(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

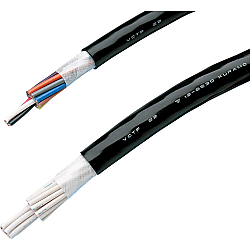

VCTF22 PSE Supported Ductile Vinyl Cabtire Cable

- PSE Law

- Strand Wire

- 300 V

Copy Part Number URL to Clipboard

The part number URL has been copied into your clipboard.-

- Order Qty :

-

-

- Price :

- ---

-

- Total Price :

- ---

-

- Days to ship :

- ---

Select part number to Order Now/ Add to Cart

* Color and softness may vary slightly due to manufacturer changes.

-

- Order Qty. :

-

Check Price / Days to ship

-

- Price :

- ---

-

- Total Price :

- ---

-

- Days to ship :

- ---

-

- Order Qty. :

-

Check Price / Days to ship

-

- Price :

- ---

-

- Total Price :

- ---

-

- Days to ship :

- ---

-

- Order Qty. :

-

Check Price / Days to ship

-

- Price :

- ---

-

- Total Price :

- ---

-

- Days to ship :

- ---

-

- Order Qty. :

-

Check Price / Days to ship

-

- Price :

- ---

-

- Total Price :

- ---

-

- Days to ship :

- ---

Product Description

- VCTF22 PSE Supported Ductile Vinyl Cabtire Cable from MISUMI.

- The VCTF22 series power cable is a generic cable with a rated voltage of 300 V.

- It is a ductile model, and slight variations in color and softness may occur due to manufacturer changes.

- The insulation body is made of PVC, and the sheath of the cable is black in color and made of PVC.

- The cable can operate within a temperature range of 0 to 60 °C.

Specifications

| Model Number | Section Area (mm2) | Number of Cores |

| VCTF22 | 0.5 | 2 |

| 3 | ||

| 4 | ||

| 6 | ||

| 8 | ||

| 10 | ||

| 12 | ||

| 16 | ||

| 20 | ||

| 30 | ||

| 0.75 | 2 | |

| 3 | ||

| 4 | ||

| 6 | ||

| 8 | ||

| 10 | ||

| 12 | ||

| 16 | ||

| 20 | ||

| 30 | ||

| 1.25 | 2 | |

| 3 | ||

| 4 | ||

| 6 | ||

| 8 | ||

| 10 | ||

| 12 | ||

| 16 | ||

| 20 | ||

| 30 | ||

| 2.0 | 2 | |

| 3 | ||

| 4 | ||

| 6 | ||

| 8 | ||

| 10 | ||

| 12 | ||

| 16 | ||

| 20 | ||

| 30 |

Be sure to read the following precautions when you place an order.

* Length in "m" is included in our model numbers. Always specify quantity as number of units, not as meters.

* For the latest information regarding standard unit price, quantity slide unit price, shipment days, etc., refer to the Misumi VONA e-catalog.

*1 Stock products are indicated with T or A in the price column at right.

*2 All unit prices above are per meter.

Unit Price Calculation Method [Formula: Last digits of model number (m) x unit price per meter above]

More Information

Specifications

| Model Number | Section Area (mm2) | Number of Cores | Total Length | AWG Estimated Size *1 | Twisted Structure (See Figure) | Number of Wire Cores | Finished Outer Diameter *4 (mm) | Approximate Mass kg / km | Electrical Properties | Conductor | Insulation | Wire Core Outer Diameter Approx. (mm) | Sheath | Specification | |||||||

| Allowable Current A (30°C) *2 | Conductor Resistance Ω / km (20 °C) | Insulation Properties MΩ km (20 °C) | Withstand Voltage V / Min | Structure Pc / mm | Outer Diameter Approx. (mm) | Plating *3 | Thickness (mm) | Material *3 | Thickness (mm) | Material *3 | |||||||||||

| VCTF22 | 0.5 | 2 | 1 ~ 100 (Specify 1 m Increment) | 20 | Core / Layer Stranding | 2 | 5.8 | 45 | 5 | 37.8 or less | 5 or more | 2000 | 20/0.18 | 0.9 | N/A | 0.5 | PVC | 1.9 | 1.0 | PVC | - |

| 3 | 3 | 6.1 | 55 | 5 | |||||||||||||||||

| 4 | 4 | 6.6 | 65 | 5 | |||||||||||||||||

| 6 | 6 | 7.7 | 90 | 4 | |||||||||||||||||

| 8 | 8 | 8.7 | 100 | 4 | |||||||||||||||||

| 10 | 10 | 9.8 | 120 | 3 | |||||||||||||||||

| 12 | 12 | 10.0 | 140 | 3 | |||||||||||||||||

| 16 | 16 | 11.0 | 175 | 3 | |||||||||||||||||

| 20 | 20 | 12.5 | 210 | 3 | |||||||||||||||||

| 30 | 30 | 14.5 | 305 | 2 | 1.1 | ||||||||||||||||

| 0.75 | 2 | 18 | 2 | 6.6 | 65 | 7 | 25.1 or less | 5 or more | 2000 | 30/0.18 | 1.1 | 0.6 | 2.3 | 1.0 | Compliant with PSE Law | ||||||

| 3 | 3 | 7.0 | 70 | 7 | |||||||||||||||||

| 4 | 4 | 7.6 | 85 | 7 | |||||||||||||||||

| 6 | 6 | 8.9 | 120 | 6 | |||||||||||||||||

| 8 | 8 | 10.0 | 140 | 5 | |||||||||||||||||

| 10 | 10 | 11.5 | 170 | 5 | |||||||||||||||||

| 12 | 12 | 12.0 | 190 | 4 | |||||||||||||||||

| 16 | 16 | 13.5 | 245 | 4 | |||||||||||||||||

| 20 | 20 | 14.5 | 305 | 4 | 1.1 | ||||||||||||||||

| 30 | 30 | 17.5 | 435 | 3 | 1.2 | ||||||||||||||||

| 1.25 | 2 | 16 | 2 | 7.4 | 80 | 12 | 15.1 or less | 5 or more | 2000 | 50/0.18 | 1.5 | 2.7 | 1.0 | ||||||||

| 3 | 3 | 7.8 | 95 | 12 | |||||||||||||||||

| 4 | 4 | 8.5 | 115 | 12 | |||||||||||||||||

| 6 | 6 | 10.0 | 165 | 8 | |||||||||||||||||

| 8 | 8 | 11.5 | 190 | 7 | |||||||||||||||||

| 10 | 10 | 13.0 | 240 | 7 | |||||||||||||||||

| 12 | 12 | 13.5 | 275 | 6 | 1.1 | ||||||||||||||||

| 16 | 16 | 15.0 | 355 | 6 | |||||||||||||||||

| 20 | 20 | 17.0 | 440 | 5 | 1.2 | ||||||||||||||||

| 30 | 30 | 20.0 | 640 | 4 | 1.3 | ||||||||||||||||

| 2.0 | 2 | 14 | 2 | 8.0 | 100 | 17 | 9.79 or less | 5 or more | 2000 | 37/0.26 | 1.8 | 3.0 | 1.0 | ||||||||

| 3 | 3 | 8.5 | 125 | 17 | |||||||||||||||||

| 4 | 4 | 9.2 | 155 | 17 | |||||||||||||||||

| 6 | 6 | 11.0 | 220 | 11 | |||||||||||||||||

| 8 | 8 | 12.5 | 260 | 9 | |||||||||||||||||

| 10 | 10 | 14.5 | 330 | 9 | 1.1 | ||||||||||||||||

| 12 | 12 | 15.0 | 370 | 8 | |||||||||||||||||

| 16 | 16 | 17.0 | 490 | 7 | 1.2 | ||||||||||||||||

| 20 | 20 | 18.5 | 600 | 7 | |||||||||||||||||

| 30 | 30 | 22.5 | 880 | 6 | 1.4 | ||||||||||||||||

*1 The size conversion is for reference only. Refer to the comparison table on >>Click here for details.

*2 The value of allowable current is to be used only as a reference value and is not guaranteed.

*3 How to View Materials

[Plating] Tin... Tin Plated Annealed Copper Wire

[Materials] PVC... Polyvinyl Chloride; PE... Polyethylene-based Material;

P... Polyester-based Material; Fluorine... Various Fluorine Resins; *... Other

*4 For the outer diameter size of cables, wire sheath (coat), etc., refer to "Finished Outer Diameter" in the table above.

Current Reduction Factor

| Ambient Temperature (°C) | 30 | 40 | 50 |

| Current Reduction Factor | 1.00 | 0.82 | 0.58 |

If the ambient temperature is 30 °C or above, the above current reduction factor is multiplied by the allowable current.

(Example) Allowable current value when the ambient temperature is 40°C, double-cored, 0.5mm2: 5 x 0.82 = 4.1 (A)

Wire Core Identification Table

| Number of Core Lines | Wire Core Identification Method |

| 12-core or less | Insulator Coloring Method (Order: Black, White, Red, Green, Yellow, Brown, Blue, Gray, Orange, Purple, Pink, Light Green) |

| 16-core or more | Numbering Method (Numbers 1, 2, 3, 4... are consecutively printed on the surface of the white insulator) |

Basic Information

| Number Of Cores(Core) | 6 |

|---|

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy