(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

Specification/Dimensions

-

Properties

- Standard

- Tooth Surface Cloth Lined

- Backside Cloth Lined

- Both Sides Cloth Lined

-

Belt Type

-

Belt Width(mm)

-

type

- E-LLTBH

- E-LLTBJ

- E-LLTBN

- E-LLTBR

-

CAD

- 2D

- 3D

Days to Ship

-

- All

- 14 Day(s) or Less

Specify Alterations

Jointed Timing Belt T5/T10

You can add up to 6 items per a category to the compare list.

Brand :

MiSUMi Economy

Part Number :

Copy Part Number URL to Clipboard

The part number URL has been copied into your clipboard.-

- Order Qty :

-

-

- Price :

- ---

-

- Total Price :

- ---

-

- Days to ship :

- ---

Select part number to Order Now/ Add to Cart

-

- Order Qty. :

-

-

- Price :

- ---

-

- Total Price :

- ---

-

- Days to ship :

- ---

-

- Order Qty. :

-

-

- Price :

- ---

-

- Total Price :

- ---

-

- Days to ship :

- ---

-

- Order Qty. :

-

-

- Price :

- ---

-

- Total Price :

- ---

-

- Days to ship :

- ---

-

- Order Qty. :

-

-

- Price :

- ---

-

- Total Price :

- ---

-

- Days to ship :

- ---

Jointed timing belts have freely customizable tooth counts and are suitable for long-distance timing transmission.

Available types include standard, tooth-side fabric coated, back-side fabric coated, and double-sided fabric coated.

Double-sided and back-side fabric coated types are ideal for accumulation conveyors.

This is a reference for the use of Jointed timing belts, not a guarantee of actual performance.

This is a reference for the use of Jointed timing belts, not a guarantee of actual performance.

Product Overview

Jointed timing belts have freely customizable tooth counts and are suitable for long-distance timing transmission.

Available types include standard, tooth-side fabric coated, back-side fabric coated, and double-sided fabric coated.

Double-sided and back-side fabric coated types are ideal for accumulation conveyors.

Dimensional Drawing

Specification Overview

■Material

Polyurethane belts may change color over time, but strength etc. will not be affected.

Polyurethane belts may change color over time, but strength etc. will not be affected.

Steel wire core, please avoid tensioning from the back.

Steel wire core, please avoid tensioning from the back.

Operating temperature -20℃~60℃.

Operating temperature -20℃~60℃.

Total length (number of teeth x pitch).

Total length (number of teeth x pitch).

This product is not suitable for gapless timing pulleys.

This product is not suitable for gapless timing pulleys.

Weight is theoretical value and may differ from the actual product.

Weight is theoretical value and may differ from the actual product.

| Type |  Material Material | ||

| ①Main Body | ②Core wire | ③Tooth Fabric | |

| Standard Type | Polyurethane (white) | Steel wire | - |

| Tooth-Side Fabric Coated Type | Nylon canvas (green) | ||

| Back-Side Fabric Coated Type | |||

| Double-sided Fabric Coated Type | |||

| Belt Type | Tooth Pitch | 2θ(°) | H | h | i | Unit weight g/m (width 10mm) |

| Standard | ||||||

| T5 | 5 | 40 | 2.5 | 1.2 | 1.3 | 25 |

| T10 | 10 | 40 | 4.7 | 2.5 | 2.2 | 46 |

Polyurethane belts may change color over time, but strength etc. will not be affected.

Polyurethane belts may change color over time, but strength etc. will not be affected. Steel wire core, please avoid tensioning from the back.

Steel wire core, please avoid tensioning from the back. Operating temperature -20℃~60℃.

Operating temperature -20℃~60℃. Total length (number of teeth x pitch).

Total length (number of teeth x pitch). This product is not suitable for gapless timing pulleys.

This product is not suitable for gapless timing pulleys. Weight is theoretical value and may differ from the actual product.

Weight is theoretical value and may differ from the actual product.Specification Table

■Specifications

The total length is (number of teeth×pitch).

The total length is (number of teeth×pitch).

kgf = N×0.101972

kgf = N×0.101972

| Type | Belt Type | Nominal Belt Width | Number of Teeth Upper limit~Lower limit | Belt Width(mm) | Allowable tension (N) |

| E-LLTBJ (Standard Type) E-LLTBH (Tooth-Side Fabric Coated Type) E-LLTBN (Back-Side Fabric Coated Type) E-LLTBR (Double-Sided Fabric Coated Type) | T5 | 100 | 96~10000 | 10 | 74 |

| 150 | 15 | 99 | |||

| 200 | 20 | 225 | |||

| 250 | 25 | 473 | |||

| T10 | 150 | 52~10000 | 15 | 438 | |

| 200 | 20 | 575 | |||

| 250 | 25 | 875 | |||

| 300 | 30 | 950 | |||

| 400 | 40 | 1125 | |||

| 500 | 50 | 1800 |

The total length is (number of teeth×pitch).

The total length is (number of teeth×pitch). kgf = N×0.101972

kgf = N×0.101972Product Features

Feature 1: The product has embedded steel wire core, which is more cost-effective and has a wider range of applications.

Feature 2: There is no exposed steel wire core on the side of the opening to avoid scratching the opponent or injuring the operator.

Feature 3: Regularly inspect the product to ensure the strength of the joint.

Feature 2: There is no exposed steel wire core on the side of the opening to avoid scratching the opponent or injuring the operator.

Feature 3: Regularly inspect the product to ensure the strength of the joint.

Precautions

■Storage Precautions

①Avoid sunlight.

②Do not use in an environment with direct contact with water, solvents, oil, acid, alkali, ultraviolet rays, ozone, etc.

Especially do not allow oil to adhere to the belt, otherwise it will cause the belt to swell and significantly shorten the service life of the belt.

③Using temperature -20℃~60℃.

④Do not pile up in large quantities or bend forcibly.

⑤Do not place directly on the ground.

⑥Do not allow the belt to come into contact with chemicals.

①Avoid sunlight.

②Do not use in an environment with direct contact with water, solvents, oil, acid, alkali, ultraviolet rays, ozone, etc.

Especially do not allow oil to adhere to the belt, otherwise it will cause the belt to swell and significantly shorten the service life of the belt.

③Using temperature -20℃~60℃.

④Do not pile up in large quantities or bend forcibly.

⑤Do not place directly on the ground.

⑥Do not allow the belt to come into contact with chemicals.

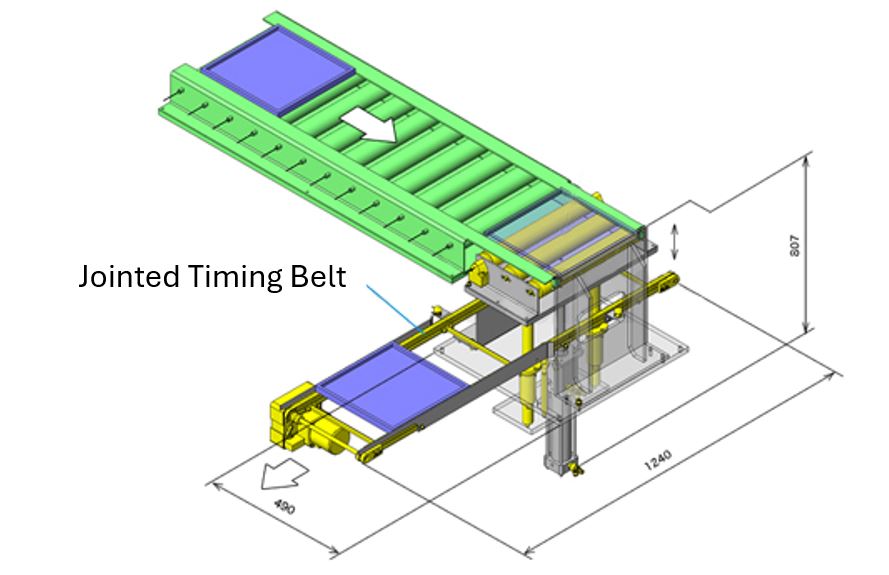

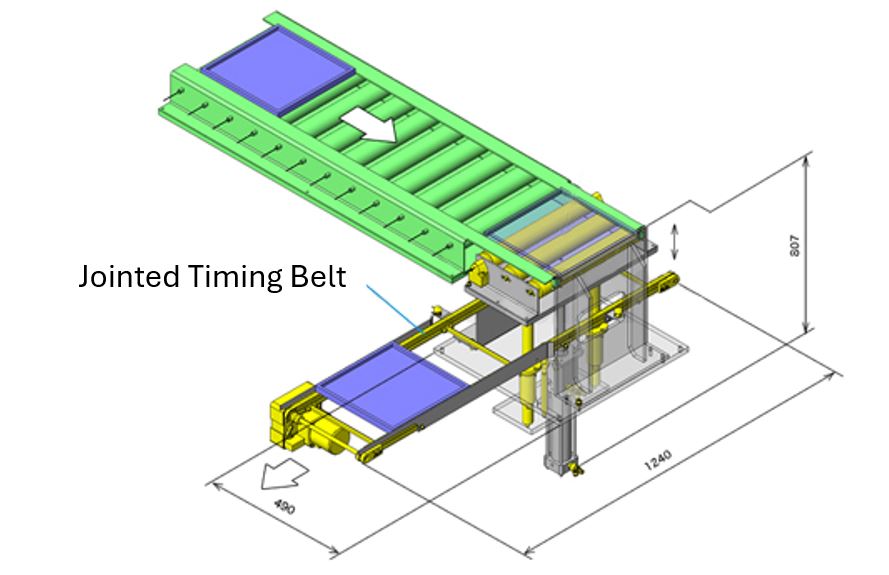

Example of Use

This is a reference for the use of Jointed timing belts, not a guarantee of actual performance.

This is a reference for the use of Jointed timing belts, not a guarantee of actual performance.Equipment Name:

Direct conveyor transfer device with different heights

Functional Description:

The workpiece is transferred by the motor roller, and then the cylinder mechanism is used to move the workpiece down to the conveyor below for transfer. Thus, the purpose of transferring at different heights is achieved.

Direct conveyor transfer device with different heights

Functional Description:

The workpiece is transferred by the motor roller, and then the cylinder mechanism is used to move the workpiece down to the conveyor below for transfer. Thus, the purpose of transferring at different heights is achieved.

Application industry

| Food | Semiconductor | Smartphone | ||

|  |  | ||

| Medical | Electronic appliances | Lithium batteries | ||

|  |  |

Related products

Part Number

- Incomplete part number.

Please use left hand selections to complete a part number.

Loading...

| Part Number |

|---|

| E-LLTBH-T10150-[52-10000/1] |

| E-LLTBH-T10200-[52-10000/1] |

| E-LLTBH-T10250-[52-10000/1] |

| E-LLTBH-T10300-[52-10000/1] |

| E-LLTBH-T10400-[52-10000/1] |

| E-LLTBH-T10500-[52-10000/1] |

| E-LLTBH-T5100-[96-10000/1] |

| E-LLTBH-T5150-[96-10000/1] |

| E-LLTBH-T5200-[96-10000/1] |

| E-LLTBH-T5250-[96-10000/1] |

| E-LLTBJ-T10150-[52-10000/1] |

| E-LLTBJ-T10200-[52-10000/1] |

| E-LLTBJ-T10250-[52-10000/1] |

| E-LLTBJ-T10300-[52-10000/1] |

| E-LLTBJ-T10400-[52-10000/1] |

| E-LLTBJ-T10500-[52-10000/1] |

| E-LLTBJ-T5100-[96-10000/1] |

| E-LLTBJ-T5150-[96-10000/1] |

| E-LLTBJ-T5200-[96-10000/1] |

| E-LLTBJ-T5250-[96-10000/1] |

| E-LLTBN-T10150-[52-10000/1] |

| E-LLTBN-T10200-[52-10000/1] |

| E-LLTBN-T10250-[52-10000/1] |

| E-LLTBN-T10300-[52-10000/1] |

| E-LLTBN-T10400-[52-10000/1] |

| E-LLTBN-T10500-[52-10000/1] |

| E-LLTBN-T5100-[96-10000/1] |

| E-LLTBN-T5150-[96-10000/1] |

| E-LLTBN-T5200-[96-10000/1] |

| E-LLTBN-T5250-[96-10000/1] |

| E-LLTBR-T10150-[52-10000/1] |

| E-LLTBR-T10200-[52-10000/1] |

| E-LLTBR-T10250-[52-10000/1] |

| E-LLTBR-T10300-[52-10000/1] |

| E-LLTBR-T10400-[52-10000/1] |

| E-LLTBR-T10500-[52-10000/1] |

| E-LLTBR-T5100-[96-10000/1] |

| E-LLTBR-T5150-[96-10000/1] |

| E-LLTBR-T5200-[96-10000/1] |

| E-LLTBR-T5250-[96-10000/1] |

| Part Number | Price | Minimum Order Qty. | Volume Discount | Days to Ship | Properties | Belt Type | Belt Width (mm) |

|---|---|---|---|---|---|---|---|

- | 1 Piece(s) | 14 Day(s) | Tooth Surface Cloth Lined | T10 | 15 | ||

- | 1 Piece(s) | 14 Day(s) | Tooth Surface Cloth Lined | T10 | 20 | ||

- | 1 Piece(s) | 14 Day(s) | Tooth Surface Cloth Lined | T10 | 25 | ||

- | 1 Piece(s) | 14 Day(s) | Tooth Surface Cloth Lined | T10 | 30 | ||

- | 1 Piece(s) | 14 Day(s) | Tooth Surface Cloth Lined | T10 | 40 | ||

- | 1 Piece(s) | 14 Day(s) | Tooth Surface Cloth Lined | T10 | 50 | ||

- | 1 Piece(s) | 14 Day(s) | Tooth Surface Cloth Lined | T5 | 10 | ||

- | 1 Piece(s) | 14 Day(s) | Tooth Surface Cloth Lined | T5 | 15 | ||

- | 1 Piece(s) | 14 Day(s) | Tooth Surface Cloth Lined | T5 | 20 | ||

- | 1 Piece(s) | 14 Day(s) | Tooth Surface Cloth Lined | T5 | 25 | ||

- | 1 Piece(s) | 14 Day(s) | Standard | T10 | 15 | ||

- | 1 Piece(s) | 14 Day(s) | Standard | T10 | 20 | ||

- | 1 Piece(s) | 14 Day(s) | Standard | T10 | 25 | ||

- | 1 Piece(s) | 14 Day(s) | Standard | T10 | 30 | ||

- | 1 Piece(s) | 14 Day(s) | Standard | T10 | 40 | ||

- | 1 Piece(s) | 14 Day(s) | Standard | T10 | 50 | ||

- | 1 Piece(s) | 14 Day(s) | Standard | T5 | 10 | ||

- | 1 Piece(s) | 14 Day(s) | Standard | T5 | 15 | ||

- | 1 Piece(s) | 14 Day(s) | Standard | T5 | 20 | ||

- | 1 Piece(s) | 14 Day(s) | Standard | T5 | 25 | ||

- | 1 Piece(s) | 14 Day(s) | Backside Cloth Lined | T10 | 15 | ||

- | 1 Piece(s) | 14 Day(s) | Backside Cloth Lined | T10 | 20 | ||

- | 1 Piece(s) | 14 Day(s) | Backside Cloth Lined | T10 | 25 | ||

- | 1 Piece(s) | 14 Day(s) | Backside Cloth Lined | T10 | 30 | ||

- | 1 Piece(s) | 14 Day(s) | Backside Cloth Lined | T10 | 40 | ||

- | 1 Piece(s) | 14 Day(s) | Backside Cloth Lined | T10 | 50 | ||

- | 1 Piece(s) | 14 Day(s) | Backside Cloth Lined | T5 | 10 | ||

- | 1 Piece(s) | 14 Day(s) | Backside Cloth Lined | T5 | 15 | ||

- | 1 Piece(s) | 14 Day(s) | Backside Cloth Lined | T5 | 20 | ||

- | 1 Piece(s) | 14 Day(s) | Backside Cloth Lined | T5 | 25 | ||

- | 1 Piece(s) | 14 Day(s) | Both Sides Cloth Lined | T10 | 15 | ||

- | 1 Piece(s) | 14 Day(s) | Both Sides Cloth Lined | T10 | 20 | ||

- | 1 Piece(s) | 14 Day(s) | Both Sides Cloth Lined | T10 | 25 | ||

- | 1 Piece(s) | 14 Day(s) | Both Sides Cloth Lined | T10 | 30 | ||

- | 1 Piece(s) | 14 Day(s) | Both Sides Cloth Lined | T10 | 40 | ||

- | 1 Piece(s) | 14 Day(s) | Both Sides Cloth Lined | T10 | 50 | ||

- | 1 Piece(s) | 14 Day(s) | Both Sides Cloth Lined | T5 | 10 | ||

- | 1 Piece(s) | 14 Day(s) | Both Sides Cloth Lined | T5 | 15 | ||

- | 1 Piece(s) | 14 Day(s) | Both Sides Cloth Lined | T5 | 20 | ||

- | 1 Piece(s) | 14 Day(s) | Both Sides Cloth Lined | T5 | 25 |

| Part Number |

|---|

Loading...

Basic Information

| Belt Material | Polyurethane | Belt Shape Type | Trapezoidal Tooth Profile Metric | Belt Shape | Closed End (Weld Jointing) |

|---|---|---|---|---|---|

| Core Wire Material | Steel Cord |

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Frequently asked question (FAQ)

- Question: The connecting belt is connected at both ends. Will the joint be particularly easy to break?

- Answer: The joint of this belt is hot-melt connected. Although the strength is lower than that of the main body, there will be no abnormalities such as breakage under normal tension. However, it is recommended not to bend the joint, otherwise it will cause breakage.

- Question: What kind of belt material is better for working conditions with high cleanliness requirements?

- Answer: It is recommended to use polyurethane belts, which have significantly improved the dust drop compared to rubber belts. At the same time, the tooth surface or double-sided patch type is more recommended, which can more effectively suppress dust drop.

- Question: What are the advantages of double-sided patch type belts compared to standard ones?

- Answer: The double-sided patch type can reduce the friction coefficient and reduce the noise generation.

- Question: The timing belt was damaged after a very short period of use. Is there a problem with the belt quality?

-

Answer:

Timing belt is a standard product, and there are very few individual quality problems in the same batch of products. Customers please refer to

The main causes and corresponding countermeasures of premature damage to check the working conditions of the equipment.

The main causes and corresponding countermeasures of premature damage to check the working conditions of the equipment.

- Not a MISUMI customer yet?

- Register and enjoy 20% Off

- on your 1st order! *

- Download CAD data and product data for more than 12 Mio. products.

- Configure your drawing parts in the MISUMI Online Shop and save time and resources.

- Reduce your process costs with the MISUMI Online Shop.

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy