(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Please note that the MISUMI India offices and warehouses will remain closed from Oct 31st to Nov 3rd due to the Diwali festival.

Please note that the MISUMI Pune office and warehouse will be closed on November 20th due to the state election. - Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

KASHIMA Cartridge Heaters(Rated Capacity (Range):100~169)

Brand |

|

|---|---|

| CAD |

|

| Days to Ship |

|

1 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

Cartridge Heater for High Temperatures TYPE A

KASHIMA

A cartridge heater made by the US company RAMA.High-temperature cartridge heater widely used for heating molds.For use at high temperatures, Incoloy is used for the sheath material, an Incoloy end disc is welded to the cartridge heater terminal, and a LavaSeal (special lava seal) is provided on the opening. It has been manufactured in a strictly controlled production process.Continuous sheath surface temperatures of up to 871°C can be maintained in addition to accurate and uniform heating at medium and low temperatures.A wide range of heater diameters are available, from φ6.25 to φ18.95. 332 types are consistently in stock.Customized items of different sizes and shapes can be manufactured within a short delivery time.UL standard products are also available with short delivery times.

[Notes]

· Max. Operating Temperature: 871°C (Heater Surface Temperature)

· Lead wire heat resistance temperature is 200°C.

· The vicinity of the lead wire exit port should be kept at or below 130°C.

· We recommend drilling holes to align the actual product, because malfunctioning heat exchange leading to abnormal heat generation that will shorten operation life occurs when the clearance between the mold hole inner diameter and heater outer diameter increases on heaters with a power density of 20 W/cm² or more.

· Note that the insulating tube easily comes off.

· Do not use the heater while empty in open air. There is a risk of breaking or catching fire due to abnormal heat generation if used with all or part of the heater protruding from the object being heated.- CAD :

- 2D

Maximum Operating Temperature(°C) Rated Voltage(V) Diameter D (Range)(Ø) Length L (Range)(mm) Rated Capacity (Range)(W) Product Category 871 110~120 ~ 220~ ~8 ~ 8.1–9.9 ~51 ~ 71~129 100~169 Heaters From: ₹ 4,186.40 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Maximum Operating Temperature(°C) |

| Rated Voltage(V) |

| Diameter D (Range)(Ø) |

| Length L (Range)(mm) |

| Rated Capacity (Range)(W) |

| Product Category |

You can add up to 6 items per a category to the compare list. | |

| Brand | KASHIMA |

| Product Series | |

| CAD |

|

| From | ₹ 4,186.40- |

| Days to Ship | 6 Day(s) or more |

| Maximum Operating Temperature(°C) | 871 |

| Rated Voltage(V) | 110~120 ~ 220~ |

| Diameter D (Range)(Ø) | ~8 ~ 8.1–9.9 |

| Length L (Range)(mm) | ~51 ~ 71~129 |

| Rated Capacity (Range)(W) | 100~169 |

| Product Category | Heaters |

Loading...

Configure

Specification/Dimensions

-

Maximum Operating Temperature(°C)

-

Rated Voltage(V)

-

Diameter D (Range)(Ø)

-

Length L (Range)(mm)

-

Rated Capacity (Range)(W)

-

Product Category

- Heaters

- Mounting Components

Narrow search by specifying Manufacturer

Related Categories to Cartridge Heaters

FAQ Cartridge Heaters

- Question: What is a cartridge heater and what are its general properties?

- Answer: A cartridge heater is a type of heating element commonly used in industries such as plastic molding, packaging, and sealing. It finds application in heating solids, liquids, and gases. the structure of a cartridge heater consists of a cylindrical metal tube, which is made of stainless steel, with an electrical resistance wire wound inside. The resistance wire generates heat when an electric current passes through it.

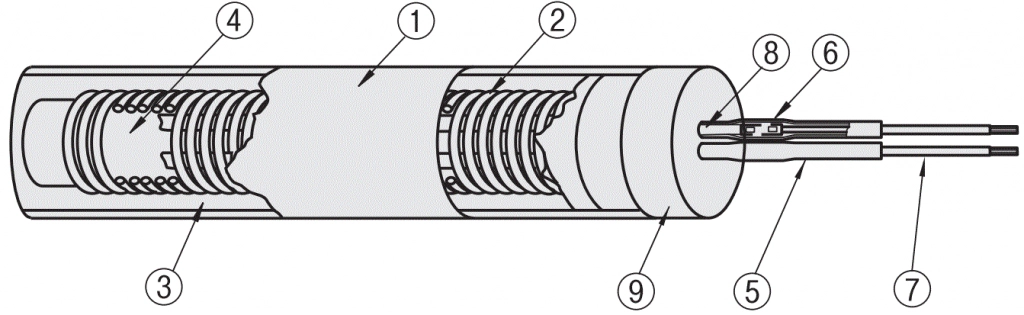

- Question: What is the structure of a cartridge heater?

- Answer: Essential component in catride heater consist of

1. Stainless steel sheath (Incoloy for High Temperature Type)

2. Heating Coil (Nickel-chrome Wire)

3. Insulation Powder (Magnesium Oxide)

4. Ceramic Core

5. Silicon (Insulation) Tube

6. Crimp Terminal

7. Lead Wire Sheath

8. Nickel Pin

9. Insulator

- Question: What are the benefits of using a cartridge heater?

- Answer: The benefits of using a cartridge heater

1. High Heating Efficiency

2. Precise Temperature Control: especially important in scientific and laboratory equipment.

3. Compact and Space-Saving: Cartridge heaters are compact and can be easily installed into equipment or systems with limited space.

4. Durability and Longevity:

5. Versatility and Customization such as diameter, length, wattage, voltage, lead wire configuration, and termination options.

6. Fast Response Time This attribute is beneficial in applications where frequent heating and cooling cycles.

7. Easy Installation and Maintenance: easy to install, often inserted into a hole or mounted using various clamping mechanisms. Their simple design and accessibility facilitate maintenance and replacement when needed.

8. Cost-Effective Solution: They minimize energy consumption, reduce downtime associated with heating processes, and require less frequent replacement compared to some other heating methods. - Question: How is a cartridge heater typically used in industrial applications?

- Answer: Cartridge heaters are typical uses in a variety of industrial applications such as

1. Plastic Molding: They are inserted into the mold to heat and maintain the desired temperature of the mold cavity

2. Packaging and Sealing: The cartridge heaters are used to heat sealing bars, platens, or dies. for sealing and bonding of materials like plastic films, laminates etc.

3. Hot Runner Systems: Cartridge heaters are an integral part of hot runner systems in injection molding.

4. Food Processing: Cartridge heaters are maintaining consistent temperatures in ovens, grills, fryers, and cooking equipment.

5. Heat Treatment: Cartridge heaters are utilized in heat treatment processes like annealing, tempering, or stress relieving of metal parts.

6. Medical Equipment: Such as sterilization chambers, incubators, and laboratory instruments. - Question: What are some common industries or applications that make use of cartridge heaters?

- Answer: Cartridge heaters are common uses in a variety of industrial applications such as

1. Plastic Molding: for example plastic injection mold

2. Packaging and Sealing: for example heat sealing bars, platens, or dies

3. Food Processing: for example in ovens, grills, fryers, and cooking equipment.

4. Heat Treatment: for example in heat treatment processes like annealing, tempering, or stress relieving of metal parts.

5. Medical Equipment: for example sterilization chambers, incubators, and laboratory instruments.

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy