(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

MISUMI Flat Belt Idlers(Shaft (Bore) Dia. d:8A)

Brand |

|

|---|---|

| CAD |

|

2 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

Idlers for Flat Belts-Straight Type/Crosspiece Groove Straight Type/Crowned Type/Width L110-500

MISUMI

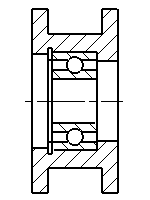

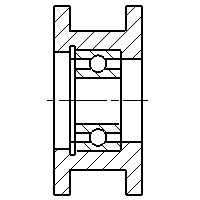

· Product type: Idlers.

· Idlers type: Bearing Built-in.

· Shape of Idlers: Straight type, Crosspiece Groove Straight Type and Crowned Type.

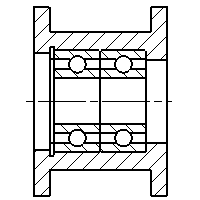

· Shaft Type : Bearing on Each End (2-Bearing in Total)

· The product code series Straight type: ROFAWC, ROFMWC and ROFSWC

· The product code series Crowned Type: ROFAWT, ROFMWT and ROFSWT

· The product code series Crosspiece Groove Straight: ROFAWM, ROFMWM and ROFSWM

· Outer Diameter: 30-80 mm.

· Shaft (Bore) Diameter: 8-35 mm.

· Length: 110-510 mm.

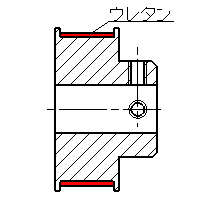

· Idler Engineering Plastic Roller, Steel Roller (TC-RP, TC-RU)Shape With or w/o Flange Outer Dia. D(Ø) Nominal Width T(mm) Length L(mm) Flange Shape Type Material Shaft Type Surface Urethane Shaft (Bore) Dia. d(mm) Surface Treatment Shaft Type Straight / Crowned No Flange 30 - ~300 / ~500 - Idlers (Bearing Built-in) Steel / Stainless Steel 1-Bearing on Each End (2-Bearing in Total) Urethane Not Provided 8A Not Provided / Electroless Nickel Plating - Days to Ship: 10 Day(s) or more  10 Day(s) or more

10 Day(s) or more

-

Economy series

You can add up to 6 items per a category to the compare list.

MiSUMi Economy

MiSUMi EconomyFlat Belts Idlers Width 110 - 500

MiSUMi EconomyMISUMI

Shape With or w/o Flange Outer Dia. D(Ø) Nominal Width T(mm) Length L(mm) Flange Shape Type Material Shaft Type Surface Urethane Shaft (Bore) Dia. d(mm) Surface Treatment Shaft Type Straight / Crowned No Flange 30 - ~300 / ~500 - Idlers (Bearing Built-in) Steel / Stainless Steel 1-Bearing on Each End (2-Bearing in Total) Urethane Not Provided 8A Not Provided / Electroless Nickel Plating - Days to Ship: 9 Day(s)  9 Day(s)

9 Day(s)

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Shape |

| With or w/o Flange |

| Outer Dia. D(Ø) |

| Nominal Width T(mm) |

| Length L(mm) |

| Flange Shape |

| Type |

| Material |

| Shaft Type |

| Surface Urethane |

| Shaft (Bore) Dia. d(mm) |

| Surface Treatment |

| Shaft Type |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| Brand | MISUMI | MISUMI |

| Product Series | Idlers for Flat Belts-Straight Type/Crosspiece Groove Straight Type/Crowned Type/Width L110-500 | |

| CAD |

| |

| From | - | - |

| Days to Ship | 10 Day(s) or more | 9 Day(s) |

| Shape | Straight / Crowned | Straight / Crowned |

| With or w/o Flange | No Flange | No Flange |

| Outer Dia. D(Ø) | 30 | 30 |

| Nominal Width T(mm) | - | - |

| Length L(mm) | ~300 / ~500 | ~300 / ~500 |

| Flange Shape | - | - |

| Type | Idlers (Bearing Built-in) | Idlers (Bearing Built-in) |

| Material | Steel / Stainless Steel | Steel / Stainless Steel |

| Shaft Type | 1-Bearing on Each End (2-Bearing in Total) | 1-Bearing on Each End (2-Bearing in Total) |

| Surface Urethane | Urethane Not Provided | Urethane Not Provided |

| Shaft (Bore) Dia. d(mm) | 8A | 8A |

| Surface Treatment | Not Provided / Electroless Nickel Plating | Not Provided / Electroless Nickel Plating |

| Shaft Type | - | - |

Loading...

Configure

Specification/Dimensions

-

Shape

-

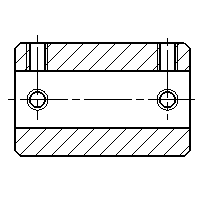

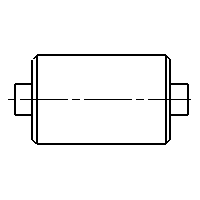

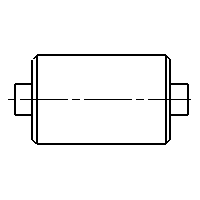

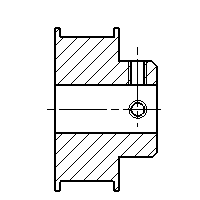

Straight

Straight -

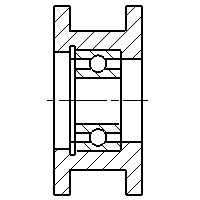

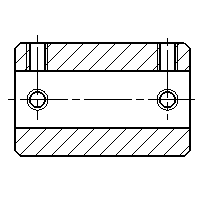

Crowned

Crowned -

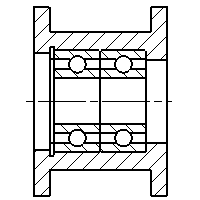

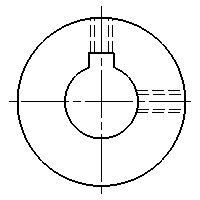

Crosspiece Groove Straight

Crosspiece Groove Straight

-

-

With or w/o Flange

-

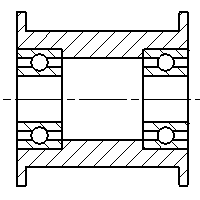

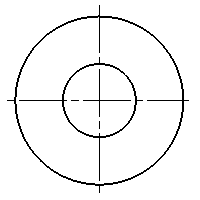

Flange

Flange -

No Flange

No Flange

-

-

Outer Dia. D(Ø)

-

Nominal Width T(mm)

-

Length L(mm)

- ~50

- ~100

- ~300

- ~500

-

Flange Shape

-

Type

- Idlers (Bearing Built-in)

- Pulleys

-

Material

- Steel

- Aluminum

- Stainless Steel

- Plastic

-

Shaft Type

-

Round Hole

Round Hole -

1-Bearing

1-Bearing -

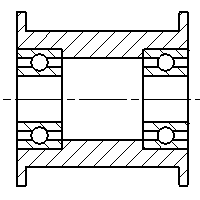

2-Bearing at Center

2-Bearing at Center -

1-Bearing on Each End (2-Bearing in Total)

1-Bearing on Each End (2-Bearing in Total) -

With Shaft

With Shaft

-

-

Surface Urethane

-

Shaft (Bore) Dia. d(mm)

-

Surface Treatment

-

Shaft Type

Narrow search by specifying Manufacturer

Related Categories to Flat Belt Idlers

FAQ Idlers

- Question: What materials are commonly used for manufacturing conveyor rollers (Flat Belt Idlers)?

- Answer: Conveyor rollers (Flat Belt Idlers) are commonly manufactured using materials such as steel, stainless steel, aluminum, and various types of plastics like polypropylene and polyurethane.

- Question: How often should conveyor rollers (Flat Belt Idlers) be maintained?

- Answer: Conveyor rollers (Flat Belt Idlers) should be regularly maintained, typically every three months or as advised by the manufacturer. Regular inspections and maintenance help ensure smooth operation and prevent issues. However, the frequency may vary based on factors like usage, operating conditions, and the materials being transported.

- Question: What are the different types of conveyor rollers (Flat Belt Idlers) available in the market?

- Answer: They have 5 different types of conveyor rollers (Flat Belt Idlers) available in the market,

- Gravity Rollers: Rely on gravity for movement, suitable for inclined or declined conveyors.

- Powered Rollers: Driven by motors or power sources, offering controlled and efficient movement.

- Tapered Rollers: Designed for curves and corners, ensuring smooth transitions.

- Grooved Rollers: Provide extra grip for transporting heavy loads.

- Sprocket Rollers: Used in chain-driven systems, offering positive drive and precise movement. - Question: Can conveyor rollers (Flat Belt Idlers) be used with different types of belts?

- Answer: Yes, conveyor rollers (Flat Belt Idlers) can be used with different types of belts. The design and compatibility of the rollers may vary depending on the specific belt type and its requirements. It's important to ensure that the rollers and belts are compatible in terms of dimensions, load capacity, and any specific features or attachments needed for proper belt tracking and alignment.

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy