(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

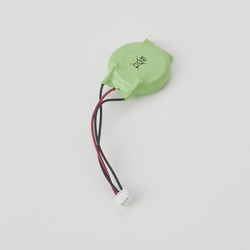

PLC Compatible Batteries

PLC batteries are batteries for control devices in relay circuits. These batteries are used for devices equipped with a relay circuit, such as elevators, escalators, automatic doors and automated machines at factories or other locations. Types such as sequencer replacement batteries and memory backup ba

PLC batteries are batteries for control devices in relay circuits. These batteries are used for devices equipped with a relay circuit, such as elevators, escalators, automatic doors and automated machines at factories or other locations. Types such as sequencer replacement batteries and memory backup batteries are available. When a PLC battery is exhausted, the PLC program will be erased in the event of a power failure and a device failure may occur. Dirt such as dust or oil inside the panel may cause fatal damage to the PLC battery; therefore, thorough cleaning and maintenance are required. When used in a hot environment, high-temperature countermeasures must be taken, such as installing a board cooler, or a fan and louver if there are no resources for a cooler.

Brand |

|

|---|---|

| CAD |

|

| Days to Ship |

|

4 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

From: ₹ 3,218.58 Days to Ship: 5 Day(s) or more  5 Day(s) or more

5 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

MITSUBISHI

Mitsubishi Electric PLC battery. Program memory, standard RAM, large capacity battery for power failure retention of latch device, Q7BATN.

From: ₹ 6,573.55 Days to Ship: 10 Day(s) or more  10 Day(s) or more

10 Day(s) or more

-

You can add up to 6 items per a category to the compare list.

Programmable Controller CPM2C Optional Item

OMRON

Programmable Controller CPM2C Optional Item

- Volume Discount

From: ₹ 4,475.18 Days to Ship: Same day or more  Same day or more

Same day or more

-

You can add up to 6 items per a category to the compare list.

FUJI ELECTRIC

[Features]This is a replacement lithium battery. [Application]Can be used with V907W, V906, V8 series, V7 series, and V606e.

From: ₹ 1,839.74 Days to Ship: 6 Day(s) or more  6 Day(s) or more

6 Day(s) or more

| Brand |

|---|

| Product Series |

| From |

| Days to Ship |

You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | You can add up to 6 items per a category to the compare list. | |

| Brand | OMRON | MITSUBISHI | OMRON | FUJI ELECTRIC |

| Product Series | ||||

| From | ₹ 3,218.58 | ₹ 6,573.55 | ₹ 4,475.18 | ₹ 1,839.74 |

| Days to Ship | 5 Day(s) or more | 10 Day(s) or more | Same day or more | 6 Day(s) or more |

Loading...

Configure

Related Categories to PLC Compatible Batteries

-

- PLC (CPU Units)

- PLC (Power Supply Units)

- PLC (Base Units)

- PLC (Software, Manuals)

- PLC Compatible Cables

- PLC Compatible Batteries

- PLC (Options, Others)

- PLC (Communication Units)

- PLC (Input/Output Units)

- PLC (Analog Units)

- PLC (Memory Units)

- PLC (Motion Controllers)

- PLC (Control Units)

- PLC (Wire-Saving Dedicated Units)

-

FAQ PLC Compatible Batteries

- Question: What are PLC batteries and what applications do they serve in industrial automation?

- Answer: PLC (Programmable Logic Controller) batteries are small, rechargeable batteries that provide backup power to retain memory and program data during power outages. They are crucial in industrial automation to ensure that PLCs maintain their settings and continue operations seamlessly while a power interruption.

- Question: What are the differences between alkaline and lithium-ion PLC batteries?

- Answer: Alkaline and lithium-ion PLC batteries differ in chemistry and performance. Alkaline batteries are cost-effective and readily available, while lithium-ion batteries offer longer life, higher energy density, and better performance in extreme temperatures, making them suitable for critical applications.

- Question: How do I choose the right PLC battery for my application?

- Answer: When selecting a PLC battery, consider factors like voltage, capacity, size, and temperature range. Choose a battery that meets the specific requirements of your PLC model and application, ensuring compatibility for optimal performance.

- Question: What are the best practices for PLC battery maintenance to ensure longevity and reliability?

- Answer: Best practices for PLC battery maintenance include regular checks for corrosion, proper storage, and adhering to recommended charging and discharging cycles. Follow manufacturer guidelines, and replace batteries before their expected lifespan ends to prevent data loss.

- Question: How do I safely dispose of used PLC batteries?

- Answer: Safely dispose of used PLC batteries by recycling them through designated recycling facilities or process. Avoid throwing them in regular trash to prevent environmental harm.

- Question: What are the signs that indicate a PLC battery needs replacement?

- Answer: Signs of a failing PLC battery include low battery alarms, date/time resets, or the PLC not retaining program data during power loss. Regular monitoring and testing help identify these signs early.

- Question: How do I properly store PLC batteries when they're not in use?

- Answer: Store PLC batteries in a cool, dry place away from direct sunlight. Follow the manufacturer's recommendations for optimal storage conditions to preserve battery life.

- Question: Can PLC batteries be recharged, or do they need to be replaced after their lifespan ends?

- Answer: Some PLC batteries are rechargeable, while others are not. Refer to the manufacturer's specifications to determine if the battery in question is rechargeable.

- Question: What are the environmental considerations when using and disposing of PLC batteries?

- Answer: Consider environmental impact by choosing batteries with minimal toxic materials. Proper disposal through recycling ensures that hazardous components are handled responsibly.

- Question: Are there any recent technological advancements in PLC batteries that enhance performance or sustainability?

- Answer: Advancements in PLC batteries focus on improved energy density, longer lifespan, and sustainable materials. Some batteries now incorporate smart technologies for better monitoring and management. Stay updated on industry developments for the latest options.

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy