(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Please note that the MISUMI India offices and warehouses will remain closed from Oct 31st to Nov 3rd due to the Diwali festival.

Please note that the MISUMI Pune office and warehouse will be closed on November 20th due to the state election. - Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

Shaft Bore Dia.1 d1 (or d)

Shaft Bore Dia. 2 d2 (or d)

O.D.

Overall Length

Allowable Torque

Allowable Lateral Misalignment

Max. Rotational Speed

type

Days to Ship

Specification/Dimensions

-

Shaft Bore Dia.1 d1 (or d)(Ø)

-

Shaft Bore Dia. 2 d2 (or d)(Ø)

-

O.D.(Ø)

-

Overall Length(mm)

-

Allowable Torque(N•m)

-

Allowable Lateral Misalignment(mm)

-

Max. Rotational Speed(r/min)

-

type

- E-LMCPW

Days to Ship

-

- All

- 11 Day(s) or Less

Specify Alterations

Double Disc Couplings Clamping Type

You can add up to 6 items per a category to the compare list.

Brand :

MiSUMi Economy

Part Number :

Copy Part Number URL to Clipboard

The part number URL has been copied into your clipboard.-

- Order Qty :

-

-

- Price :

- ---

-

- Total Price :

- ---

-

- Days to ship :

- ---

Select part number to Order Now/ Add to Cart

- CAD Data unavailable

Product Description

This is an economy item, The price is cheaper than the MISUMI standard product.

Product Overview of Flexible Shaft Couplings

Flexible Shaft Couplings is made of several sets of discs (stainless steel sheet) bolted staggered with two coupling halves, each set of discs by several pieces of stacked set.

The Flexible Shaft Couplings relies on the elastic deformation of the disc to compensate for the relative displacement of the two shafts connected, is a high-performance flexible coupling with strong metal components.

It is characterized by compact structure, zero backlash, high strength, long service life, no rotating clearance, unaffected by temperature and oil, acid and alkali resistant and corrosion resistant.

Applicable motor types: Recommended for servo motors, stepper motors and general motors.

The Flexible Shaft Couplings relies on the elastic deformation of the disc to compensate for the relative displacement of the two shafts connected, is a high-performance flexible coupling with strong metal components.

It is characterized by compact structure, zero backlash, high strength, long service life, no rotating clearance, unaffected by temperature and oil, acid and alkali resistant and corrosion resistant.

Applicable motor types: Recommended for servo motors, stepper motors and general motors.

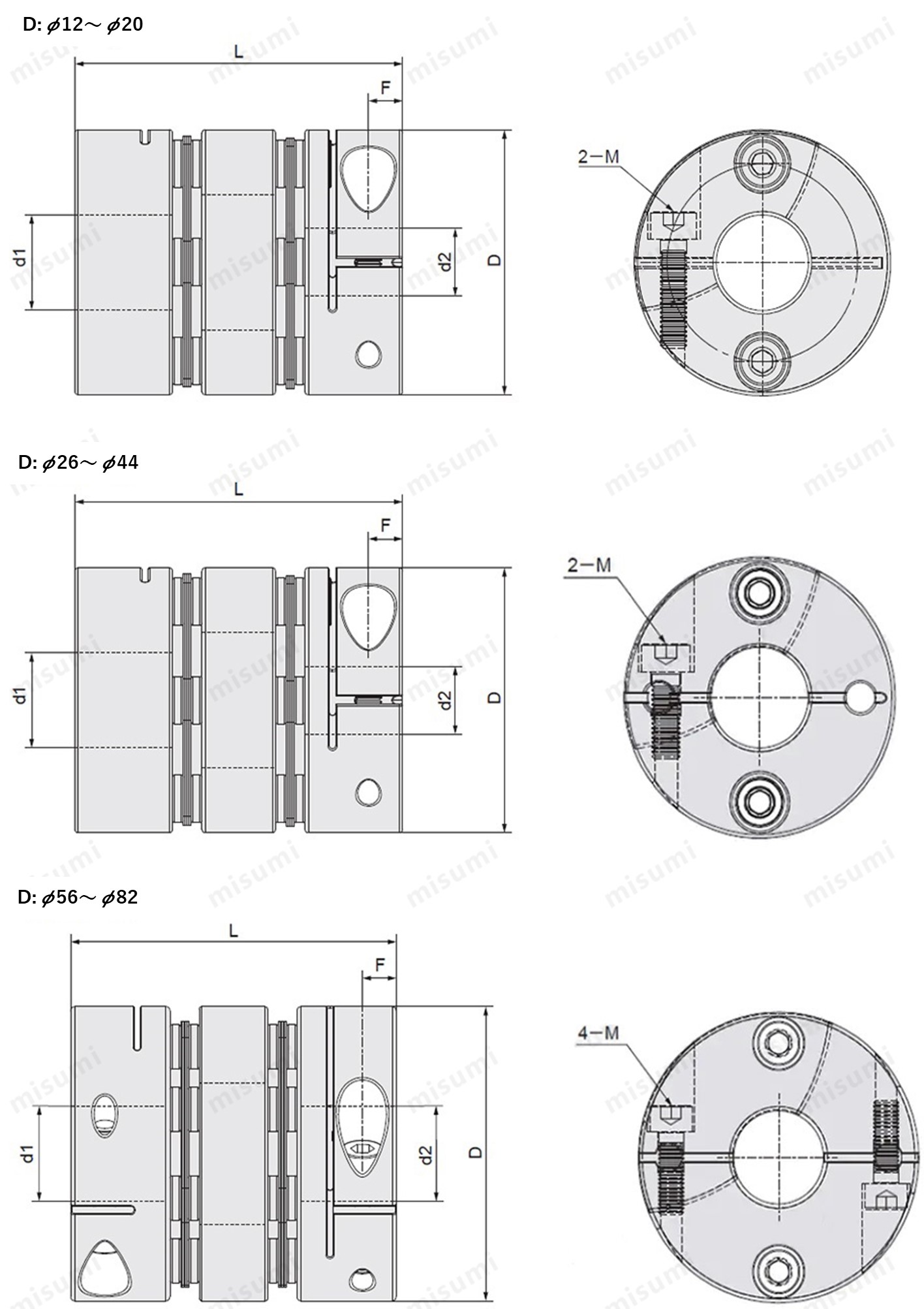

Dimensional Drawing of Flexible Shaft Couplings

Clamping Type

Material table

Material table

| Type | Part |  Material Material |  Surface Treatment Surface Treatment |  Accessory Accessory |

| E-LMCPW | Hub | Aluminum Alloy | Clear Anodize | Hex Socket Clamp Screw |

| Disc | Stainless Steel | - |

Specification Table of Flexible Shaft Couplings

Flexible Shaft Couplings, Please follow the selection steps ~

~  to select the part no. Please specify the shaft holediameter within the range of d1≤d2.

to select the part no. Please specify the shaft holediameter within the range of d1≤d2.

~

~  to select the part no. Please specify the shaft holediameter within the range of d1≤d2.

to select the part no. Please specify the shaft holediameter within the range of d1≤d2.Part No.( Type· Type· D) D) | - |  d1 d1 | - |  d2 d2 |

| E-LMCPW12 | - | 3 | - | 5 |

| E-LMCPW20 | - | 4 | - | 6 |

| Part No. |  d1、 d1、 d2Shaft Hole Dia.(d1≤d2) d2Shaft Hole Dia.(d1≤d2) | ||||||||||||||||||||||||||||||

Type Type |  D D | ||||||||||||||||||||||||||||||

| E-LMCPW | 12 | *3 | *4 | *5 | |||||||||||||||||||||||||||

| 16 | *3 | *4 | *5 | 6 | |||||||||||||||||||||||||||

| 19 | *3 | *4 | *5 | 6 | 6.35 | 7 | 8 | ||||||||||||||||||||||||

| 20 | *3 | *4 | *5 | 6 | 6.35 | 7 | 8 | ||||||||||||||||||||||||

| 26 | *5 | 6 | 6.35 | 7 | 8 | 9 | 9.525 | 10 | 11 | 12 | 14 | ||||||||||||||||||||

| 29 | *5 | 6 | 6.35 | 7 | 8 | 9 | 9.525 | 10 | 11 | 12 | 14 | ||||||||||||||||||||

| 32 | *5 | 6 | 6.35 | 8 | 9 | 9.525 | 10 | 11 | 12 | 12.7 | 14 | 15 | |||||||||||||||||||

| 33 | *5 | 6 | 6.35 | 8 | 9 | 9.525 | 10 | 11 | 12 | 12.7 | 14 | 15 | 16 | ||||||||||||||||||

| 34 | *5 | 6 | 6.35 | 8 | 9 | 9.525 | 10 | 11 | 12 | 12.7 | 14 | 15 | 16 | ||||||||||||||||||

| 39 | 8 | 9 | 9.525 | 10 | 11 | 12 | 12.7 | 14 | 15 | 16 | 17 | 18 | 19 | ||||||||||||||||||

| 44 | 8 | 9 | 9.525 | 10 | 11 | 12 | 12.7 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | ||||||||||||||||

| 56 | 10 | 12 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 25 | 28 | 30 | 32 | ||||||||||||||||

| 68 | 12 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 25 | 28 | 30 | 32 | 35 | 38 | |||||||||||||||

| 82 | 17 | 18 | 19 | 20 | 22 | 24 | 25 | 28 | 30 | 32 | 35 | 38 | 40 | 42 | |||||||||||||||||

d1, d2* size products without keyway holes.

| Part No. | L | F | Clam Screw | Tightening torque (N·m) | Allowable Axial Misalignment (mm) | Static Torsional Spring Constant (N·m/rad) | Maximum Rotational Speed (r/min) | Compensation Coefficient | Mass (g) | ||

| Type | D | M | Tightening torque N.m | ||||||||

| E-LMCPW | 12 | 15.9 | 2.2 | M1.6 | 0.23~0.28 | 0.25 | 0.03 | 133 | 10000 | 1 | 3.7 |

| 16 | 23 | 2.6 | M2 | 0.4~0.5 | 0.6 | 0.05 | 255 | 10000 | 1 | 10 | |

| 19 | 27 | 3.2 | M2.5 | 1 | 1 | 0.12 | 700 | 10000 | 1 | 14 | |

| 20 | 28.8 | 3.2 | M2.5 | 1 | 1 | 0.10 | 550 | 10000 | 1 | 19 | |

| 26 | 35 | 4 | M3 | 1.5 | 2 | 0.15 | 1850 | 10000 | 1 | 37 | |

| 29 | 34.3 | 4 | M3 | 1.5 | 2 | 0.15 | 1200 | 10000 | 1 | 43 | |

| 32 | 41 | 4 | M3 | 1.5 | 6 | 0.17 | 2850 | 10000 | 1 | 67 | |

| 33 | 40 | 4 | M3 | 1.5 | 6 | 0.20 | 1500 | 10000 | 1 | 60 | |

| 34 | 45 | 5 | M4 | 3.5 | 6 | 0.17 | 4050 | 10000 | 1 | 77 | |

| 39 | 50 | 5.2 | M4 | 3.5 | 13 | 0.22 | 9000 | 10000 | 1 | 118 | |

| 44 | 50 | 5.2 | M4 | 3.5 | 15 | 0.22 | 10000 | 10000 | 1 | 144 | |

| 56 | 64 | 6.3 | M5 | 8 | 28 | 0.27 | 25000 | 10000 | 1 | 318 | |

| 68 | 75 | 7.7 | M6 | 13 | 60 | 0.31 | 35000 | 9000 | 1 | 492 | |

| 82 | 98 | 9.8 | M8 | 28 | 100 | 0.55 | 70000 | 8000 | 1 | 1013 | |

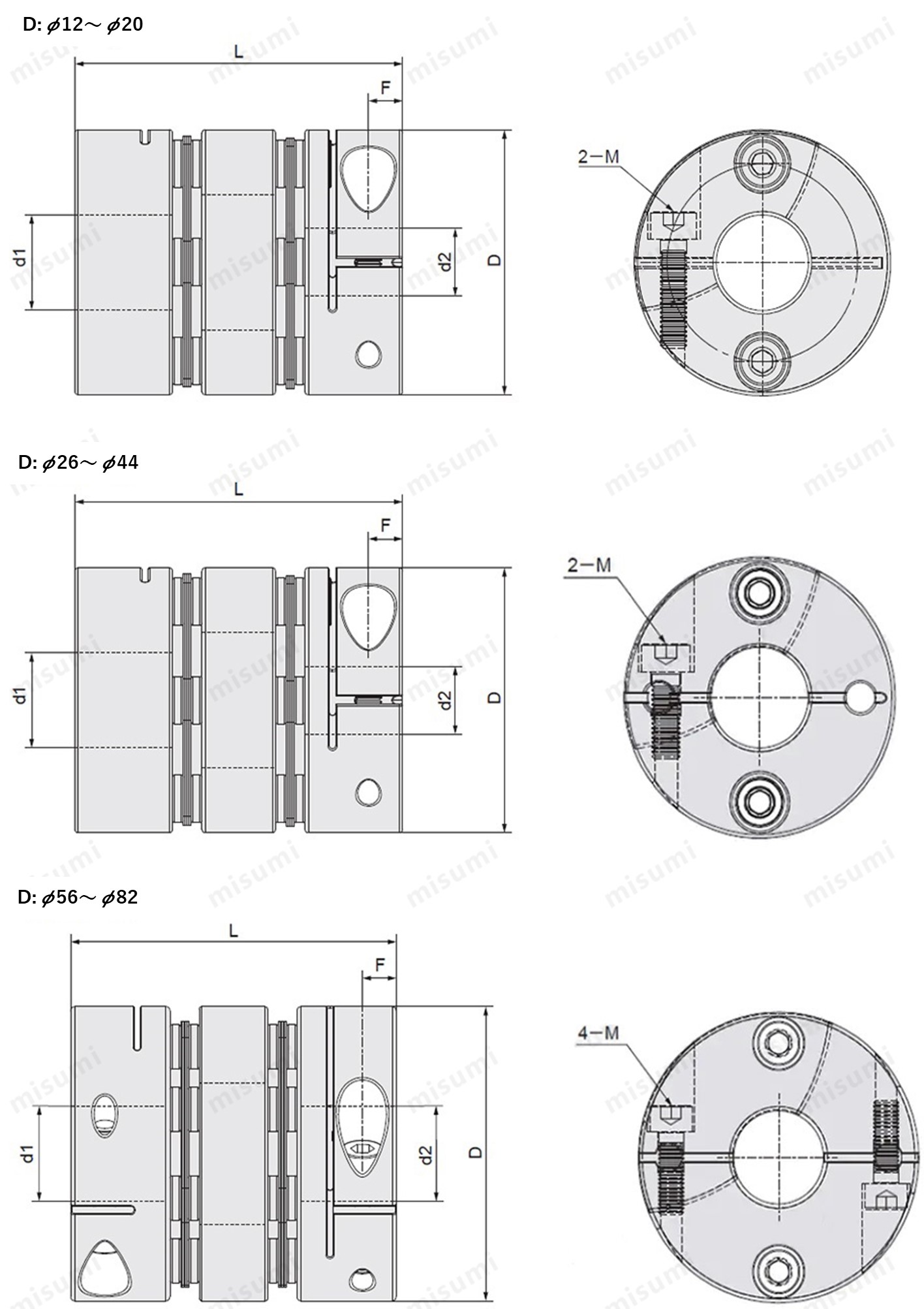

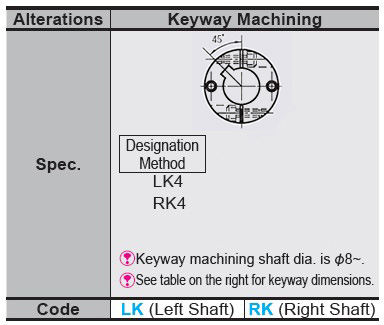

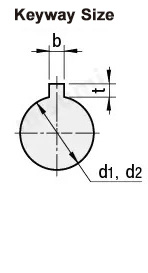

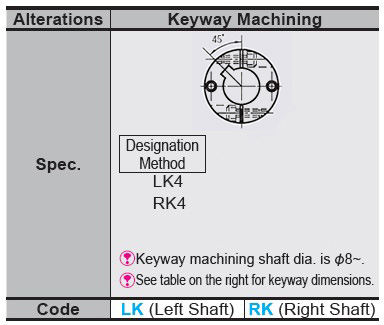

Alterations of Flexible Shaft Couplings

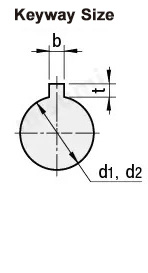

| Shaft Hole Dia. d1 · d2 | b(Keyway Width) | t Keyway Depth | Keyway Nominal Dim. b X h | |

| LK | RK | |||

| 6 ~ 7.9 | 2 | 2 | 1 | 2x2 |

| 8~10 | 3 | 3 | 1.4 | 3x3 |

| 11~12 | 4 | 4 | 1.8 | 4x4 |

| 13~17 | 5 | 5 | 2.3 | 5x5 |

| 18~22 | 6 | 6 | 2.8 | 6x6 |

| 23~30 | 8 | 8 | 3.3 | 8x7 |

| 31~38 | 10 | 10 | 3.3 | 10x8 |

| 39~44 | 12 | 12 | 3.3 | 12x8 |

Product Features of Flexible Shaft Couplings

■Main characteristics of Flexible Shaft Couplings

1. Strong capability to compensate for misalignment of two shafts, offering twice the angular displacement compared to Jaw couplings, lower reactionary forces during radial displacement, high flexibility, and allows for certain axial,radial, and angular displacements.

2. Provides significant vibration damping effects, operates without noise, and wear-free.

3. Can safely operate under conditions of shock and vibration.

4. High transmission efficiency, up to 99.86%, particularly suitable for medium and high-speed, high-power transmission.

5. Simple structure, lightweight, small volume, and convenient for assembly and disassembly. Installation and removal can be done without moving the machine (refers to the type with an intermediate shaft) and does not require lubrication.

6. Can accurately transmit rotational speed, operates without slip, suitable for the transmission of precision machinery.

1. Strong capability to compensate for misalignment of two shafts, offering twice the angular displacement compared to Jaw couplings, lower reactionary forces during radial displacement, high flexibility, and allows for certain axial,radial, and angular displacements.

2. Provides significant vibration damping effects, operates without noise, and wear-free.

3. Can safely operate under conditions of shock and vibration.

4. High transmission efficiency, up to 99.86%, particularly suitable for medium and high-speed, high-power transmission.

5. Simple structure, lightweight, small volume, and convenient for assembly and disassembly. Installation and removal can be done without moving the machine (refers to the type with an intermediate shaft) and does not require lubrication.

6. Can accurately transmit rotational speed, operates without slip, suitable for the transmission of precision machinery.

Example Use of Flexible Shaft Couplings

Precautions of Flexible Shaft Couplings

■Calibration adjustment of Flexible Shaft Couplings

1. The coupling allows transmission of axis deviation, rotation angle and torque, but if the axis deviation exceeds the allowable value, vibration may occur or the lifespan will be drastically reduced. Please be sure to make corrections.

2. Axial deviation includes eccentricity (parallel error of two axes), declination (angular error of two axes), and axial amplitude (axial movement of the axes).

Perform calibration adjustment for the shaft so that the shaft center deviation is below the allowable value specified in the product dimensions and performance table.

3. The axial deviation tolerance values stated in the dimensions and performance tables refer to the situation when one of eccentricity, declination, and axial amplitude occurs individually. If two or moreaxial deviations occur simultaneously, the respective allowable values are reduced by half.

4. Axial deviation not only occurs when assembling the device, but is also a major cause of vibration, thermal expansion, and bearing wear during operation.

It is recommended that the axis deviation be set to less than 1/3 of the allowable value.

1. The coupling allows transmission of axis deviation, rotation angle and torque, but if the axis deviation exceeds the allowable value, vibration may occur or the lifespan will be drastically reduced. Please be sure to make corrections.

2. Axial deviation includes eccentricity (parallel error of two axes), declination (angular error of two axes), and axial amplitude (axial movement of the axes).

Perform calibration adjustment for the shaft so that the shaft center deviation is below the allowable value specified in the product dimensions and performance table.

3. The axial deviation tolerance values stated in the dimensions and performance tables refer to the situation when one of eccentricity, declination, and axial amplitude occurs individually. If two or moreaxial deviations occur simultaneously, the respective allowable values are reduced by half.

4. Axial deviation not only occurs when assembling the device, but is also a major cause of vibration, thermal expansion, and bearing wear during operation.

It is recommended that the axis deviation be set to less than 1/3 of the allowable value.

| Part Number |

|---|

| E-LMCPW12-[3,4,5]-[3,4,5] |

| E-LMCPW16-[3,4,5,6]-[3,4,5,6] |

| E-LMCPW19-[3,4,5,6,6.35,7,8]-[3,4,5,6,6.35,7,8] |

| E-LMCPW20-[3,4,5,6,6.35,7,8]-[3,4,5,6,6.35,7,8] |

| E-LMCPW26-[5,6,6.35,7,8,9,9.525,10,11,12,13,14]-[5,6,6.35,7,8,9,9.525,10,11,12,13,14] |

| E-LMCPW29-[5,6,6.35,7,8,9,9.525,10,11,12,14]-[5,6,6.35,7,8,9,9.525,10,11,12,14] |

| E-LMCPW32-[5,6,6.35,7,8,9,9.525,10,11,12,12.7,14,15]-[5,6,6.35,7,8,9,9.525,10,11,12,12.7,14,15] |

| E-LMCPW33-[5,6,6.35,7,8,9,9.525,10,11,12,12.7,13,14,15,16]-[5,6,6.35,7,8,9,9.525,10,11,12,12.7,13,14,15,16] |

| E-LMCPW34-[5,6,6.35,7,8,9,9.525,10,11,12,12.7,14,15,16]-[5,6,6.35,7,8,9,9.525,10,11,12,12.7,14,15,16] |

| E-LMCPW39-[8,9,9.525,10,11,12,12.7,14,15,16,17,18,19]-[8,9,9.525,10,11,12,12.7,14,15,16,17,18,19] |

| E-LMCPW44-[8,9,9.525,10,11,12,12.7,14,15,16,17,18,19,20,22,24]-[8,9,9.525,10,11,12,12.7,14,15,16,17,18,19,20,22,24] |

| E-LMCPW56-[10,12,14,15,16,17,18,19,20,22,24,25,28,30,32]-[10,12,14,15,16,17,18,19,20,22,24,25,28,30,32] |

| E-LMCPW68-[12,14,15,16,17,18,19,20,22,24,25,28,30,32,35,38]-[12,14,15,16,17,18,19,20,22,24,25,28,30,32,35,38] |

| E-LMCPW82-[17,18,19,20,22,24,25,28,30,32,35,38,40,42]-[17,18,19,20,22,24,25,28,30,32,35,38,40,42] |

| Part Number | Price | Minimum Order Qty. | Volume Discount | Days to Ship | RoHS | Shaft Bore Dia.1 d1 (or d) (Ø) | Shaft Bore Dia. 2 d2 (or d) (Ø) | O.D. (Ø) | Overall Length (mm) | Allowable Torque (N•m) | Allowable Lateral Misalignment (mm) | Max. Rotational Speed (r/min) | Allowable Axial Misalignment (mm) | Moment of Inertia (kg・m2) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

- | 1 Piece(s) | 11 Day(s) | 10 | 3 ~ 5 | 3 ~ 5 | 12 | 15.9 | 0.25 | 0.03 | 10000 | ±0.08 | 7.67×10-8 | ||

- | 1 Piece(s) | 11 Day(s) | 10 | 3 ~ 6 | 3 ~ 6 | 16 | 23 | 0.6 | 0.05 | 10000 | ±0.1 | 3.58×10-7 | ||

- | 1 Piece(s) | 11 Day(s) | 10 | 3 ~ 8 | 3 ~ 8 | 19 | 27 | 1 | 0.12 | 10000 | ±0.18 | 9.1×10-7 | ||

- | 1 Piece(s) | 11 Day(s) | 10 | 3 ~ 8 | 3 ~ 8 | 20 | 28.8 | 1 | 0.1 | 10000 | ±0.20 | 1.1×10-6 | ||

- | 1 Piece(s) | 11 Day(s) | 10 | 5 ~ 14 | 5 ~ 14 | 26 | 35 | 2 | 0.15 | 10000 | ±0.30 | 3.0×10-6 | ||

- | 1 Piece(s) | 11 Day(s) | 10 | 5 ~ 14 | 5 ~ 14 | 29 | 34.3 | 2 | 0.15 | 10000 | ±0.30 | 5.5×10-6 | ||

- | 1 Piece(s) | 11 Day(s) | 10 | 5 ~ 15 | 5 ~ 15 | 32 | 41 | 6 | 0.17 | 10000 | ±0.36 | 7.6×10-6 | ||

- | 1 Piece(s) | 11 Day(s) | 10 | 5 ~ 16 | 5 ~ 16 | 33 | 40 | 6 | 0.2 | 10000 | ±0.40 | 1.1×10-5 | ||

- | 1 Piece(s) | 11 Day(s) | 10 | 5 ~ 16 | 5 ~ 16 | 34 | 45 | 6 | 0.17 | 10000 | ±0.36 | 9.0×10-6 | ||

- | 1 Piece(s) | 11 Day(s) | 10 | 8 ~ 19 | 8 ~ 19 | 39 | 50 | 13 | 0.22 | 10000 | ±0.45 | 3.0×10-5 | ||

- | 1 Piece(s) | 11 Day(s) | 10 | 8 ~ 24 | 8 ~ 24 | 44 | 50 | 15 | 0.22 | 10000 | ±0.54 | 3.8×10-5 | ||

- | 1 Piece(s) | 11 Day(s) | 10 | 10 ~ 32 | 10 ~ 32 | 56 | 64 | 28 | 0.27 | 10000 | ±0.72 | 1.6×10-5 | ||

- | 1 Piece(s) | 11 Day(s) | 10 | 12 ~ 38 | 12 ~ 38 | 68 | 75 | 60 | 0.31 | 9000 | ±0.80 | 2.0×10-4 | ||

- | 1 Piece(s) | 11 Day(s) | 10 | 17 ~ 42 | 17 ~ 42 | 82 | 98 | 100 | 0.55 | 8000 | ±0.80 | 2.5×10-4 |

Loading...

Basic Information

| Series Name | Disc | Application | For Servo Motors / Stepping Motor | Features | High Torsional Rigidity / High Torque Type |

|---|---|---|---|---|---|

| Allowable Misalignment | Angular Misalignment / Eccentricity / Axial Misalignment | Body Material | Aluminum Alloy | Product Category | Coupling Main Body |

| Disc Material | Stainless Steel | Single/Double | Double Disc | Shaft Tightening Method | Fastening Bolt |

| Shaft Hole Shape | Standard |

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Frequently asked question (FAQ)

- Question: What is a coupling?

- Answer: A coupling is a part that connects two different rotating bodies (motor shaft, ball screw, etc.) and aims at transmitting torque. The load of assembly adjustment is reduced by absorbing the axis deviation (lateral misalignment, angular misalignment and axial amplitude) between rotating bodies. And in case of accidental overload, the coupling is destroyed and the rotating bodies are disconnected to protect the expensive power part and the whole device.

- Question: Which disc type coupling is better, single disc type or double disc type?

-

Answer:

Double disc type can absorb angular misalignment and lateral misalignment, but the total length will increase.

Although the total length of the single disc type is short, it is only suitable for applications with narrow space because lateral misalignment is not allowed in the structure.

Special attention should be paid to centering during use. - Question: Abnormal sound or vibration occurs during use of disc type coupling.

-

Answer:

When a servo motor is used, the frequency of the mechanical resonance suppression filter is set as its inherent vibration frequency in the control system to suppress sound and vibration.

When using a stepping motor, the rotational speed can be finely adjusted, or the vibration can be absorbed and suppressed by the high damping rubber type coupling with obvious attenuation effect. - Question: How to achieve the effect of applicable lateral misalignment and angular misalignment in product design?

- Answer: The plate spring formed by the slit allows lateral misalignment, angular misalignment and end play.

- Question: What does the product need for applications of lateral misalignment and angular misalignment?

- Answer: Lateral misalignment, angular misalignment and axial amplitude are all single allowable values. If there are multiple deviations at the same time, the allowable value of each deviation will be reduced to 1/2 of the original value.

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy