(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

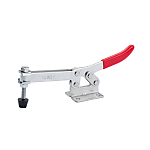

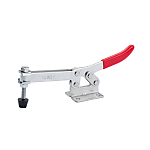

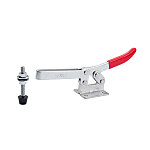

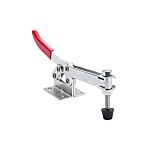

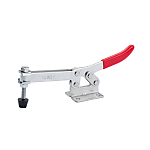

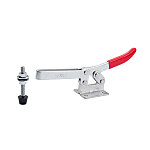

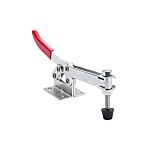

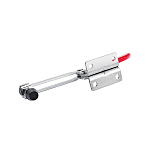

MISUMI Horizontal Hold-Down Toggle Clamps(Attaching Method:Flange Base Page2)

MISUMI offers products Horizontal Hold-Down Toggle Clamps specified by Attaching Method Flange Base from Automation Components product category. There are a total of 46 items. Search and select detailed specifications of parts for your machine with free CAD downloads. MISUMI products are available to order through MISUMI online 24 hours a day. Free shipping, no minimum order.

Brand |

|

|---|---|

| CAD |

|

| Days to Ship |

|

46 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

Bottom Fixed Closing Pressure of Horizontal Toggle Clamp 2270N (Handle Length-increased Type)

MISUMI

- CAD :

- 3D

Attaching Method Tightening Force (Range Selectable)(N) Tightening Force(N) Body Material Clamp Screw Material Tip Screw Type Tip Screw Position Adjustment Clamp Screw Size Flange Base 500~2279 2270 Steel Steel + Rubber Pad Bolt with Rubber Slide Adjustment M8 From: ₹ 1,098.00 Days to Ship: 14 Day(s)  14 Day(s)

14 Day(s)

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Attaching Method |

| Tightening Force (Range Selectable)(N) |

| Tightening Force(N) |

| Body Material |

| Clamp Screw Material |

| Tip Screw Type |

| Tip Screw Position Adjustment |

| Clamp Screw Size |

You can add up to 6 items per a category to the compare list. | |

| Brand | MISUMI |

| Product Series | Bottom Fixed Closing Pressure of Horizontal Toggle Clamp 2270N (Handle Length-increased Type) |

| CAD |

|

| From | ₹ 1,098.00 |

| Days to Ship | 14 Day(s) |

| Attaching Method | Flange Base |

| Tightening Force (Range Selectable)(N) | 500~2279 |

| Tightening Force(N) | 2270 |

| Body Material | Steel |

| Clamp Screw Material | Steel + Rubber Pad |

| Tip Screw Type | Bolt with Rubber |

| Tip Screw Position Adjustment | Slide Adjustment |

| Clamp Screw Size | M8 |

Loading...

Configure

Specification/Dimensions

-

Attaching Method

- Flange Base

- Straight Base

- Side Base

-

Tightening Force (Range Selectable)(N)

-

Tightening Force(N)

-

Body Material

- Steel

- Stainless Steel

-

Clamp Screw Material

- Steel

- Stainless Steel

- Nylon

- Steel + Rubber Pad

-

Tip Screw Type

- Bolt with Rubber

- Steel Bolt

- Stainless Steel Bolt

- Nylon Bolt

- Bolt with Resin

-

Tip Screw Position Adjustment

- Non-adjustable (Fixed)

- Slide Adjustment

-

Clamp Screw Size

Narrow search by specifying Manufacturer

Related Categories to Horizontal Hold-Down Toggle Clamps

FAQ Horizontal Hold-Down Toggle Clamps

- Question: What are Horizontal Hold-Down Toggle Clamps?

- Answer: Horizontal hold-down toggle clamps are fasteners used to secure workpieces to a stable surface, typically a workbench. They function by applying a downward pressing force on the material using a toggle mechanism. This mechanism multiplies a small force applied by the user (through a side-mounted handle) into a larger clamping force holding the workpiece down.

- Question: What types of toggle clamps are available on the market?

- Answer: On the market, you can find vertical, horizontal, push/pull, latch, pneumatic, toggle pliers, adjustable spindle, and quick-release toggle clamps. These clamps vary in their clamping orientations, mechanisms, and features, providing options for different applications and requirements.

- Question: How are toggle clamps different from other types of clamps?

- Answer: Toggle clamps differ from other clamps in their mechanism. While most clamps use threaded screws or hydraulic/pneumatic systems, toggle clamps employ a lever system with a pivoting toggle mechanism. This unique design enables quick, one-handed operation, high clamping force, and secure holding of objects, making them efficient and easy to use.

- Question: What are some common applications for toggle clamps?

- Answer: Toggle clamps are commonly used in woodworking, metalworking, assembly, fixturing, jigs, testing and inspection applications. They provide secure clamping for cutting, drilling, welding, machining, fabrication, component assembly, repetitive tasks, gluing, painting, sanding, and precise positioning in robotics and automation processes.

- Question: What types of workpieces are suitable for horizontal hold-down toggle clamps?

- Answer: THorizontal hold-down toggle clamps are suitable for securing flat or horizontally-oriented workpieces, such as boards, panels, sheets, and fixtures.

- Question: What safety considerations should be taken when using toggle clamps?

- Answer: When using toggle clamps, it is important to consider safety measures such as proper installation and secure mounting, regular inspection and maintenance, utilization of personal protective equipment, adherence to manufacturer guidelines, gradual application of clamping force, awareness of pinch points and entanglement hazards, and maintaining a safe distance and direction when releasing the clamping force.

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy