(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

MISUMI Locating Pins(Insertion Guide Tip Type:Tapered Page3)

|

Basic Shape

|

|

|---|---|

Brand |

|

| CAD |

|

| Days to Ship |

|

103 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

MISUMI

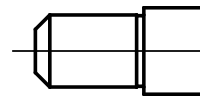

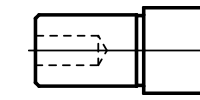

- Feed Pins - Solid – Tapped from MISUMI.

- Length of tapered part can be specified depending on applications or environment. It is attached with a female thread.

- SUS304 feed Pins may not be polished and may have no centering hole.

- The material of pin can be selected 3 types, steel SKS3 Equivalent, stainless steel SUS304, SUS440C or 13Cr stainless.

- The tightening torque (ref. value) for hardened products is strength class 8.8. Not applicable when using locking materials or lock washers.Basic Shape Environmentally friendly Characteristics/Applications Insertion Guide Tip Shape Insertion Guide Tip Type Insertion Guide Specifications Mounting Side Shape Surface Treatment Heat Treatment Material Insertion Guide Outer Dia. D1(mm) Insertion Guide Tolerance Mounting Side Outer Dia. d(mm) Mounting Side Tolerance Cleaning Method Large Head - - Round Tapered Not Provided Tapped Not Provided / Hard Chrome Plating Not Provided / Directly Quenching Steel / Stainless Steel 6.5 ~ 13 0/-0.01 6 ~ 10 g6 - Days to Ship: 7 Day(s) or more  7 Day(s) or more

7 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

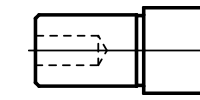

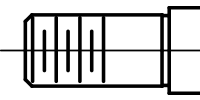

Feed Pins - Shouldered - Press Fit

MISUMI

Locating Pins with the tapered part configurable to be longer. The Shoulder supports the workpiece so that it will not damage the base.

Basic Shape Environmentally friendly Characteristics/Applications Insertion Guide Tip Shape Insertion Guide Tip Type Insertion Guide Specifications Mounting Side Shape Surface Treatment Heat Treatment Material Insertion Guide Outer Dia. D1(mm) Insertion Guide Tolerance Mounting Side Outer Dia. d(mm) Mounting Side Tolerance Cleaning Method Shouldered - - Round Tapered Not Provided Straight (Press-Fit) Not Provided / Hard Chrome Plating Not Provided / Directly Quenching Steel / Stainless Steel 2 ~ 11 0/-0.01 2 ~ 10 m6 - Days to Ship: 7 Day(s) or more  7 Day(s) or more

7 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Feed Pins - Shouldered - Tapped

MISUMI

Locating Pins with the tapered part configurable to be longer. The Shoulder supports the workpiece so that it will not damage the base.

Basic Shape Environmentally friendly Characteristics/Applications Insertion Guide Tip Shape Insertion Guide Tip Type Insertion Guide Specifications Mounting Side Shape Surface Treatment Heat Treatment Material Insertion Guide Outer Dia. D1(mm) Insertion Guide Tolerance Mounting Side Outer Dia. d(mm) Mounting Side Tolerance Cleaning Method Shouldered - - Round Tapered Not Provided Tapped Not Provided / Hard Chrome Plating Not Provided / Directly Quenching Steel / Stainless Steel 4 ~ 11 0/-0.01 6 ~ 10 g6 - Days to Ship: 7 Day(s) or more  7 Day(s) or more

7 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Feed Pins - Shouldered - Threaded

MISUMI

Locating Pins with the tapered part configurable to be longer. The Shoulder supports the workpiece so that it will not damage the base.

Basic Shape Environmentally friendly Characteristics/Applications Insertion Guide Tip Shape Insertion Guide Tip Type Insertion Guide Specifications Mounting Side Shape Surface Treatment Heat Treatment Material Insertion Guide Outer Dia. D1(mm) Insertion Guide Tolerance Mounting Side Outer Dia. d(mm) Mounting Side Tolerance Cleaning Method Shouldered - - Round Tapered Not Provided Threaded Not Provided / Hard Chrome Plating Not Provided / Directly Quenching Steel / Stainless Steel 2 ~ 11 0/-0.01 3 ~ 10 g6 - Days to Ship: 7 Day(s) or more  7 Day(s) or more

7 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Locating Pins - High Hardness Stainless Steel, Small Head, Tapered (Tapped)

MISUMI

For High Hardness Stainless Steel, Small Head Tapered Type, the configurable range of dimensions has been further widened. For order of up to 1,000 pcs., the 7th Day Shipping is available.

Basic Shape Environmentally friendly Characteristics/Applications Insertion Guide Tip Shape Insertion Guide Tip Type Insertion Guide Specifications Mounting Side Shape Surface Treatment Heat Treatment Material Insertion Guide Outer Dia. D1(mm) Insertion Guide Tolerance Mounting Side Outer Dia. d(mm) Mounting Side Tolerance Cleaning Method Small Head - - Round / Diamond Tapered Not Provided Tapped Not Provided Not Provided Stainless Steel 4 ~ 16 0/-0.01 6 ~ 16 g6 ~ h7 - Days to Ship: 8 Day(s) or more  8 Day(s) or more

8 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

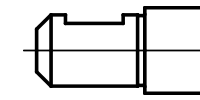

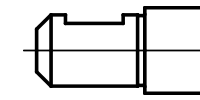

Locating Pins Double Stepped - Tapped

MISUMI

[Features]Suitable for positioning workpieces with different hole diameters. It is attached with a female thread.

Basic Shape Environmentally friendly Characteristics/Applications Insertion Guide Tip Shape Insertion Guide Tip Type Insertion Guide Specifications Mounting Side Shape Surface Treatment Heat Treatment Material Insertion Guide Outer Dia. D1(mm) Insertion Guide Tolerance Mounting Side Outer Dia. d(mm) Mounting Side Tolerance Cleaning Method Double-Stepped - - Round Tapered Not Provided Tapped Not Provided / Hard Chrome Plating Not Provided / Directly Quenching Steel / Stainless Steel 6 ~ 30 0/-0.01 6 ~ 20 g6 - Days to Ship: 7 Day(s) or more  7 Day(s) or more

7 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Locating Pins - Large Head, Tapered - Nonmagnetic - Threaded

MISUMI

Nonmagnetic (Aluminum) Locating Pins. Does not magnetically affect the surroundings.

Basic Shape Environmentally friendly Characteristics/Applications Insertion Guide Tip Shape Insertion Guide Tip Type Insertion Guide Specifications Mounting Side Shape Surface Treatment Heat Treatment Material Insertion Guide Outer Dia. D1(mm) Insertion Guide Tolerance Mounting Side Outer Dia. d(mm) Mounting Side Tolerance Cleaning Method Large Head - - Round / Diamond Tapered Not Provided Threaded Anodize Not Provided Aluminum 3.5 ~ 25 0/-0.01 3 ~ 16 g6 - Days to Ship: 8 Day(s) or more  8 Day(s) or more

8 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

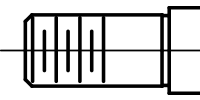

Locating Pins - Large/Small Head, Tapered (Set Screw-Notch Shape)

MISUMI

Large Head/Small Head, Tapered, Set Screw Type. Selectable from Circumference Groove, Notched and Set Screw Flat Shapes.

Basic Shape Environmentally friendly Characteristics/Applications Insertion Guide Tip Shape Insertion Guide Tip Type Insertion Guide Specifications Mounting Side Shape Surface Treatment Heat Treatment Material Insertion Guide Outer Dia. D1(mm) Insertion Guide Tolerance Mounting Side Outer Dia. d(mm) Mounting Side Tolerance Cleaning Method Large Head / Small Head - - Round / Diamond Tapered Not Provided Notch Not Provided / Hard Chrome Plating Not Provided / Directly Quenching Steel / Stainless Steel 5 ~ 30 0/-0.01 6 ~ 20 g6 - Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Locating Pins - Shouldered-Taper Angle (D,P Tolerance Selectable-Tapped)

MISUMI

[Features]You can freely specify dimensions of shoulder type respective parts. It is attached with a female thread.

- Volume Discount

Basic Shape Environmentally friendly Characteristics/Applications Insertion Guide Tip Shape Insertion Guide Tip Type Insertion Guide Specifications Mounting Side Shape Surface Treatment Heat Treatment Material Insertion Guide Outer Dia. D1(mm) Insertion Guide Tolerance Mounting Side Outer Dia. d(mm) Mounting Side Tolerance Cleaning Method Shouldered - - Round Tapered Not Provided Tapped Not Provided / Hard Chrome Plating Not Provided / Directly Quenching Steel / Stainless Steel 4 ~ 20 0/-0.01 ~ h7 6 ~ 20 g6 ~ h7 - Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Locating Pins - Shouldered (Set Screw-Set Screw Flat)

MISUMI

Shouldered Set Screw Type. Selectable from Circumference Groove, Notched and Set Screw Flat Shapes.

Basic Shape Environmentally friendly Characteristics/Applications Insertion Guide Tip Shape Insertion Guide Tip Type Insertion Guide Specifications Mounting Side Shape Surface Treatment Heat Treatment Material Insertion Guide Outer Dia. D1(mm) Insertion Guide Tolerance Mounting Side Outer Dia. d(mm) Mounting Side Tolerance Cleaning Method Shouldered - - Round / Diamond Tapered Not Provided Set Screw Flat Not Provided Directly Quenching Steel 5 ~ 30 0/-0.01 6 ~ 20 g6 - Days to Ship: 6 Day(s)  6 Day(s)

6 Day(s)

-

You can add up to 6 items per a category to the compare list.

Locating Pin High-Hardness Stainless Head Taper -Male Thread-

MISUMI

Shouldered and Tapered Type has been newly added to the High Hardness Stainless Steel Locating Pin product line-up. For orders of up to 500 pcs., 5th day shipping is available.

Basic Shape Environmentally friendly Characteristics/Applications Insertion Guide Tip Shape Insertion Guide Tip Type Insertion Guide Specifications Mounting Side Shape Surface Treatment Heat Treatment Material Insertion Guide Outer Dia. D1(mm) Insertion Guide Tolerance Mounting Side Outer Dia. d(mm) Mounting Side Tolerance Cleaning Method Shouldered - - Round / Diamond Tapered - Threaded Not Provided Not Provided Stainless Steel 2 ~ 13 - 3 ~ 12 - - Days to Ship: 8 Day(s) or more  8 Day(s) or more

8 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

![[Clean & Pack] Locating Pin - Large Head, Tapered, Press Fit](//content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/v1/p/jp/product/series/110310664379/110310664379_001_20230911105917.jpg?$product_view_b$)

[Clean & Pack] Locating Pin - Large Head, Tapered, Press Fit

MISUMI

Three types of cleaning methods are available: degreasing, precision cleaning, and electrolytic polishing + precision cleaning. They can be ordered from one piece with the standard part number.

This eliminates the need for customer cleaning or outsourced cleaning, reducing the amount of time and effort required.■Part Number for Clean & Pack Products·Degreasing (Anti-rust single packing) : Part Number SL-□□ ·Precision cleaning (Degassing double packing) : Part Number SH-□□ ·Electrolytic polishing + precision cleaning (Degassing double packing) : Part Number SHD-□□ Product Part Number Cleaning Method Packaging Type Effects Compared to Uncleaned Product Environment (Standard) Process SL-□□ Degreasing Anti-rust packing Oil removal General environment Regular assembly process Post battery assembly process SH-□□ Precision cleaning Degassing double packing Oil removal

Dust removalClean environment (Class 10 to 1,000) Battery assembly process LCD-related post assembly process In-vehicle camera assembly process SHD-□□ Electrolytic polishing + precision cleaning Degassing double packing Oil removal

Dust removal

Outgas reductionVacuum environment

Clean environment (Class 10 to 1,000)Pre-semiconductor process Liquid crystal deposition process Pre-OLED process ■Notes

Cleaning also removes rust prevention oil, which may make the product more susceptible to rusting than an uncleaned product.

Please be careful about the application location and storage environment.- Volume Discount

Basic Shape Environmentally friendly Characteristics/Applications Insertion Guide Tip Shape Insertion Guide Tip Type Insertion Guide Specifications Mounting Side Shape Surface Treatment Heat Treatment Material Insertion Guide Outer Dia. D1(mm) Insertion Guide Tolerance Mounting Side Outer Dia. d(mm) Mounting Side Tolerance Cleaning Method Large Head RoHS Compliant (10 Substances) Clean Washed Round / Diamond Tapered Not Provided Straight (Press-Fit) Not Provided / Hard Chrome Plating Not Provided Stainless Steel 1.2 ~ 30 0/-0.01 1 ~ 20 g6 ~ p6 Degreasing / Precision Cleaning / Electrolytic Polishing + Precision Cleaning Days to Ship: 9 Day(s) or more  9 Day(s) or more

9 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

![[Clean & Pack] Locating Pin - Small Head, Tapered, Press Fit](//content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/v1/p/jp/product/series/110310664649/110310664649_001_20230911105917.jpg?$product_view_b$)

[Clean & Pack] Locating Pin - Small Head, Tapered, Press Fit

MISUMI

Three types of cleaning methods are available: degreasing, precision cleaning, and electrolytic polishing + precision cleaning. They can be ordered from one piece with the standard part number.

This eliminates the need for customer cleaning or outsourced cleaning, reducing the amount of time and effort required.■Part Number for Clean & Pack Products·Degreasing (Anti-rust single packing) : Part Number SL-□□ ·Precision cleaning (Degassing double packing) : Part Number SH-□□ ·Electrolytic polishing + precision cleaning (Degassing double packing) : Part Number SHD-□□ Product Part Number Cleaning Method Packaging Type Effects Compared to Uncleaned Product Environment (Standard) Process SL-□□ Degreasing Anti-rust packing Oil removal General environment Regular assembly process Post battery assembly process SH-□□ Precision cleaning Degassing double packing Oil removal

Dust removalClean environment (Class 10 to 1,000) Battery assembly process LCD-related post assembly process In-vehicle camera assembly process SHD-□□ Electrolytic polishing + precision cleaning Degassing double packing Oil removal

Dust removal

Outgas reductionVacuum environment

Clean environment (Class 10 to 1,000)Pre-semiconductor process Liquid crystal deposition process Pre-OLED process ■Notes

Cleaning also removes rust prevention oil, which may make the product more susceptible to rusting than an uncleaned product.

Please be careful about the application location and storage environment.- Volume Discount

Basic Shape Environmentally friendly Characteristics/Applications Insertion Guide Tip Shape Insertion Guide Tip Type Insertion Guide Specifications Mounting Side Shape Surface Treatment Heat Treatment Material Insertion Guide Outer Dia. D1(mm) Insertion Guide Tolerance Mounting Side Outer Dia. d(mm) Mounting Side Tolerance Cleaning Method Small Head RoHS Compliant (10 Substances) Clean Washed Round / Diamond Tapered Not Provided Straight (Press-Fit) Not Provided / Hard Chrome Plating Not Provided Stainless Steel 1 ~ 20 0/-0.01 2 ~ 20 m6 ~ p6 Degreasing / Precision Cleaning / Electrolytic Polishing + Precision Cleaning Days to Ship: 9 Day(s) or more  9 Day(s) or more

9 Day(s) or more

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Basic Shape |

| Environmentally friendly |

| Characteristics/Applications |

| Insertion Guide Tip Shape |

| Insertion Guide Tip Type |

| Insertion Guide Specifications |

| Mounting Side Shape |

| Surface Treatment |

| Heat Treatment |

| Material |

| Insertion Guide Outer Dia. D1(mm) |

| Insertion Guide Tolerance |

| Mounting Side Outer Dia. d(mm) |

| Mounting Side Tolerance |

| Cleaning Method |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| Brand | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI |

| Product Series | Locating Pins - High Hardness Stainless Steel, Small Head, Tapered (Tapped) | Locating Pins - Large Head, Tapered - Nonmagnetic - Threaded | Locating Pins - Large/Small Head, Tapered (Set Screw-Notch Shape) | Locating Pins - Shouldered-Taper Angle (D,P Tolerance Selectable-Tapped) | Locating Pin High-Hardness Stainless Head Taper -Male Thread- | [Clean & Pack] Locating Pin - Large Head, Tapered, Press Fit | [Clean & Pack] Locating Pin - Small Head, Tapered, Press Fit | ||||||

| CAD |

|

|

|

|

|

|

|

|

|

|

|

|

|

| From | - | - | - | - | - | - | - | - | - | - | - | - | - |

| Days to Ship | 7 Day(s) or more | 7 Day(s) or more | 7 Day(s) or more | 7 Day(s) or more | 8 Day(s) or more | 7 Day(s) or more | 8 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) | 8 Day(s) or more | 9 Day(s) or more | 9 Day(s) or more |

| Basic Shape | Large Head | Shouldered | Shouldered | Shouldered | Small Head | Double-Stepped | Large Head | Large Head / Small Head | Shouldered | Shouldered | Shouldered | Large Head | Small Head |

| Environmentally friendly | - | - | - | - | - | - | - | - | - | - | - | RoHS Compliant (10 Substances) | RoHS Compliant (10 Substances) |

| Characteristics/Applications | - | - | - | - | - | - | - | - | - | - | - | Clean Washed | Clean Washed |

| Insertion Guide Tip Shape | Round | Round | Round | Round | Round / Diamond | Round | Round / Diamond | Round / Diamond | Round | Round / Diamond | Round / Diamond | Round / Diamond | Round / Diamond |

| Insertion Guide Tip Type | Tapered | Tapered | Tapered | Tapered | Tapered | Tapered | Tapered | Tapered | Tapered | Tapered | Tapered | Tapered | Tapered |

| Insertion Guide Specifications | Not Provided | Not Provided | Not Provided | Not Provided | Not Provided | Not Provided | Not Provided | Not Provided | Not Provided | Not Provided | - | Not Provided | Not Provided |

| Mounting Side Shape | Tapped | Straight (Press-Fit) | Tapped | Threaded | Tapped | Tapped | Threaded | Notch | Tapped | Set Screw Flat | Threaded | Straight (Press-Fit) | Straight (Press-Fit) |

| Surface Treatment | Not Provided / Hard Chrome Plating | Not Provided / Hard Chrome Plating | Not Provided / Hard Chrome Plating | Not Provided / Hard Chrome Plating | Not Provided | Not Provided / Hard Chrome Plating | Anodize | Not Provided / Hard Chrome Plating | Not Provided / Hard Chrome Plating | Not Provided | Not Provided | Not Provided / Hard Chrome Plating | Not Provided / Hard Chrome Plating |

| Heat Treatment | Not Provided / Directly Quenching | Not Provided / Directly Quenching | Not Provided / Directly Quenching | Not Provided / Directly Quenching | Not Provided | Not Provided / Directly Quenching | Not Provided | Not Provided / Directly Quenching | Not Provided / Directly Quenching | Directly Quenching | Not Provided | Not Provided | Not Provided |

| Material | Steel / Stainless Steel | Steel / Stainless Steel | Steel / Stainless Steel | Steel / Stainless Steel | Stainless Steel | Steel / Stainless Steel | Aluminum | Steel / Stainless Steel | Steel / Stainless Steel | Steel | Stainless Steel | Stainless Steel | Stainless Steel |

| Insertion Guide Outer Dia. D1(mm) | 6.5 ~ 13 | 2 ~ 11 | 4 ~ 11 | 2 ~ 11 | 4 ~ 16 | 6 ~ 30 | 3.5 ~ 25 | 5 ~ 30 | 4 ~ 20 | 5 ~ 30 | 2 ~ 13 | 1.2 ~ 30 | 1 ~ 20 |

| Insertion Guide Tolerance | 0/-0.01 | 0/-0.01 | 0/-0.01 | 0/-0.01 | 0/-0.01 | 0/-0.01 | 0/-0.01 | 0/-0.01 | 0/-0.01 ~ h7 | 0/-0.01 | - | 0/-0.01 | 0/-0.01 |

| Mounting Side Outer Dia. d(mm) | 6 ~ 10 | 2 ~ 10 | 6 ~ 10 | 3 ~ 10 | 6 ~ 16 | 6 ~ 20 | 3 ~ 16 | 6 ~ 20 | 6 ~ 20 | 6 ~ 20 | 3 ~ 12 | 1 ~ 20 | 2 ~ 20 |

| Mounting Side Tolerance | g6 | m6 | g6 | g6 | g6 ~ h7 | g6 | g6 | g6 | g6 ~ h7 | g6 | - | g6 ~ p6 | m6 ~ p6 |

| Cleaning Method | - | - | - | - | - | - | - | - | - | - | - | Degreasing / Precision Cleaning / Electrolytic Polishing + Precision Cleaning | Degreasing / Precision Cleaning / Electrolytic Polishing + Precision Cleaning |

Loading...

Configure

Specification/Dimensions

-

Environmentally friendly

-

Characteristics/Applications

-

Insertion Guide Tip Shape

-

Round

Round -

Diamond

Diamond -

Square Head

Square Head -

Triangle

Triangle

-

-

Insertion Guide Tip Type

-

Tapered

Tapered -

Round Tapered

Round Tapered -

Taper R

Taper R -

R

R -

Spherical

Spherical -

Flat

Flat -

Bullet Nose

Bullet Nose

-

-

Insertion Guide Specifications

-

Not Provided

Not Provided -

With Screw Mount Hole

With Screw Mount Hole -

With Hex Socket

With Hex Socket -

With Flathead Slot

With Flathead Slot

-

-

Mounting Side Shape

-

Straight (Press-Fit)

Straight (Press-Fit) -

Tapped

Tapped -

Threaded

Threaded -

Circumference Groove

Circumference Groove -

Notch

Notch -

Set Screw Flat

Set Screw Flat

-

-

Surface Treatment

- Not Provided

- Black Oxide

- Electroless Nickel Plating

- Hard Chrome Plating

- Buffed

- Hard Chrome Plating + Buffed

- Anodize

-

Heat Treatment

- Not Provided

- Carburized

- Directly Quenching

-

Material

- Steel

- Stainless Steel

- Resin

- Aluminum

-

Insertion Guide Outer Dia. D1(mm)

-

Insertion Guide Tolerance

-

Mounting Side Outer Dia. d(mm)

-

Mounting Side Tolerance

-

Cleaning Method

- Degreasing

- Precision Cleaning

- Electrolytic Polishing + Precision Cleaning

Narrow search by specifying Manufacturer

Related Categories to Locating Pins

FAQ Locating Pins

- Question: What are locating pins?

- Answer: Locating pins are essential components used in factory automation to achieve precise alignment and positioning of workpieces during assembly and machining processes. These pins are inserted into precision holes or bushings to establish accurate alignment and prevent movement or misalignment of parts.

- Question: What are the main benefits of using locating pins?

- Answer: The use of locating pins offers several benefits in factory automation. They ensure accurate and repeatable positioning, improving the overall quality and consistency of assembled products. Locating pins also enhance productivity by reducing assembly time and minimizing errors. They provide stability and prevent movement or shifting of components, resulting in better alignment and fit. Additionally, locating pins help to maintain proper tolerances and ensure efficient machining processes.

- Question: What are the different types of locating pins?

- Answer: Locating pins come in various types, including:

Dowel Pins: Cylindrical pins with a tight tolerance fit used for precise alignment.

Tapered Pins: Conical pins that provide self-centering capability.

Shoulder Pins: Featuring a step or shoulder to provide accurate positioning at a specific depth.

Spring-Loaded Pins: Pins with spring mechanisms for automatic retraction and engagement.

Floating Pins: Pins designed to allow slight movement for accommodating manufacturing tolerances. - Question: What materials are locating pins made from?

- Answer: Locating pins are typically made from durable and corrosion-resistant materials such as hardened steel, stainless steel, or tungsten carbide. The choice of material depends on the specific application requirements, including load capacity, environmental conditions, and desired longevity.

- Question: How do I install and use locating pins effectively?

- Answer: To install locating pins, align the pin with the pre-drilled hole or bushing and gently insert it until it is securely in place. Ensure that the pin fits snugly and does not protrude excessively. When using locating pins, it is essential to follow the design specifications and guidelines provided by the manufacturer. Proper maintenance, including periodic cleaning and lubrication, can also help ensure optimal performance and longevity of locating pins.

![[Clean & Pack] Locating Pin - Large Head, Tapered, Press Fit](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/v1/p/jp/product/series/110310664379/110310664379_001_20230911105917.jpg?$product_view_b$)

![[Clean & Pack] Locating Pin - Small Head, Tapered, Press Fit](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_b/v1/p/jp/product/series/110310664649/110310664649_001_20230911105917.jpg?$product_view_b$)

![[Clean & Pack] Locating Pin - Large Head, Tapered, Press Fit](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_c/v1/p/jp/product/series/110310664379/110310664379_001_20230911105917.jpg?$product_view_c$)

![[Clean & Pack] Locating Pin - Small Head, Tapered, Press Fit](http://content.misumi-ec.com/image/upload/f_auto,q_auto,t_product_view_c/v1/p/jp/product/series/110310664649/110310664649_001_20230911105917.jpg?$product_view_c$)

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy