(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

ATEC Ball Rollers(Type:Spring-Loaded)

Brand |

|

|---|---|

| CAD |

|

| Days to Ship |

|

2 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

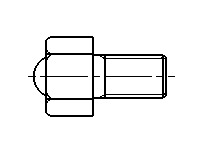

Plain bear PV-C/CF Series spring cushion type

ATEC

Heavy objects are moved back and forth / left and right on the plain bearing to position. For mold positioning, when clamping the lower mold, the ball roller sinks, and the lower mold and the bolster are fixed together. Can also be used as caster for descending use.

- CAD :

- 2D

Load Capacity(N) Shape Type Outer Dia. D(Ø) Load Capacity Range(N) Body Material Ball Material 68 ~ 686 Cylindrical / Flange Spring-Loaded 20 ~ 60 50.1~100.0 / 100.1~500.0 / 500.1~5000 Steel Steel From: ₹ 373.53 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

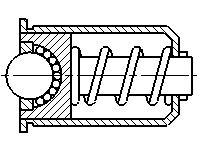

Spring Cushion Type Plain Bearing PV-BC Series

ATEC

Spring prevents concentrated loads on plain bearing due to installation level difference etc.

[Features]

· The internal spring prevents concentrated loads on the plain bearing, making it easy and fast for jigs, mold exchanges and positioning.

· Free motion control / freer heavy load transport.

· Space saving can be achieved with a layout tailored to the work environment- CAD :

- 2D

Load Capacity(N) Shape Type Outer Dia. D(Ø) Load Capacity Range(N) Body Material Ball Material 490 ~ 1176 Flange Spring-Loaded 70 ~ 88 100.1~500.0 / 500.1~5000 Steel Steel From: ₹ 5,284.51 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Load Capacity(N) |

| Shape |

| Type |

| Outer Dia. D(Ø) |

| Load Capacity Range(N) |

| Body Material |

| Ball Material |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| Brand | ATEC | ATEC |

| Product Series | ||

| CAD |

|

|

| From | ₹ 373.53- | ₹ 5,284.51- |

| Days to Ship | 5 Day(s) or more | 5 Day(s) or more |

| Load Capacity(N) | 68 ~ 686 | 490 ~ 1176 |

| Shape | Cylindrical / Flange | Flange |

| Type | Spring-Loaded | Spring-Loaded |

| Outer Dia. D(Ø) | 20 ~ 60 | 70 ~ 88 |

| Load Capacity Range(N) | 50.1~100.0 / 100.1~500.0 / 500.1~5000 | 100.1~500.0 / 500.1~5000 |

| Body Material | Steel | Steel |

| Ball Material | Steel | Steel |

Loading...

Configure

Specification/Dimensions

-

Load Capacity(N)

- 1

- 2

- 4

- 4.9

- 5

- 6

- 7

- 8

- 8.8

- 9.8

- 10

- 11

- 12

- 14

- 14.7

- 19.6

- 19.62

- 21

- 23

- 24

- 27

- 29.4

- 33

- 34

- 41

- 44 (4.5)

- 49

- 49.05

- 49.6 (5)

- 50

- 55

- 62

- 68

- 68.6

- 69

- 78

- 78.4

- 78.48

- 78.5

- 82

- 98

- 98.1

- 107

- 117.6 (12)

- 147

- 157

- 176

- 196

- 196.1

- 196.2

- 216

- 245

- 274 (28)

- 274.4 (28)

- 284

- 294

- 294.2

- 294.3

- 330 (34)

- 343

- 392

- 412

- 470.4 (48)

- 490

- 490.5

- 510

- 588

- 588.6

- 686

- 730

- 784

- 784.5

- 784.8

- 882

- 980

- 1020

- 1056

- 1080

- 1176

- 1176 (120)

- 1180

- 1296

- 1372

- 1470

- 1471.5

- 1510

- 1512

- 1530

- 1568

- 1570

- 1728

- 1764

- 1910

- 1944

- 1960

- 1962

- 2040

- 2160

- 2200

- 2292

- 2320

- 2376

- 2450

- 2548

- 2550

- 2592

- 2640

- 2646

- 2744

- 2800

- 2940

- 2943

- 3020

- 3024

- 3056

- 3060

- 3240

- 3380

- 3430

- 3438

- 3528

- 3570

- 3630

- 3672

- 3680

- 3820

- 3870

- 3920

- 4080

- 4104

- 4116

- 4202

- 4320

- 4410

- 4500

- 4530

- 4536

- 4584

- 4732

- 4900

- 4905

- 5100

- 5150

- 5348

- 5390

- 5400

- 5408

- 5610

- 5730

- 5880

- 6040

- 6084

- 6120

- 6620

- 6750

- 7130

- 7350

- 7550

- 7640

- 8090

- 8112

- 8150

- 8660

- 8788

- 8820

- 9060

- 9120

- 9170

- 9464

- 9560

- 9680

- 9800

- 10140

- 10300

- 10600

- 11000

- 11760

- 11800

- 12100

- 12500

- 13200

- 13600

- 14000

- 14700

- 14872

- 15100

- 16600

- 18100

- 19600

- 21100

- 22600

- 24100

- 25700

- 27200

- 28700

- No

-

Shape

-

Type

-

Outer Dia. D(Ø)

- 8

- 9

- 10

- 11

- 12

- 12.2

- 13

- 15

- 15.8

- 16

- 16.5

- 17

- 18

- 18.5

- 19

- 19.2

- 19.5

- 20

- 20.5

- 21

- 22

- 23

- 24

- 25

- 25.7

- 25.8

- 26

- 27

- 27.5

- 28

- 29

- 30

- 31

- 32

- 33

- 34

- 34.5

- 35

- 36

- 38

- 39

- 39.5

- 41

- 41.3

- 42

- 44

- 45

- 46

- 47

- 48

- 50

- 50.2

- 51

- 51.5

- 52

- 53

- 55

- 55.5

- 55.8

- 56

- 57

- 58

- 59.3

- 60

- 65

- 65.2

- 66

- 67

- 69

- 70

- 71

- 71.8

- 72

- 75

- 76

- 77

- 78

- 80

- 85

- 88

- 95

- 96

- 96.8

- 100

- 107

- 110

- 120

- 130

- 140

- 151.2

- 155

- 180

- 187

- 200

- 304

- 401

- 456

- No

-

Load Capacity Range(N)

- 1.0~10.0

- 10.1~20.0

- 20.1~50.0

- 50.1~100.0

- 100.1~500.0

- 500.1~5000

- 5000.1~10000

- 10000.1~20000

- 20000.1 or more

-

Body Material

- Steel

- Stainless Steel

- Plastic

- Aluminum

-

Ball Material

- Steel

- Stainless Steel

- Plastic

Narrow search by specifying Manufacturer

-

- MISUMI (2)

- FREEBEAR (3)

- ATEC (2)

- IGUCHI KIKO (1)

- TAKIGEN (1)

- MAKITECH (0)

- FUJI SEISAKUSHO (0)

- TRUSCO NAKAYAMA (0)

Related Categories to Ball Rollers

FAQ Ball Rollers

- Question: What is a ball roller and how does it work?

- Answer: A ball roller , also known as a ball transfer unit, is a device used in material handling applications to facilitate the movement of objects. It consists of multiple small ball bearings held within a housing. The balls are designed to rotate freely, allowing objects to be smoothly transferred or rotated in any direction.

- Question: What are the advantages of using ball rollers in material handling applications?

- Answer: Ball roller offer several advantages in material handling applications. They provide a low-friction surface, enabling easy and smooth movement of objects. Ball transfers allow for multidirectional movement, making them suitable for applications that require quick and efficient changes in direction. They are also durable, capable of handling heavy loads, and can be easily integrated into conveyor systems or workstations.

- Question: What types of ball rollers are available?

- Answer: Conveyor ball rollers: These are commonly used in conveyor systems to transport goods or materials along a predetermined path.

Ball transfer units: These are individual units with multiple balls arranged in a housing, allowing objects to be easily rotated or moved in any direction.

Heavy-duty ball rollers: Designed to withstand higher loads and harsher operating conditions, these rollers are commonly used in industrial settings. - Question: How do you select the right type of ball roller for your specific application?

- Answer: When selecting a ball roller , consider factors such as the weight and size of the objects being transferred, the operating environment, and the desired movement flexibility. It is important to choose a ball transfer with a load capacity that meets your application requirements. Consulting with a supplier or engineer can help determine the appropriate type and specifications for your specific needs.

- Question: What are the different materials used to make ball rollers and how do they affect performance?

- Answer: Ball roller can be made from various materials, including steel, stainless steel, and plastic. Steel ball transfers offer high load capacity and durability, making them suitable for heavy-duty applications. Stainless steel transfers are corrosion-resistant and ideal for environments with moisture or harsh chemicals. Plastic transfers are lightweight and non-corrosive, suitable for lighter loads and quieter operation. The choice of material depends on factors such as load capacity, operating conditions, and specific application requirements.

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy