(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

Material

Heat Treatment

Surface Treatment

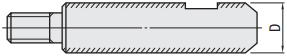

Shaft Dia. D

Length L

B

type

Shaft Fit Tolerance

CAD

Days to Ship

Specification/Dimensions

-

Material

- Steel

- Stainless Steel

- Steel

-

Heat Treatment

- Not Provided

- Induction Hardened

-

Surface Treatment

- Not Provided

- Hard Chrome Plating

-

Shaft Dia. D(Ø)

-

Length L(mm)

-

B(mm)

-

type

- E-PSFAQ

- E-PSFGQ

- E-PSSFAQ

- E-SFAQ

- E-SSFAQ

-

Shaft Fit Tolerance

-

CAD

- 2D

- 3D

Days to Ship

-

- All

- 9 Day(s) or Less

Specify Alterations

Linear Shafts One End Threaded, Thread Size Equal To Shaft Dia

You can add up to 6 items per a category to the compare list.

Brand :

MiSUMi Economy

Part Number :

Copy Part Number URL to Clipboard

The part number URL has been copied into your clipboard.-

- Order Qty :

-

-

- Price :

- ---

-

- Total Price :

- ---

-

- Days to ship :

- ---

Select part number to Order Now/ Add to Cart

Product Overview

Linear guide shaft is a high precision shaft product, which can be used in combination with linear bushing and other bushing products. In addition to excellent abrasion resistance, it offers a variety of alterations.

Dimensional Drawing

L part does not contain an incomplete threaded portion.

L part does not contain an incomplete threaded portion.Specifications Overview

| Type |  Material Material |  Hardness Hardness |  Surface Treatment Surface Treatment | D (mm) | L (mm) | |

| Standard | ||||||

| D Tolerance g7 | D Tolerance f8 | |||||

| E-SFAQ | - | S45C or GCr15 | High Frequency Quenched For effective hardening layer depth, click  Surface Hardness Benchmark Surface Hardness BenchmarkS45C or GCr15 55HRC~ SUS440C or High hardness corrosion resistant steel 53HRC~ | - | 3~30 | 25~1482 |

| E-SSFAQ | - | SUS440C or High hardness corrosion resistant steel | ||||

| E-PSFAQ | - | S45C or GCr15 | Hard Chrome Plated Plating hardness: HV750~ Plating thickness: 3μ or more | |||

| E-PSSFAQ | - | SUS440C or High hardness corrosion resistant steel | ||||

| - | E-PSFGQ | S45C | - | Hard Chrome Plated Plating hardness: HV750~ Plating thickness: 10μ or more | ||

If there are requirements for rust prevention, please give priority to the hard-chrome plated products. Click

If there are requirements for rust prevention, please give priority to the hard-chrome plated products. Click  Rust Prevention Method

Rust Prevention Method For combination with linear bushing, please select high-frequency quenched products.

For combination with linear bushing, please select high-frequency quenched products.Specification Table

| Part Number | 1mm increments | M | (Y) Max. | ||

| Type | D | L | B | ||

| (D Tolerance g7) E-SFAQ E-SSFAQ E-PSFAQ E-PSSFAQ (D Tolerance f8) E-PSFGQ | 3 | 25~197 | 3~15 | 3 | 200 |

| 4 | 25~296 | 4~20 | 4 | 300 | |

| 5 | 25~396 | 4~25 | 5 | 400 | |

| 6 | 25~795 | 5~30 | 6 | 600 | |

| 8 | 25~993 | 7~40 | 8 | 800 | |

| 10 | 25~992 | 8~50 | 10 | 800 | |

| 12 | 25~1191 | 9~60 | 12 | 1000 | |

| 16 | 25~1190 | 10~80 | 16 | 1200 | |

| 20 | 25~1187 | 13~100 | 20 | 1200 | |

| 30 | 25~1482 | 18~150 | 30 | 1500 | |

Priority is given to L dimension, so the effective thread length of B dimension is B- (pitch×2).

Priority is given to L dimension, so the effective thread length of B dimension is B- (pitch×2). O.D. 3, 4 and 5 are not applicable to E-PSFGQ.

O.D. 3, 4 and 5 are not applicable to E-PSFGQ.| D Tolerance | ||

| D | g7 | f8 |

| 3 | -0.002 -0.012 | - |

| 4 | -0.004 -0.016 | |

| 5 | ||

| 6 | -0.010 -0.028 | |

| 8 | -0.005 -0.020 | -0.013 -0.035 |

| 10 | ||

| 12 | -0.006 -0.024 | -0.016 -0.043 |

| 16 | ||

| 20 | -0.007 -0.028 | -0.020 -0.053 |

| 30 | ||

| Coarse thread dimension | |

| M | Thread Pitch |

| 3 | 0.5 |

| 4 | 0.7 |

| 5 | 0.8 |

| 6 | 1.0 |

| 8 | 1.25 |

| 10 | 1.5 |

| 12 | 1.75 |

| 16 | 2.0 |

| 20 | 2.5 |

| 30 | 3.5 |

Alterations

Product Features

Feature 1: Extensively applied in various precision equipment thanks to high precision dimensional tolerance.

Feature 2: Bearing steel (S45C or GCr15) with excellent wear resistance and SUS440C or high hardness corrosion resistant steel are used for high frequency quenching, maintaining the original toughness while enhancing abrasion resistance.

Feature 3: A variety of alterations are available to accommodate different environments.

Feature 4: Usually combined with linear bushing products, achieving excellent linear guiding functionality, and less abrasion even if subject to high-speed reciprocal motion, as compared with general shaft and bushing structure.

Feature 5: The surface treatment of hard-chrome plating is available, achieving excellent anti-rust performance and HV750 plating hardness, as well as less abrasion when used in combination with high-hardness workpieces.

Feature 2: Bearing steel (S45C or GCr15) with excellent wear resistance and SUS440C or high hardness corrosion resistant steel are used for high frequency quenching, maintaining the original toughness while enhancing abrasion resistance.

Feature 3: A variety of alterations are available to accommodate different environments.

Feature 4: Usually combined with linear bushing products, achieving excellent linear guiding functionality, and less abrasion even if subject to high-speed reciprocal motion, as compared with general shaft and bushing structure.

Feature 5: The surface treatment of hard-chrome plating is available, achieving excellent anti-rust performance and HV750 plating hardness, as well as less abrasion when used in combination with high-hardness workpieces.

Precautions

| ②Reduced hardness of machined parts Machining is performed after quenching of base metal. The parts that may be reduced in hardness due to annealing are: -All threaded -All stepped -Tapped: when M≥D/2, tapped double-hole type, hard chrome plated products made of SUS440C or high hardness corrosion resistant steel -Adds wrench flats (SC-WSC-SX) -Adds screw flats (FC-WFC) -Adds V-grooves (VC-WVC) -Except for full length hardened type. |

Only the shaded portion of D part is hard chrome plated. | ③Plating of surface treatment Machining is performed after surface treatment of base metal. No electroplating treatment is applied to the following parts: -Groove part -Threaded part -Tapped part -Wrench slot, V-groove, plane, cut section -The inside of the tube-type guide shaft may rust without hard chrome plating. |

Example of Use

Application Industries

| Medical | Semiconductor | Electronic & Electrical | ||

|  |  | ||

| Smart Phones | Food | Automotive | ||

|  |  |

Related Products

| Linear Bushing Standard Type Straight Type | Bearings With Housings T-Shaped | Shaft Collars (Clamp) | ||

|  |  | ||

| Typical Model: LMU6 | Typical Model: BGHFS6000ZZ-30 | Typical Model: PSCS10-10 | ||

| Advantages: High quality, affordable price, short delivery time | Advantages: Full range, high precision and high quality | Advantages: Matching shaft products, full range |

Related Documents

For anti-rust performance of metal materials and surface treatment, click  Anti-Rust Performance Table.

Anti-Rust Performance Table.

Anti-Rust Performance Table.

Anti-Rust Performance Table.Part Number

- Incomplete part number.

Please use left hand selections to complete a part number.

Loading...

| Part Number |

|---|

| E-PSFAQ3-[25-197/1]-B[3-15/1] |

| E-PSFAQ4-[25-296/1]-B[4-20/1] |

| E-PSFAQ5-[25-396/1]-B[4-25/1] |

| E-PSFAQ8-[25-993/1]-B[7-40/1] |

| E-PSFAQ10-[25-992/1]-B[8-50/1] |

| E-PSFAQ12-[25-1191/1]-B[9-60/1] |

| E-PSFAQ16-[25-1190/1]-B[11-80/1] |

| E-PSFAQ20-[25-1187/1]-B[11-100/1] |

| E-PSSFAQ3-[25-197/1]-B[3-15/1] |

| E-PSSFAQ4-[25-296/1]-B[4-20/1] |

| E-PSSFAQ5-[25-396/1]-B[4-25/1] |

| E-PSSFAQ6-[25-795/1]-B[5-30/1] |

| E-PSSFAQ8-[25-993/1]-B[7-40/1] |

| E-PSSFAQ10-[25-992/1]-B[8-50/1] |

| E-PSSFAQ12-[25-1191/1]-B[9-60/1] |

| E-PSSFAQ16-[25-1190/1]-B[11-80/1] |

| E-PSSFAQ20-[25-1187/1]-B[11-100/1] |

| E-SFAQ3-[25-197/1]-B[3-15/1] |

| E-SFAQ4-[25-296/1]-B[4-20/1] |

| E-SFAQ5-[25-396/1]-B[4-25/1] |

| E-SFAQ8-[25-993/1]-B[7-40/1] |

| E-SFAQ10-[25-992/1]-B[8-50/1] |

| E-SFAQ12-[25-1191/1]-B[9-60/1] |

| E-SFAQ16-[25-1190/1]-B[10-80/1] |

| E-SFAQ20-[25-1187/1]-B[11-100/1] |

| E-SSFAQ3-[25-197/1]-B[3-15/1] |

| E-SSFAQ4-[25-296/1]-B[4-20/1] |

| E-SSFAQ5-[25-396/1]-B[4-25/1] |

| E-SSFAQ6-[25-795/1]-B[5-30/1] |

| E-SSFAQ8-[25-993/1]-B[7-40/1] |

| E-SSFAQ10-[25-992/1]-B[8-50/1] |

| E-SSFAQ12-[25-1191/1]-B[9-60/1] |

| E-SSFAQ16-[25-1190/1]-B[11-80/1] |

| E-SSFAQ20-[25-1187/1]-B[11-100/1] |

| Part Number | Price | Minimum Order Qty. | Volume Discount | Days to Ship | RoHS | Material | Heat Treatment | Surface Treatment | Shaft Dia. D (Ø) | Length L (mm) | Shaft Fit Tolerance | B (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

- | 1 Piece(s) | 9 Day(s) | 10 | [Steel] S45C or GCr15 | Induction Hardened | Hard Chrome Plating | 3 | 25 ~ 197 | g7 | 3 ~ 15 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | [Steel] S45C or GCr15 | Induction Hardened | Hard Chrome Plating | 4 | 25 ~ 296 | g7 | 4 ~ 20 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | [Steel] S45C or GCr15 | Induction Hardened | Hard Chrome Plating | 5 | 25 ~ 396 | g7 | 4 ~ 25 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | [Steel] S45C or GCr15 | Induction Hardened | Hard Chrome Plating | 8 | 25 ~ 993 | g7 | 7 ~ 40 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | [Steel] S45C or GCr15 | Induction Hardened | Hard Chrome Plating | 10 | 25 ~ 992 | g7 | 8 ~ 50 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | [Steel] S45C or GCr15 | Induction Hardened | Hard Chrome Plating | 12 | 25 ~ 1191 | g7 | 9 ~ 60 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | [Steel] S45C or GCr15 | Induction Hardened | Hard Chrome Plating | 16 | 25 ~ 1190 | g7 | 11 ~ 80 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | [Steel] S45C or GCr15 | Induction Hardened | Hard Chrome Plating | 20 | 25 ~ 1187 | g7 | 11 ~ 100 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | [Stainless Steel] Martensite stainless steel | Induction Hardened | Hard Chrome Plating | 3 | 25 ~ 197 | g7 | 3 ~ 15 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | [Stainless Steel] Martensite stainless steel | Induction Hardened | Hard Chrome Plating | 4 | 25 ~ 296 | g7 | 4 ~ 20 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | [Stainless Steel] Martensite stainless steel | Induction Hardened | Hard Chrome Plating | 5 | 25 ~ 396 | g7 | 4 ~ 25 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | [Stainless Steel] Martensite stainless steel | Induction Hardened | Hard Chrome Plating | 6 | 25 ~ 795 | g7 | 5 ~ 30 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | [Stainless Steel] Martensite stainless steel | Induction Hardened | Hard Chrome Plating | 8 | 25 ~ 993 | g7 | 7 ~ 40 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | [Stainless Steel] Martensite stainless steel | Induction Hardened | Hard Chrome Plating | 10 | 25 ~ 992 | g7 | 8 ~ 50 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | [Stainless Steel] Martensite stainless steel | Induction Hardened | Hard Chrome Plating | 12 | 25 ~ 1191 | g7 | 9 ~ 60 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | [Stainless Steel] Martensite stainless steel | Induction Hardened | Hard Chrome Plating | 16 | 25 ~ 1190 | g7 | 11 ~ 80 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | [Stainless Steel] Martensite stainless steel | Induction Hardened | Hard Chrome Plating | 20 | 25 ~ 1187 | g7 | 11 ~ 100 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | [Steel] S45C or GCr15 | Induction Hardened | Not Provided | 3 | 25 ~ 197 | g7 | 3 ~ 15 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | [Steel] S45C or GCr15 | Induction Hardened | Not Provided | 4 | 25 ~ 296 | g7 | 4 ~ 20 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | [Steel] S45C or GCr15 | Induction Hardened | Not Provided | 5 | 25 ~ 396 | g7 | 4 ~ 25 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | [Steel] S45C or GCr15 | Induction Hardened | Not Provided | 8 | 25 ~ 993 | g7 | 7 ~ 40 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | [Steel] S45C or GCr15 | Induction Hardened | Not Provided | 10 | 25 ~ 992 | g7 | 8 ~ 50 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | [Steel] S45C or GCr15 | Induction Hardened | Not Provided | 12 | 25 ~ 1191 | g7 | 9 ~ 60 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | [Steel] S45C or GCr15 | Induction Hardened | Not Provided | 16 | 25 ~ 1190 | g7 | 10 ~ 80 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | [Steel] S45C or GCr15 | Induction Hardened | Not Provided | 20 | 25 ~ 1187 | g7 | 11 ~ 100 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | [Stainless Steel] Martensite stainless steel | Induction Hardened | Not Provided | 3 | 25 ~ 197 | g7 | 3 ~ 15 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | [Stainless Steel] Martensite stainless steel | Induction Hardened | Not Provided | 4 | 25 ~ 296 | g7 | 4 ~ 20 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | [Stainless Steel] Martensite stainless steel | Induction Hardened | Not Provided | 5 | 25 ~ 396 | g7 | 4 ~ 25 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | [Stainless Steel] Martensite stainless steel | Induction Hardened | Not Provided | 6 | 25 ~ 795 | g7 | 5 ~ 30 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | [Stainless Steel] Martensite stainless steel | Induction Hardened | Not Provided | 8 | 25 ~ 993 | g7 | 7 ~ 40 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | [Stainless Steel] Martensite stainless steel | Induction Hardened | Not Provided | 10 | 25 ~ 992 | g7 | 8 ~ 50 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | [Stainless Steel] Martensite stainless steel | Induction Hardened | Not Provided | 12 | 25 ~ 1191 | g7 | 9 ~ 60 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | [Stainless Steel] Martensite stainless steel | Induction Hardened | Not Provided | 16 | 25 ~ 1190 | g7 | 11 ~ 80 | ||

- | 1 Piece(s) | 9 Day(s) | 10 | [Stainless Steel] Martensite stainless steel | Induction Hardened | Not Provided | 20 | 25 ~ 1187 | g7 | 11 ~ 100 |

Loading...

Basic Information

| Basic Shape | Solid | End Shape (Left) | Threaded | End Shape (Right) | No Machining |

|---|---|---|---|---|---|

| Shaft End Perpendicularity | Perpendicularity (0.2) |

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy