(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

Turning Inserts(O.D./ I.D. (For Threading):Internal Diameter)

An online store for inserts (for turning). In MISUMI's e-catalog, specifications/dimensions of brand, shape, application, compatible work materials, etc. can be selected with one click, so you can easily find the desired product.

An online store for inserts (for turning). In MISUMI's e-catalog, specifications/dimensions of brand, shape, application, compatible work materials, etc. can be selected with one click, so you can easily find the desired product.

[What is turning?]

A shape is created by rotating the work material and cutting the surface while pressing the cutting edge. Processing methods can be divided into outer diameter processing, threading, inner diameter processing, and cut-off processing. The model numbers written on the insert and holder are codes unique to each tool manufacturer. Understanding how to read the model number provides basic information such as shape, type, and size. In many cases, cutting conditions are written on the label of the insert case, so check it before use.

Brand |

|

|---|---|

| CAD |

|

| Days to Ship |

|

44 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

Trapezoidal Thread Cutting Tip

(TR) for Internal Thread ISCAR

ISCAR thread-cutting tool.

Shape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) T (Triangle) Steel / Stainless Steel / Heat-resistant alloy, titanium alloy Threading 3 Finish - Other Right-hand - 2 ~ 5 Internal Diameter Trapezoid 30° - From: ₹ 2,025.51 Days to Ship: 7 Day(s) or more  7 Day(s) or more

7 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

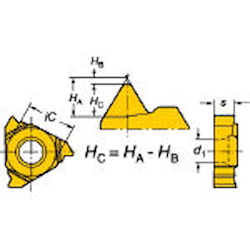

T-Max U Lock UN 60° With Finishing Blade

SANDVIK

Shape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) T (Triangle) Steel / Stainless Steel / Cast Iron / Non-ferrous metal / Heat-resistant alloy, titanium alloy / High Hardness Material Threading 3 Finish - - Right-hand / Left-hand - - Internal Diameter unified 60° 14TPI ~ 32TPI From: ₹ 2,250.53 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

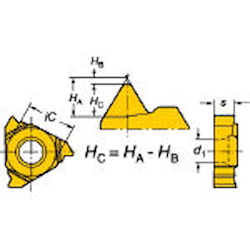

T-Max U-Lock Threading Insert R/L166.0..MM..

SANDVIK

[Features]

T-Max U-Lock, insert for threading

Solid carbide-coated insert

Quick-change type

For inner-diameter threading

For metric threads

Machining pitch: for 3.0 mmShape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) T (Triangle) Steel / Stainless Steel / Cast Iron / Non-ferrous metal / Heat-resistant alloy, titanium alloy / High Hardness Material Threading 3 - - - Left-hand - 1.25 mm ~ 1.75 mm Internal Diameter - - From: ₹ 2,442.07 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

ISO Meter Thread Cutting Tip (ISO) Finishing Blade (Flat Drag)

ISCAR

ISCAR thread-cutting tool.

Shape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) T (Triangle) Steel / Stainless Steel / Heat-resistant alloy, titanium alloy Threading 3 Finish - Other Right-hand - 0.5 ~ 5 Internal Diameter ISO Meter 60° - From: ₹ 1,207.15 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

CoroThread 266 V-Shaped 55° Without Finishing Blade

SANDVIK

[Features]

CoroThread 266, insert for threading

Solid carbide-coated insert

Newly designed inserts with improved ease of mounting and a guide rail with high clamp rigidity

For inner-diameter threading

Without finishing blade, for 55° threads

Machining pitch: for 7-4 threadsShape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) T (Triangle) Steel / Stainless Steel / Cast Iron / Non-ferrous metal / Heat-resistant alloy, titanium alloy Threading 3 - - Other Left-hand - - Internal Diameter - 14-8TPI ~ 28-14TPI From: ₹ 2,853.25 Days to Ship: 8 Day(s) or more  8 Day(s) or more

8 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

ACME Trapezoid 29° Thread Crest, With Chamfering Blade

SANDVIK

[Features]

CoroThread 266, insert for threading

Solid carbide-coated insert

Newly designed inserts with improved ease of mounting and a guide rail with high clamp rigidity

For outer-diameter threading

For ACME trapezoidal 29° threads

Machining pitch: for 4 threadsShape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) T (Triangle) Steel / Stainless Steel / Cast Iron / Non-ferrous metal / Heat-resistant alloy, titanium alloy Threading 3 - - - Right-hand / Left-hand - - Internal Diameter Trapezoid 29° 3TPI ~ 12TPI From: ₹ 3,228.29 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

STUB-ACME 29° Thread Crest, With Chamfering Blade

SANDVIK

Shape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) T (Triangle) Steel / Stainless Steel / Cast Iron / Non-ferrous metal / Heat-resistant alloy, titanium alloy Threading 3 - - - Right-hand / Left-hand - - Internal Diameter - 3TPI ~ 12TPI From: ₹ 3,228.29 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Acme Threading Tip (ACME) Finished Blade Type with (Flat Cutting Edge)

ISCAR

ISCAR thread-cutting tool.

Shape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) T (Triangle) Steel / Stainless Steel / Heat-resistant alloy, titanium alloy Threading 3 Finish - Other Right-hand - - Internal Diameter Trapezoid 29° 5 ~ 8 From: ₹ 2,025.51 Days to Ship: 7 Day(s) or more  7 Day(s) or more

7 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Cut Grip Tip GEPI (Peripheral Grinding Type Tip)

ISCAR

Cut Grip GEHSR / L-SL Series Tip

Shape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) Other Steel / Stainless Steel / Cast Iron / Heat-resistant alloy, titanium alloy Outer Diameter/Inner Diameter 2 Finish - 0.2 ~ Other No-hand 1.00(±0.02) ~ 3.18(±0.02) - Internal Diameter - - From: ₹ 2,462.86 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

PICCO-CUT Small-Diameter Solid Bar 002, 003, 004, 005, 006, 007, for Grooving/Boring

ISCAR

Small Diameter Solid Bar, 002, 003, 004, 005, 006, 007

Shape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) Other Steel / Stainless Steel / Heat-resistant alloy, titanium alloy Outer Diameter/Inner Diameter 1 Finish - Other Right-hand / Left-hand - - Internal Diameter - - From: ₹ 4,034.60 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Inner Diameter Thread Cutting Tip

KYOCERA

60° inner diameter threading insert with flat cutting blade.

Shape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) T (Triangle) Steel / Stainless Steel / Cast Iron / Non-ferrous metal Threading 3 - Pozidriv 0.2 ~ Other Right-hand - 0.5–1.5 ~ 5 Internal Diameter unified 60° / General Purpose 60° / General Purpose 55° / Taper for Pipes 55° / Trapezoid 30° 16 ~ 19 From: ₹ 900.96 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Cut Grip Tip GEMI (M Type Tip)

ISCAR

Cut Grip GEHSR / L-SL Series Tip

Shape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) Other Steel / Stainless Steel / Heat-resistant alloy, titanium alloy Outer Diameter/Inner Diameter 2 Finish - 0.2 No-hand 3.00(±0.03) - Internal Diameter - - From: ₹ 3,092.86 Days to Ship: 7 Day(s) or more  7 Day(s) or more

7 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Cam Groove Tip GFQR-12 (for Edge Groove Machining)

ISCAR

For End Face Grooving

Shape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) Other Steel / Stainless Steel / Cast Iron / Heat-resistant alloy, titanium alloy Grooving / Parting 1 Finish - 0.2 ~ Other Right-hand 1.0(±0.02) ~ 2.5(±0.02) - Internal Diameter - - From: ₹ 5,075.71 Days to Ship: 7 Day(s) or more  7 Day(s) or more

7 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Cam Groove Tip GIQR / L-8/11 (for Grooving, Turning and Copying)

ISCAR

For Grooving, Turning, and Profiling

Shape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) Other Steel / Stainless Steel / Cast Iron / Heat-resistant alloy, titanium alloy Grooving / Parting 1 Finish - 0.2 ~ Other Right-hand / Left-hand 0.50(±0.02) ~ 3.00(±0.02) - Internal Diameter - - From: ₹ 2,585.38 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Cut Grip Tip for Inner Diameter Machining (Straight Type)

ISCAR

ISCAR grooving and multi-function tool.

Shape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) Other Steel / Stainless Steel / Cast Iron / Non-ferrous metal / Heat-resistant alloy, titanium alloy Outer Diameter/Inner Diameter 2 Finish Pozidriv 0.2 ~ Other No-hand 1.57(±0.02) ~ 5.00(±0.02) - Internal Diameter - - From: ₹ 2,527.14 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Inner Diameter Thread Cutting Tip 16IR/L○○ISO

KYOCERA

Metric Thread (M) with Flat Blade 60°

Shape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) T (Triangle) Steel / Stainless Steel Threading 3 - Pozidriv Other Right-hand / Left-hand - 1 ~ 2 Internal Diameter ISO Meter 60° - From: ₹ 1,655.04 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

CoroThread 266 NPT 60° NPSC, NPTR, LINEPIPE1) With Finishing Blade

SANDVIK

[Features]

CoroThread 266, insert for threading

Solid carbide-coated insert

Newly designed inserts with improved ease of mounting and a guide rail with high clamp rigidity

For outer-diameter threading

For NPT 60° threads

Machining pitch: for 18 threadsShape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) T (Triangle) Steel / Stainless Steel / Cast Iron / Non-ferrous metal / Heat-resistant alloy, titanium alloy Threading 3 Finish - - Right-hand / Left-hand - - Internal Diameter - 8TPI ~ 14TPI From: ₹ 2,421.98 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

SANDVIK

[Features]

CoroThread 266, insert for threading

Solid carbide-coated insert

Newly designed inserts with improved ease of mounting and a guide rail with high clamp rigidity

For outer-diameter threading

For BSPT 55° threads

Machining pitch: for 11 threadsShape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) T (Triangle) Steel / Stainless Steel / Cast Iron / Non-ferrous metal / Heat-resistant alloy, titanium alloy Threading 3 Finish - - Right-hand / Left-hand - - Internal Diameter - 8TPI ~ 28TPI From: ₹ 2,851.93 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

API 60° With Finishing Blade, For Shoulder Connections

SANDVIK

Shape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) T (Triangle) Steel / Stainless Steel / Cast Iron / Non-ferrous metal / Heat-resistant alloy, titanium alloy Threading 3 Finish - - Right-hand - - Internal Diameter - 4TPI ~ 5TPI From: ₹ 4,878.42 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

T-Max U Lock Whitworth 55° (BSW, BSF, BSP) With Finishing Blade

SANDVIK

[Features]

T-Max U-Lock, insert for threading

Solid carbide-coated insert

Quick-change type

For inner-diameter threading

For NPT 60° threads

For machining operations requiring a sharp blade tip

Machining pitch: for 14 threadsShape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) T (Triangle) Steel / Stainless Steel / Cast Iron / Non-ferrous metal / Heat-resistant alloy, titanium alloy / High Hardness Material Threading 3 Finish - - Right-hand / Left-hand - - Internal Diameter Whitworth 55° 14TPI ~ 20TPI From: ₹ 2,250.53 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Insert For CoroCut MB, For Threading

SANDVIK

Shape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) Other Steel / Stainless Steel / Non-ferrous metal / Heat-resistant alloy, titanium alloy Threading 3 Finish - - Right-hand - - Internal Diameter Trapezoid 29° 8TPI ~ 16TPI From: ₹ 2,699.24 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

BSPT Thread Cutting Tip (BSPT) With Finish Blade (Wiper Insert) Type

ISCAR

ISCAR thread-cutting tool.

Shape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) T (Triangle) Steel / Stainless Steel / Heat-resistant alloy, titanium alloy Threading 3 Finish - Other Right-hand - - Internal Diameter - 11 ~ 19 From: ₹ 1,207.15 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

ISCAR

ISCAR thread-cutting tool.

Shape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) T (Triangle) Steel / Stainless Steel / Heat-resistant alloy, titanium alloy Threading 3 Finish - Other Right-hand - - Internal Diameter - 8 ~ 18 From: ₹ 1,207.15 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Whitworth Threading Tip (W) Finished Blade Type with (Flat Cutting Edge)

ISCAR

ISCAR thread-cutting tool.

Shape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) T (Triangle) Steel / Stainless Steel / Heat-resistant alloy, titanium alloy Threading 3 Finish - 0.2 ~ Other Right-hand - - Internal Diameter Whitworth 55° 8 ~ 24 From: ₹ 1,207.15 Days to Ship: 7 Day(s) or more  7 Day(s) or more

7 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Cut Grip Tip GEPI...RX/LX (Peripheral Grinding Type Corner Processing Tip)

ISCAR

Cut Grip GEHSR / L-SL Series Tip

Shape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) Other Steel / Stainless Steel / Cast Iron / Heat-resistant alloy, titanium alloy Outer Diameter/Inner Diameter 2 Finish - Other Right-hand / Left-hand 1.00(±0.02) - Internal Diameter - - From: ₹ 3,327.14 Days to Ship: 7 Day(s) or more  7 Day(s) or more

7 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Cut Grip Tip GEPI...UR/UL/UN (Peripheral Grinding Type Undercut Processing Tip)

ISCAR

Cut Grip GEHSR / L-SL Series Tip

Shape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) Other Steel / Stainless Steel / Cast Iron / Heat-resistant alloy, titanium alloy Outer Diameter/Inner Diameter 2 Finish - Other Right-hand / Left-hand / No-hand 2.00(±0.02) ~ 3.00(±0.02) - Internal Diameter - - From: ₹ 3,572.86 Days to Ship: 7 Day(s) or more  7 Day(s) or more

7 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Cam Groove Tip GIQR / L-MT/WT (for Threat Cutting)

ISCAR

For Threading

Shape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) Other Steel / Stainless Steel / Cast Iron / Heat-resistant alloy, titanium alloy Threading 1 Finish - Other Right-hand / Left-hand - - Internal Diameter - - From: ₹ 4,254.29 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Cam Groove Tip GIQR / L-R (for Full R Groove, Copying)

ISCAR

Full Radius Groove, for Profiling

Shape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) Other Steel / Stainless Steel / Cast Iron / Heat-resistant alloy, titanium alloy Grooving / Parting 1 Finish - Other Right-hand / Left-hand 1.2(±0.02) ~ 3.0(±0.02) - Internal Diameter - - From: ₹ 3,998.57 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

PICCO-CUT Small-Diameter Solid Bar 004, 005, 006, 007, Full-Rounded Type

ISCAR

Small Diameter Solid Bar, 004, 005, 006, 007

Shape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) Other Steel / Stainless Steel / Heat-resistant alloy, titanium alloy Outer Diameter/Inner Diameter 1 Finish - Other Right-hand - - Internal Diameter - - From: ₹ 4,752.53 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

PICCO-CUT Small-Diameter Solid Bar 050, 053, 055, for Boring/chamfering

ISCAR

Small Diameter Solid Bar, 050, 053, 055

Shape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) Other Steel / Stainless Steel / Heat-resistant alloy, titanium alloy Outer Diameter/Inner Diameter 1 Finish - Other Right-hand / Left-hand - - Internal Diameter - - From: ₹ 3,102.38 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

PICCO-CUT Small-Diameter Solid Bar 520 for Chamfering

ISCAR

Small-Diameter Solid Bar, 520

Shape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) Other Steel / Stainless Steel / Heat-resistant alloy, titanium alloy Outer Diameter/Inner Diameter 1 Finish - 0.2 Right-hand - - Internal Diameter - - From: ₹ 6,114.69 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Unified Screw Thread Cutting Tips (UN) with Finishing Teeth (Rake Blade) Type

ISCAR

ISCAR thread-cutting tool.

Shape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) T (Triangle) Steel / Stainless Steel / Heat-resistant alloy, titanium alloy Threading 3 Finish - Other Right-hand - - Internal Diameter unified 60° 8 ~ 20 From: ₹ 1,207.15 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

No Finishing Edge (Cutting Edge) Type 55° Threading Tip

ISCAR

ISCAR thread-cutting tool.

Shape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) T (Triangle) Steel / Stainless Steel / Heat-resistant alloy, titanium alloy Threading 3 Finish - Other Right-hand - 0.50-3.00 ~ 1.75-2.00 Internal Diameter General Purpose 55° 14-11 ~ 48-8 From: ₹ 1,207.15 Days to Ship: 7 Day(s) or more  7 Day(s) or more

7 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

No Finishing Edge (Cutting Edge) Type 60° Threading Tip

ISCAR

ISCAR thread-cutting tool.

Shape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) T (Triangle) Steel / Stainless Steel / Heat-resistant alloy, titanium alloy Threading 3 Finish - Other Right-hand - 0.50-3.00 ~ 3.50-5.00 Internal Diameter General Purpose 60° 7-5 ~ 48-8 From: ₹ 1,207.15 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Inner Diameter Thread Cutting Tip WHITWORTH

ISCAR

A super-high productivity insert.

Shape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) T (Triangle) Steel / Stainless Steel / Heat-resistant alloy, titanium alloy Threading 3 Finish - Other Right-hand - - Internal Diameter Whitworth 55° 14 From: ₹ 2,621.55 Days to Ship: 7 Day(s) or more  7 Day(s) or more

7 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Cross-Thread 266 Thread Cutting CBN Tip

SANDVIK

Unique shape exhibits high performance

Shape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) T (Triangle) Steel / Stainless Steel / Cast Iron / Non-ferrous metal / Heat-resistant alloy, titanium alloy Threading 1 - - - Right-hand - 1.5-3mm Internal Diameter - 16-8TPI From: ₹ 16,444.09 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Inner Diameter Thread Cutting Tip 11IR/L○○ISO-TF

KYOCERA

Metric Thread (M) with Flat Blade 60°

Shape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) T (Triangle) Steel / Stainless Steel Threading 3 - Pozidriv Other Right-hand - 1 Internal Diameter ISO Meter 60° - From: ₹ 913.02 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Inner Diameter Thread Cutting Tip 11IR/L○○ISO

KYOCERA

Metric Thread (M) with Flat Blade 60°

Shape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) T (Triangle) Steel / Stainless Steel / Cast Iron / Non-ferrous metal Threading 3 - Pozidriv Other Right-hand - 0.5 ~ 1.75 Internal Diameter ISO Meter 60° - From: ₹ 1,522.44 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Inner Diameter Thread Cutting Tip 22IR/L○○ISO

KYOCERA

Metric Thread (M) with Flat Blade 60°

Shape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) T (Triangle) Steel / Stainless Steel Threading 3 - Pozidriv Other Right-hand - 5 Internal Diameter ISO Meter 60° - From: ₹ 2,694.40 Days to Ship: 7 Day(s) or more  7 Day(s) or more

7 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

SANDVIK

Shape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) T (Triangle) Steel / Stainless Steel / Cast Iron / Non-ferrous metal / Heat-resistant alloy, titanium alloy Threading 3 Finish - - Right-hand - - Internal Diameter - 8TPI ~ 14TPI From: ₹ 3,153.29 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Round 30° With Finishing Blade

SANDVIK

Shape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) T (Triangle) Steel / Stainless Steel / Cast Iron / Non-ferrous metal / Heat-resistant alloy, titanium alloy Threading 3 Finish - - Right-hand / Left-hand - - Internal Diameter - 4TPI ~ 10TPI From: ₹ 2,421.98 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

API Round 60° With Finishing Blade

SANDVIK

Shape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) T (Triangle) Steel / Stainless Steel / Cast Iron / Non-ferrous metal / Heat-resistant alloy, titanium alloy Threading 3 Finish - - Right-hand - - Internal Diameter - 8TPI ~ 10TPI From: ₹ 3,548.40 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

API With Finishing Blade, For Tubing & Casing

SANDVIK

Shape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) T (Triangle) Steel / Stainless Steel / Cast Iron / Non-ferrous metal / Heat-resistant alloy, titanium alloy Threading 3 - - - Right-hand - - Internal Diameter - 5TPI From: ₹ 5,111.47 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Outer Diameter Threading Tip (Multi-Edged Type / Multi-Edged Tip) ISO (Metric)

ISCAR

[Features]

· Multi-edged threading tips consist of 2 to 3 blades for a reduced number of passes and a shorter machining time (ultra-high productivity tips.)Shape work material Application Available corners Breaker Use Rake angle Nose R Selfishly Groove Width (For Grooving / Plunging) Pitch (for Threading) O.D./ I.D. (For Threading) Screw Types (for threading) Number of threads (for threading) - Steel / Stainless Steel Outer Diameter/Inner Diameter - - - - Right-hand - 3 Internal Diameter - - From: ₹ 5,289.62 Days to Ship: 8 Day(s) or more  8 Day(s) or more

8 Day(s) or more

| Brand |

|---|

| Product Series |

| From |

| Days to Ship |

| Shape |

| work material |

| Application |

| Available corners |

| Breaker Use |

| Rake angle |

| Nose R |

| Selfishly |

| Groove Width (For Grooving / Plunging) |

| Pitch (for Threading) |

| O.D./ I.D. (For Threading) |

| Screw Types (for threading) |

| Number of threads (for threading) |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| Brand | ISCAR | SANDVIK | SANDVIK | ISCAR | SANDVIK | SANDVIK | SANDVIK | ISCAR | ISCAR | ISCAR | KYOCERA | ISCAR | ISCAR | ISCAR | ISCAR | KYOCERA | SANDVIK | SANDVIK | SANDVIK | SANDVIK | SANDVIK | ISCAR | ISCAR | ISCAR | ISCAR | ISCAR | ISCAR | ISCAR | ISCAR | ISCAR | ISCAR | ISCAR | ISCAR | ISCAR | ISCAR | SANDVIK | KYOCERA | KYOCERA | KYOCERA | SANDVIK | SANDVIK | SANDVIK | SANDVIK | ISCAR |

| Product Series | ISO Meter Thread Cutting Tip (ISO) Finishing Blade (Flat Drag) | Acme Threading Tip (ACME) Finished Blade Type with (Flat Cutting Edge) | PICCO-CUT Small-Diameter Solid Bar 002, 003, 004, 005, 006, 007, for Grooving/Boring | Cam Groove Tip GIQR / L-8/11 (for Grooving, Turning and Copying) | CoroThread 266 NPT 60° NPSC, NPTR, LINEPIPE1) With Finishing Blade | T-Max U Lock Whitworth 55° (BSW, BSF, BSP) With Finishing Blade | BSPT Thread Cutting Tip (BSPT) With Finish Blade (Wiper Insert) Type | Whitworth Threading Tip (W) Finished Blade Type with (Flat Cutting Edge) | Cut Grip Tip GEPI...RX/LX (Peripheral Grinding Type Corner Processing Tip) | Cut Grip Tip GEPI...UR/UL/UN (Peripheral Grinding Type Undercut Processing Tip) | PICCO-CUT Small-Diameter Solid Bar 004, 005, 006, 007, Full-Rounded Type | PICCO-CUT Small-Diameter Solid Bar 050, 053, 055, for Boring/chamfering | Unified Screw Thread Cutting Tips (UN) with Finishing Teeth (Rake Blade) Type | Outer Diameter Threading Tip (Multi-Edged Type / Multi-Edged Tip) ISO (Metric) | ||||||||||||||||||||||||||||||

| From | ₹ 2,025.51 | ₹ 2,250.53 | ₹ 2,442.07 | ₹ 1,207.15 | ₹ 2,853.25 | ₹ 3,228.29 | ₹ 3,228.29 | ₹ 2,025.51 | ₹ 2,462.86 | ₹ 4,034.60 | ₹ 900.96 | ₹ 3,092.86 | ₹ 5,075.71 | ₹ 2,585.38 | ₹ 2,527.14 | ₹ 1,655.04 | ₹ 2,421.98 | ₹ 2,851.93 | ₹ 4,878.42 | ₹ 2,250.53 | ₹ 2,699.24 | ₹ 1,207.15 | ₹ 1,207.15 | ₹ 1,207.15 | ₹ 3,327.14 | ₹ 3,572.86 | ₹ 4,254.29 | ₹ 3,998.57 | ₹ 4,752.53 | ₹ 3,102.38 | ₹ 6,114.69 | ₹ 1,207.15 | ₹ 1,207.15 | ₹ 1,207.15 | ₹ 2,621.55 | ₹ 16,444.09 | ₹ 913.02 | ₹ 1,522.44 | ₹ 2,694.40 | ₹ 3,153.29 | ₹ 2,421.98 | ₹ 3,548.40 | ₹ 5,111.47 | ₹ 5,289.62 |

| Days to Ship | 7 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 5 Day(s) or more | 8 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 7 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 7 Day(s) or more | 7 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 7 Day(s) or more | 7 Day(s) or more | 7 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 7 Day(s) or more | 5 Day(s) or more | 7 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 7 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 6 Day(s) or more | 8 Day(s) or more |

| Shape | T (Triangle) | T (Triangle) | T (Triangle) | T (Triangle) | T (Triangle) | T (Triangle) | T (Triangle) | T (Triangle) | Other | Other | T (Triangle) | Other | Other | Other | Other | T (Triangle) | T (Triangle) | T (Triangle) | T (Triangle) | T (Triangle) | Other | T (Triangle) | T (Triangle) | T (Triangle) | Other | Other | Other | Other | Other | Other | Other | T (Triangle) | T (Triangle) | T (Triangle) | T (Triangle) | T (Triangle) | T (Triangle) | T (Triangle) | T (Triangle) | T (Triangle) | T (Triangle) | T (Triangle) | T (Triangle) | - |

| work material | Steel / Stainless Steel / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel / Cast Iron / Non-ferrous metal / Heat-resistant alloy, titanium alloy / High Hardness Material | Steel / Stainless Steel / Cast Iron / Non-ferrous metal / Heat-resistant alloy, titanium alloy / High Hardness Material | Steel / Stainless Steel / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel / Cast Iron / Non-ferrous metal / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel / Cast Iron / Non-ferrous metal / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel / Cast Iron / Non-ferrous metal / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel / Cast Iron / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel / Cast Iron / Non-ferrous metal | Steel / Stainless Steel / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel / Cast Iron / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel / Cast Iron / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel / Cast Iron / Non-ferrous metal / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel | Steel / Stainless Steel / Cast Iron / Non-ferrous metal / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel / Cast Iron / Non-ferrous metal / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel / Cast Iron / Non-ferrous metal / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel / Cast Iron / Non-ferrous metal / Heat-resistant alloy, titanium alloy / High Hardness Material | Steel / Stainless Steel / Non-ferrous metal / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel / Cast Iron / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel / Cast Iron / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel / Cast Iron / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel / Cast Iron / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel / Cast Iron / Non-ferrous metal / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel | Steel / Stainless Steel / Cast Iron / Non-ferrous metal | Steel / Stainless Steel | Steel / Stainless Steel / Cast Iron / Non-ferrous metal / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel / Cast Iron / Non-ferrous metal / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel / Cast Iron / Non-ferrous metal / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel / Cast Iron / Non-ferrous metal / Heat-resistant alloy, titanium alloy | Steel / Stainless Steel |

| Application | Threading | Threading | Threading | Threading | Threading | Threading | Threading | Threading | Outer Diameter/Inner Diameter | Outer Diameter/Inner Diameter | Threading | Outer Diameter/Inner Diameter | Grooving / Parting | Grooving / Parting | Outer Diameter/Inner Diameter | Threading | Threading | Threading | Threading | Threading | Threading | Threading | Threading | Threading | Outer Diameter/Inner Diameter | Outer Diameter/Inner Diameter | Threading | Grooving / Parting | Outer Diameter/Inner Diameter | Outer Diameter/Inner Diameter | Outer Diameter/Inner Diameter | Threading | Threading | Threading | Threading | Threading | Threading | Threading | Threading | Threading | Threading | Threading | Threading | Outer Diameter/Inner Diameter |

| Available corners | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 2 | 1 | 3 | 2 | 1 | 1 | 2 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 2 | 2 | 1 | 1 | 1 | 1 | 1 | 3 | 3 | 3 | 3 | 1 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | - |

| Breaker Use | Finish | Finish | - | Finish | - | - | - | Finish | Finish | Finish | - | Finish | Finish | Finish | Finish | - | Finish | Finish | Finish | Finish | Finish | Finish | Finish | Finish | Finish | Finish | Finish | Finish | Finish | Finish | Finish | Finish | Finish | Finish | Finish | - | - | - | - | Finish | Finish | Finish | - | - |

| Rake angle | - | - | - | - | - | - | - | - | - | - | Pozidriv | - | - | - | Pozidriv | Pozidriv | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | Pozidriv | Pozidriv | Pozidriv | - | - | - | - | - |

| Nose R | Other | - | - | Other | Other | - | - | Other | 0.2 ~ Other | Other | 0.2 ~ Other | 0.2 | 0.2 ~ Other | 0.2 ~ Other | 0.2 ~ Other | Other | - | - | - | - | - | Other | Other | 0.2 ~ Other | Other | Other | Other | Other | Other | Other | 0.2 | Other | Other | Other | Other | - | Other | Other | Other | - | - | - | - | - |

| Selfishly | Right-hand | Right-hand / Left-hand | Left-hand | Right-hand | Left-hand | Right-hand / Left-hand | Right-hand / Left-hand | Right-hand | No-hand | Right-hand / Left-hand | Right-hand | No-hand | Right-hand | Right-hand / Left-hand | No-hand | Right-hand / Left-hand | Right-hand / Left-hand | Right-hand / Left-hand | Right-hand | Right-hand / Left-hand | Right-hand | Right-hand | Right-hand | Right-hand | Right-hand / Left-hand | Right-hand / Left-hand / No-hand | Right-hand / Left-hand | Right-hand / Left-hand | Right-hand | Right-hand / Left-hand | Right-hand | Right-hand | Right-hand | Right-hand | Right-hand | Right-hand | Right-hand | Right-hand | Right-hand | Right-hand | Right-hand / Left-hand | Right-hand | Right-hand | Right-hand |

| Groove Width (For Grooving / Plunging) | - | - | - | - | - | - | - | - | 1.00(±0.02) ~ 3.18(±0.02) | - | - | 3.00(±0.03) | 1.0(±0.02) ~ 2.5(±0.02) | 0.50(±0.02) ~ 3.00(±0.02) | 1.57(±0.02) ~ 5.00(±0.02) | - | - | - | - | - | - | - | - | - | 1.00(±0.02) | 2.00(±0.02) ~ 3.00(±0.02) | - | 1.2(±0.02) ~ 3.0(±0.02) | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| Pitch (for Threading) | 2 ~ 5 | - | 1.25 mm ~ 1.75 mm | 0.5 ~ 5 | - | - | - | - | - | - | 0.5–1.5 ~ 5 | - | - | - | - | 1 ~ 2 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | 0.50-3.00 ~ 1.75-2.00 | 0.50-3.00 ~ 3.50-5.00 | - | 1.5-3mm | 1 | 0.5 ~ 1.75 | 5 | - | - | - | - | 3 |

| O.D./ I.D. (For Threading) | Internal Diameter | Internal Diameter | Internal Diameter | Internal Diameter | Internal Diameter | Internal Diameter | Internal Diameter | Internal Diameter | Internal Diameter | Internal Diameter | Internal Diameter | Internal Diameter | Internal Diameter | Internal Diameter | Internal Diameter | Internal Diameter | Internal Diameter | Internal Diameter | Internal Diameter | Internal Diameter | Internal Diameter | Internal Diameter | Internal Diameter | Internal Diameter | Internal Diameter | Internal Diameter | Internal Diameter | Internal Diameter | Internal Diameter | Internal Diameter | Internal Diameter | Internal Diameter | Internal Diameter | Internal Diameter | Internal Diameter | Internal Diameter | Internal Diameter | Internal Diameter | Internal Diameter | Internal Diameter | Internal Diameter | Internal Diameter | Internal Diameter | Internal Diameter |

| Screw Types (for threading) | Trapezoid 30° | unified 60° | - | ISO Meter 60° | - | Trapezoid 29° | - | Trapezoid 29° | - | - | unified 60° / General Purpose 60° / General Purpose 55° / Taper for Pipes 55° / Trapezoid 30° | - | - | - | - | ISO Meter 60° | - | - | - | Whitworth 55° | Trapezoid 29° | - | - | Whitworth 55° | - | - | - | - | - | - | - | unified 60° | General Purpose 55° | General Purpose 60° | Whitworth 55° | - | ISO Meter 60° | ISO Meter 60° | ISO Meter 60° | - | - | - | - | - |

| Number of threads (for threading) | - | 14TPI ~ 32TPI | - | - | 14-8TPI ~ 28-14TPI | 3TPI ~ 12TPI | 3TPI ~ 12TPI | 5 ~ 8 | - | - | 16 ~ 19 | - | - | - | - | - | 8TPI ~ 14TPI | 8TPI ~ 28TPI | 4TPI ~ 5TPI | 14TPI ~ 20TPI | 8TPI ~ 16TPI | 11 ~ 19 | 8 ~ 18 | 8 ~ 24 | - | - | - | - | - | - | - | 8 ~ 20 | 14-11 ~ 48-8 | 7-5 ~ 48-8 | 14 | 16-8TPI | - | - | - | 8TPI ~ 14TPI | 4TPI ~ 10TPI | 8TPI ~ 10TPI | 5TPI | - |

Loading...

Configure

Specification/Dimensions

-

Shape

- C (80° Diamond-Shape)

- D (55° Diamond-Shape)

- R (Circular)

- S (Rectangular)

- T (Triangle)

- V (35° Diamond-Shaped)

- W (Hexagonal Type)

- Other

-

work material

- Steel

- Stainless Steel

- Cast Iron

- Non-ferrous metal

- Heat-resistant alloy, titanium alloy

- High Hardness Material

-

Application

- Outer Diameter/Inner Diameter

- Grooving / Parting

- Threading

- Other

-

Available corners

- 1

- 2

- 3

- 4

- 6

- 8

- 9 or more

-

Breaker Use

- Finish

- Medium grinding

- Medium to deep grinding

- Heavy cutting

- Light Cutting

- Rough cutting

-

Rake angle

- Negative

- Pozidriv

-

Nose R

-

Selfishly

-

Groove Width (For Grooving / Plunging)

-

Pitch (for Threading)

-

O.D./ I.D. (For Threading)

-

Screw Types (for threading)

-

Number of threads (for threading)

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy