(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

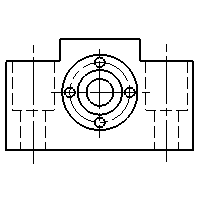

MISUMI Support Units(Mounting Method:Bottom Mount)

|

Type

|

|

|---|---|

Brand |

|

| CAD |

|

| Days to Ship |

|

2 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

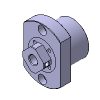

Support Units-Fixed Side/Square/Compact

MISUMI

This is the most compact type among MISUMI support units.

- Volume Discount

Type Shape Shaft Dia. d(Ø) Mounting Method Bearing Type Shaft Height H(mm) Bearing Grade Surface Treatment Thickness B(mm) Width W(mm) Support Material Outer Dia. D(Ø) Fixed Side Square 8 ~ 15 Bottom Mount Angular Contact Bearing 17 ~ 30 Grade 0 Black Oxide / Electroless Nickel Plating 23 ~ 29 32 ~ 46 Steel - From: ₹ 5,395.96 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

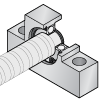

Support Units-Support Side/Square/Compact

MISUMI

When used in conjunction with the same series on the fixed side, space-saving designs can be easily achieved. Ideal for small devices!

- Volume Discount

Type Shape Shaft Dia. d(Ø) Mounting Method Bearing Type Shaft Height H(mm) Bearing Grade Surface Treatment Thickness B(mm) Width W(mm) Support Material Outer Dia. D(Ø) Support Side Square 6 ~ 15 Bottom Mount - 17 ~ 30 - Black Oxide / Electroless Nickel Plating 15 ~ 20 32 ~ 46 Steel - From: ₹ 2,055.14 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Type |

| Shape |

| Shaft Dia. d(Ø) |

| Mounting Method |

| Bearing Type |

| Shaft Height H(mm) |

| Bearing Grade |

| Surface Treatment |

| Thickness B(mm) |

| Width W(mm) |

| Support Material |

| Outer Dia. D(Ø) |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| Brand | MISUMI | MISUMI |

| Product Series | ||

| CAD |

|

|

| From | ₹ 5,395.96- | ₹ 2,055.14- |

| Days to Ship | 6 Day(s) or more | 6 Day(s) or more |

| Type | Fixed Side | Support Side |

| Shape | Square | Square |

| Shaft Dia. d(Ø) | 8 ~ 15 | 6 ~ 15 |

| Mounting Method | Bottom Mount | Bottom Mount |

| Bearing Type | Angular Contact Bearing | - |

| Shaft Height H(mm) | 17 ~ 30 | 17 ~ 30 |

| Bearing Grade | Grade 0 | - |

| Surface Treatment | Black Oxide / Electroless Nickel Plating | Black Oxide / Electroless Nickel Plating |

| Thickness B(mm) | 23 ~ 29 | 15 ~ 20 |

| Width W(mm) | 32 ~ 46 | 32 ~ 46 |

| Support Material | Steel | Steel |

| Outer Dia. D(Ø) | - | - |

Loading...

Configure

Specification/Dimensions

-

Shape

-

Square

Square -

Round

Round -

Round, 2 Set Screw Flats at both ends

Round, 2 Set Screw Flats at both ends

-

-

Shaft Dia. d(Ø)

-

Mounting Method

-

Bearing Type

- Angular Contact Bearing

- Radial Bearing, Single

- Radial Bearing, Double

-

Shaft Height H(mm)

-

Bearing Grade

-

Surface Treatment

- Black Oxide

- Electroless Nickel Plating

- Low Temperature Black Chrome Plating

-

Thickness B(mm)

-

Width W(mm)

-

Support Material

-

Outer Dia. D(Ø)

Narrow search by specifying Manufacturer

Related Categories to Support Units

FAQ Ball Screw Support Units

- Question: What are Ball Screw Support Units?

- Answer: Ball screw support units are essential components used to support and stabilize ball screws in linear motion systems. They play a crucial role in ensuring smooth, precise, and reliable operation of the system.

- Question: Why are Ball Screw Support Units Important?

- Answer: • Precision and Accuracy: Support units help maintain the accuracy and precision of the linear motion system by preventing deflection and vibration of the ball screw.

• Extended Lifespan: Proper support reduces friction and wear on the ball screw, leading to a longer lifespan.

• Reduced Noise and Vibration: Effective support units minimize noise and vibration, improving overall system performance and user experience. - Question: What are the Different Types of Ball Screw Support Units?

- Answer: • Pillow Block Bearings: These are simple and economical support units that provide basic support to the ball screw.

• Flanged Bearings: These units are attached to a mounting surface using bolts and are suitable for various applications.

• Compact Support Units: These are compact and lightweight units that offer high rigidity and precision.

• Adjustable Support Units: These units allow for fine-tuning of the ball screw alignment and can accommodate variations in installation. - Question: What Are the Common Applications of Ball Screw Support Units?

- Answer: Ball Screw Support Units are widely used in applications requiring precise linear motion, including

• CNC Machines: Used to support the ball screws in the X, Y, and Z axes.

• Industrial Robots: Provide support for the robotic arm's linear motion.

• 3D Printers: Essential for precise positioning of the print head.

• Medical Equipment: Used in various medical devices requiring precise linear motion.

• Semiconductor Manufacturing Equipment: Support high-precision motion systems.

• Packaging Machinery: Ensure accurate and reliable packaging processes.

Their design helps maintain accuracy and stability in high-load, high-speed environments. - Question: How Does Thermal Expansion Affect Ball Screw Support Units?

- Answer: Thermal expansion can impact the performance of Ball Screw Support Units, especially in high-speed applications. The floating support unit allows the ball screw to expand and contract without causing misalignment or binding, while the fixed support holds the ball screw steady. Proper support design prevents temperature-induced issues.

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy