(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

NABEYA BI-TECH Knob Screws(Main Body Material:Steel)

Brand |

|

|---|---|

| CAD |

|

| Days to Ship |

|

7 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

NABEYA BI-TECH

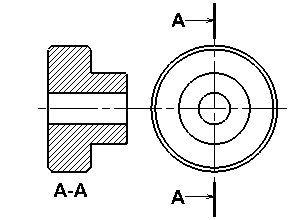

Knurled Knob_KNM/KNF

Knurled Knobs Screws are commonly used in various applications to secure, adjust, and control different mechanical devices. They offer a wide variety of sizes to choose from.

[Feature]

● Shape : Knurled Knobs

● Thread Size : M3, M4, M5, M6, M8 and M10

● Material :

KNM - SWCH10R

KNF - SUM22L

[Application]

Knurled Knob Screws are commonly used in fastening, assembly, adjustment, clamping and so onMounting Section Dia. d (mm) or Nominal Dia. Environmentally friendly Mounting Section Type Characteristics/Applications Mounting Section, Length L(mm) Main Body, Type Main Body Material Round Shape, Type Mounting Section, Material Threaded End Machining Set Screw Flat Machining Side Machined Polygonal Shape, Type T Shape, Type Additional Function Tapped, Round Hole Machining Main Body, Surface Treatment Mounting Section, Surface Treatment Cleaning Method M3 ~ M10 - Threaded / Tapped - 6 ~ 40 Round Shape Steel Cylindrical Shape Steel None - Knurling - - Not Provided Through Buff Polished + Chrome Plating Chrome Plating - From: ₹ 230.18 Days to Ship: Same day or more  Same day or more

Same day or more

-

You can add up to 6 items per a category to the compare list.

NABEYA BI-TECH

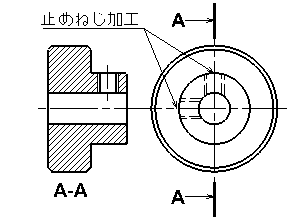

Clamp Knob KCF

Knob Screws are commonly used in various applications to secure, adjust, and control different mechanical devices. They offer a wide variety of sizes to choose from.

[Feature]

● Shape : Clamp Knob

● Thread Size : M5, M6, M8, M10 and M12

● Material : Steel S45C and Stainless Steel SUS303

[Application]

Clamp Knob Screws are commonly used in fastening, assembly, adjustment, clamping and so onMounting Section Dia. d (mm) or Nominal Dia. Environmentally friendly Mounting Section Type Characteristics/Applications Mounting Section, Length L(mm) Main Body, Type Main Body Material Round Shape, Type Mounting Section, Material Threaded End Machining Set Screw Flat Machining Side Machined Polygonal Shape, Type T Shape, Type Additional Function Tapped, Round Hole Machining Main Body, Surface Treatment Mounting Section, Surface Treatment Cleaning Method M5 ~ M12 - Tapped - 7 ~ 16 Round Shape Steel Clamp Shape Steel - - Knurling - - Not Provided Through Black Oxide Black Oxide - From: ₹ 267.62 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

NABEYA BI-TECH

Even long screws can be tightened quickly.

[Features]

· It can be tightened quickly, even with long screws.

· Please screw in the screw vertically straight into a hole and tighten it.

· If the tightening length (A) of the screw is shorter than the extension height (H), you can not achieve sufficient tightness.

· When designing, please ensure the screw tightening length (A) is not less than the total height (H) of the knobMounting Section Dia. d (mm) or Nominal Dia. Environmentally friendly Mounting Section Type Characteristics/Applications Mounting Section, Length L(mm) Main Body, Type Main Body Material Round Shape, Type Mounting Section, Material Threaded End Machining Set Screw Flat Machining Side Machined Polygonal Shape, Type T Shape, Type Additional Function Tapped, Round Hole Machining Main Body, Surface Treatment Mounting Section, Surface Treatment Cleaning Method M6 ~ M10 - Tapped - 14 ~ 20 Round Shape Steel Cylindrical Shape Steel - - Knurling - - Others Through Black Oxide Black Oxide - From: ₹ 1,369.85 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

NABEYA BI-TECH

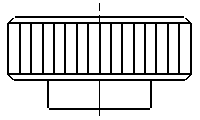

Hexagonal cast metal knob.

[Features]

·FC200, chrome-plated finish.

·KK: pilot hole, KKT: Female thread.

[Applications]

·When you want to install and remove screws without tools.Mounting Section Dia. d (mm) or Nominal Dia. Environmentally friendly Mounting Section Type Characteristics/Applications Mounting Section, Length L(mm) Main Body, Type Main Body Material Round Shape, Type Mounting Section, Material Threaded End Machining Set Screw Flat Machining Side Machined Polygonal Shape, Type T Shape, Type Additional Function Tapped, Round Hole Machining Main Body, Surface Treatment Mounting Section, Surface Treatment Cleaning Method 5 ~ M16 - Tapped / Others - 10 ~ 30 Polygonal Shape Steel - Steel - - - Hexagonal Shape - Not Provided Blind Bore Chrome Plating Chrome Plating - From: ₹ 920.11 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

NABEYA BI-TECH

Knurled Knob_KUM/KUF

Knurled Knobs Screws are commonly used in various applications to secure, adjust, and control different mechanical devices. They offer a wide variety of sizes to choose from.

[Feature]

● Shape : Knurled Knobs

● Thread Size : M3, M4, M5, M6, M8 and M10

● Material :

KUM - SWCH10R

KUF - SUM22L

[Application]

Knurled Knob Screws are commonly used in fastening, assembly, adjustment, clamping and so onMounting Section Dia. d (mm) or Nominal Dia. Environmentally friendly Mounting Section Type Characteristics/Applications Mounting Section, Length L(mm) Main Body, Type Main Body Material Round Shape, Type Mounting Section, Material Threaded End Machining Set Screw Flat Machining Side Machined Polygonal Shape, Type T Shape, Type Additional Function Tapped, Round Hole Machining Main Body, Surface Treatment Mounting Section, Surface Treatment Cleaning Method M3 ~ M10 - Threaded / Tapped - 3 ~ 40 Round Shape Steel Cylindrical Shape Steel None - Knurling - - Not Provided Through Buff Polished + Chrome Plating Chrome Plating - From: ₹ 219.09 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

NABEYA BI-TECH

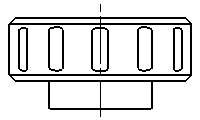

Steel cross knob.

[Features]

·FC200, chijimi baking paint.

·Pilot hole or female thread can be selected by product code.

·CK-prepared hole, CKT-female thread.

[Applications]

·When you want to install and remove screws without tools.Mounting Section Dia. d (mm) or Nominal Dia. Environmentally friendly Mounting Section Type Characteristics/Applications Mounting Section, Length L(mm) Main Body, Type Main Body Material Round Shape, Type Mounting Section, Material Threaded End Machining Set Screw Flat Machining Side Machined Polygonal Shape, Type T Shape, Type Additional Function Tapped, Round Hole Machining Main Body, Surface Treatment Mounting Section, Surface Treatment Cleaning Method 5 ~ M12 - Tapped / Others - 10 ~ 22 Polygonal Shape Steel - Steel - - - Cross Shape - Not Provided Blind Bore Coating None - From: ₹ 590.47 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

NABEYA BI-TECH

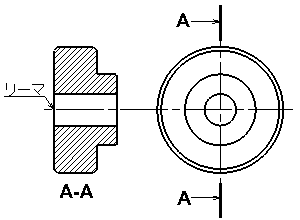

Positioning can be done at an angle of 6° or an integer multiple thereof.

[Features]

· LXY made of - A - steel.

· LXYS made of - A - stainless steel.

· Positioning can be done at an angle of 6° or its multiple, that is, 2, 3, 4, 5, 6, 10, 12, 15, 20, 30.

· It is an accurate and durable mechanism where the same results cannot be obtained by other methods, such as positioning the pin.Mounting Section Dia. d (mm) or Nominal Dia. Environmentally friendly Mounting Section Type Characteristics/Applications Mounting Section, Length L(mm) Main Body, Type Main Body Material Round Shape, Type Mounting Section, Material Threaded End Machining Set Screw Flat Machining Side Machined Polygonal Shape, Type T Shape, Type Additional Function Tapped, Round Hole Machining Main Body, Surface Treatment Mounting Section, Surface Treatment Cleaning Method M10 - Tapped - - Round Shape Steel Cylindrical Shape - - None Checker Knurled - - With Scale Blind Bore Black Oxide - - From: ₹ 13,350.55 Days to Ship: 8 Day(s) or more  8 Day(s) or more

8 Day(s) or more

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Mounting Section Dia. d (mm) or Nominal Dia. |

| Environmentally friendly |

| Mounting Section Type |

| Characteristics/Applications |

| Mounting Section, Length L(mm) |

| Main Body, Type |

| Main Body Material |

| Round Shape, Type |

| Mounting Section, Material |

| Threaded End Machining |

| Set Screw Flat Machining |

| Side Machined |

| Polygonal Shape, Type |

| T Shape, Type |

| Additional Function |

| Tapped, Round Hole Machining |

| Main Body, Surface Treatment |

| Mounting Section, Surface Treatment |

| Cleaning Method |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| Brand | NABEYA BI-TECH | NABEYA BI-TECH | NABEYA BI-TECH | NABEYA BI-TECH | NABEYA BI-TECH | NABEYA BI-TECH | NABEYA BI-TECH |

| Product Series | |||||||

| CAD |

|

|

|

|

|

|

|

| From | ₹ 230.18- | ₹ 267.62- | ₹ 1,369.85- | ₹ 920.11- | ₹ 219.09- | ₹ 590.47- | ₹ 13,350.55 |

| Days to Ship | Same day or more | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 8 Day(s) or more |

| Mounting Section Dia. d (mm) or Nominal Dia. | M3 ~ M10 | M5 ~ M12 | M6 ~ M10 | 5 ~ M16 | M3 ~ M10 | 5 ~ M12 | M10 |

| Environmentally friendly | - | - | - | - | - | - | - |

| Mounting Section Type | Threaded / Tapped | Tapped | Tapped | Tapped / Others | Threaded / Tapped | Tapped / Others | Tapped |

| Characteristics/Applications | - | - | - | - | - | - | - |

| Mounting Section, Length L(mm) | 6 ~ 40 | 7 ~ 16 | 14 ~ 20 | 10 ~ 30 | 3 ~ 40 | 10 ~ 22 | - |

| Main Body, Type | Round Shape | Round Shape | Round Shape | Polygonal Shape | Round Shape | Polygonal Shape | Round Shape |

| Main Body Material | Steel | Steel | Steel | Steel | Steel | Steel | Steel |

| Round Shape, Type | Cylindrical Shape | Clamp Shape | Cylindrical Shape | - | Cylindrical Shape | - | Cylindrical Shape |

| Mounting Section, Material | Steel | Steel | Steel | Steel | Steel | Steel | - |

| Threaded End Machining | None | - | - | - | None | - | - |

| Set Screw Flat Machining | - | - | - | - | - | - | None |

| Side Machined | Knurling | Knurling | Knurling | - | Knurling | - | Checker Knurled |

| Polygonal Shape, Type | - | - | - | Hexagonal Shape | - | Cross Shape | - |

| T Shape, Type | - | - | - | - | - | - | - |

| Additional Function | Not Provided | Not Provided | Others | Not Provided | Not Provided | Not Provided | With Scale |

| Tapped, Round Hole Machining | Through | Through | Through | Blind Bore | Through | Blind Bore | Blind Bore |

| Main Body, Surface Treatment | Buff Polished + Chrome Plating | Black Oxide | Black Oxide | Chrome Plating | Buff Polished + Chrome Plating | Coating | Black Oxide |

| Mounting Section, Surface Treatment | Chrome Plating | Black Oxide | Black Oxide | Chrome Plating | Chrome Plating | None | - |

| Cleaning Method | - | - | - | - | - | - | - |

Loading...

Configure

Specification/Dimensions

-

Mounting Section Dia. d (mm) or Nominal Dia.

-

Environmentally friendly

-

Mounting Section Type

- Threaded

- Threaded (Stepped)

- Tapped

- Tapped (Stepped)

- Round Bore

- Press Fit

- Others

-

Characteristics/Applications

-

Mounting Section, Length L(mm)

-

Main Body, Type

-

Main Body Material

- Stainless Steel

- Steel

- Aluminum

- Nylon

- Phenol

- ABS

- Polyacetal

- Brass

- Polyamide

- Polypropylene

- Melamine Plastic

- EPDM

- Others

- Vinyl

-

Round Shape, Type

-

Mounting Section, Material

-

Threaded End Machining

- None

- Spherical

- With Pad

- Cone Point

-

Set Screw Flat Machining

-

Side Machined

-

Polygonal Shape, Type

-

T Shape, Type

-

Additional Function

-

Tapped, Round Hole Machining

-

Main Body, Surface Treatment

-

Mounting Section, Surface Treatment

-

Cleaning Method

- Degreasing

- Precision Cleaning

- Electrolytic Polishing + Precision Cleaning

Narrow search by specifying Manufacturer

-

- MISUMI (9)

- MITSUBOSHI CI (11)

- NABEYA BI-TECH (7)

- KONISHI (5)

- DAIMARU BYORA SEISAKUSHO (4)

- IMAO CORPORATION (4)

- ESCO (2)

- TRUSCO NAKAYAMA (2)

- KYOWA (0)

- TAKIGEN (0)

- KONOE (0)

- GOSHO WORKS (0)

- RICHENGINEERING (0)

Related Categories to Knob Screws

FAQ Knob Screws

- Question: How do I properly install the knob screw?

- Answer: Here are some example to install a Knob Screws tapped type

1. Prepare the Surface: Clean and clear the area where the knob screw will be installed.

2. Choose the Right Screw: Select a screw with the appropriate size and thread that matches the knob.

3. Mark the Location: Use a pencil to mark where the knob screw will go, ensuring proper alignment.

4. Create Pilot Holes (if needed): Use a drill to create small guide holes in the marked spots, if the material is hard.

5. Insert the Screw: Place the screw through the knob and into the pilot hole or surface.

6. Tighten the Screw: Use a screwdriver to turn the screw clockwise, securely fastening the knob in place.

7. Test the Knob: Check the knob's movement and stability to ensure proper installation.

8. Adjust if Necessary: If the knob feels loose, you may need to tighten the screw further. - Question: Type of knobs screw?

- Answer: There are various types of knob screws designed for specific applications. Here are a few common types:

1. Round Knurled Thumb Screws: These have textured heads for better grip, often used in applications where a secure grip is essential.

2. Lobed Knobs: Have a lobed design for a comfortable grip, commonly found on industrial and mechanical equipment.

3. Ball Knobs: These have a spherical shape and are commonly used on levers or control mechanisms.

4. T-Knobs: Shaped like the letter "T," these knobs are simple to turn and are used in applications where frequent adjustments are needed.

5. Star Knobs: Featuring a star-shaped head for easy turning, often used in applications requiring frequent adjustments.

6. Mushroom Knobs: Shaped like a mushroom. It is used for cabinets, drawers, and doors, these knobs provide a comfortable grip for opening and closing

- Question: How to choose the knob screw?

- Answer: Here are some example how to choose the knob screw

1. Usage: Identify its purpose, such as indoor/outdoor and specific applications like machines, jig fixtures, doors, cabinets, etc.

2. Material: Match durability to the environment (stainless steel, aluminum, brass and plastic (eg., ABS, Nylon and so on).

3. Thread Type and Thread Size : Ensure screw matches knob (Threaded, Tapped) or Press fit. and the thread size is appropriate to install

4. Size: Select a knob head size that is appropriate for your intended use.

5. Head Type: Choose based on knob design (eg.,round, T Shape, Wing Shape, Polygon shape etc.).

6. Easy to install : Ensure easy installation and tightening.

7. Follow Guidelines: Check knob manufacturer's recommendations. - Question: What is the usage for knob screw?

- Answer: The primary usage of a knob screw is to enable manual control, adjustment, or fastening in a wide range of applications. Here are additional examples of how knob screws are used:

1. Camera Tripods: Knob screws are used to secure the legs and adjust the height of camera tripods, aiding photographers in achieving stable shots.

2. HVAC Systems: Knob screws are used to control airflow direction and intensity in ventilation systems, enhancing indoor air quality and comfort.

3. Scientific Research Instruments: In laboratories, knob screws are employed to fine-tune the position of laser optics, ensuring precise experimental setups.

4. Automated Manufacturing: Knob screws play a role in industrial automation by adjusting the position of sensors. - Question: What is the difference between knob screw and door knob?

- Answer: Knob Screw:

A knob screw is a type of fastener used to secure or adjust objects together. It consists of a threaded and a head. The head is designed for easy gripping and turning by hand. Knob screws are commonly used in applications where frequent adjustments or temporary fastening is required. They are often found in devices like clamps, jigs, and fixtures. The main purpose of a knob screw is to provide a manual way of securing two components together without the need for additional tools.

Door Knob:

A door knob, on the other hand, is a handle or knob attached to a door that allows people to open and close the door. It is usually mounted on a spindle that connects the knob on the outside of the door to a mechanism on the inside, allowing the door to be latched or unlatched. Door knobs come in various designs and materials, and they serve both functional and aesthetic purposes. They are an integral part of doors in buildings and structures

In summary,

A knob screw is a threaded fastener used for securing or adjusting objects together, often by hand.

A door knob is a handle attached to a door, allowing people to open and close the door, serving a functional and aesthetic purpose.

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy