR |

| Product Series | |

| From | ₹ 81,368.80- |

| Days to Ship | 18 Day(s) or more |

| Nominal (Height) | - |

| Accuracy | - |

| Lead(mm) | - |

| Table | - |

| Motor Mounting Orientation | - |

| Main Body, Peripheral Components | Main Body |

| Cover | - |

| With or w/o Motors | - |

| Table Length L1(mm) | - |

| Grease | - |

| Ball Screw Shaft Dia.(Ø) | - |

| With or w/o Lubricant Unit | - |

| Table Width W1(mm) | - |

| Amplifier Voltage | - |

| With or w/o Retainer | - |

Loading...

Configure

Specification/Dimensions

-

Nominal (Height)

-

Accuracy

-

Lead(mm)

-

Table

-

Motor Mounting Orientation

-

Main Body, Peripheral Components

-

Cover

-

With or w/o Motors

-

Table Length L1(mm)

-

Grease

-

Ball Screw Shaft Dia.(Ø)

-

With or w/o Lubricant Unit

-

Table Width W1(mm)

-

Amplifier Voltage

-

With or w/o Retainer

Narrow search by specifying Manufacturer

Related Categories to Linear Actuator (Steel body)

FAQ Single Axis Actuators

- Question: What is a single axis actuator?

- Answer: A single axis actuator is a linear motion device that provides controlled movement along one axis. These actuators are commonly used in applications requiring precision positioning, such as robotics, automation, and industrial machinery.

- Question: What are the advantages of using Single Axis Actuators?

- Answer: There are several advantages to using Single-Axis Actuators:

High Precision: They offer precise and repeatable linear motion for accurate positioning tasks.

Compact Design: Their compact size allows for efficient use of space within your automation setup.

Versatility: They are available in various configurations and strokes to meet diverse application needs.

Robust Construction: MISUMI Single Axis Actuators are known for their durability and reliability in industrial environments.

Easy Integration: They offer straightforward installation and integration with other automation components.

- Question: What is the difference between ball screw and belt-driven Single Axis Actuators?

- Answer: • Ball Screw Actuators: Offer high load capacity, precision, and durability. They are ideal for heavy-duty applications requiring accurate positioning.

• Belt-Driven Actuators: Provide high-speed, smooth linear motion, and are often used in applications where cleanliness and low noise levels are critical.

- Question: What is the difference between a single axis actuator and a multi-axis system?

- Answer: A single axis actuator provides motion along one linear axis, while a multi-axis system combines multiple actuators to achieve motion along two or more axes (e.g., X, Y, and Z). Multi-axis systems are suitable for complex applications requiring coordinated motion.

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy