(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 6:30 24/11/2024 to 4:30 (IST) 25/11/2024. We apologize for the inconvenience.

- Please note that the MISUMI Pune office and warehouse will be closed on November 20th due to the state election.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

Shaft Bore Dia.1 d1 (or d)

Shaft Bore Dia. 2 d2 (or d)

O.D.

Overall Length

Allowable Torque

Allowable Lateral Misalignment

Max. Rotational Speed

type

Days to Ship

Specification/Dimensions

-

Shaft Bore Dia.1 d1 (or d)(Ø)

-

Shaft Bore Dia. 2 d2 (or d)(Ø)

-

O.D.(Ø)

-

Overall Length(mm)

-

Allowable Torque(N•m)

-

Allowable Lateral Misalignment(mm)

-

Max. Rotational Speed(r/min)

-

type

- E-LMPOC

Days to Ship

-

- All

- 11 Day(s) or Less

Specify Alterations

Oldham Couplings Clamping Type

You can add up to 6 items per a category to the compare list.

Brand :

MiSUMi Economy

Part Number :

Copy Part Number URL to Clipboard

The part number URL has been copied into your clipboard.-

- Order Qty :

-

-

- Price :

- ---

-

- Total Price :

- ---

-

- Days to ship :

- ---

Select part number to Order Now/ Add to Cart

- CAD Data unavailable

Product Description

This is an economy item, The price is cheaper than the MISUMI standard product.

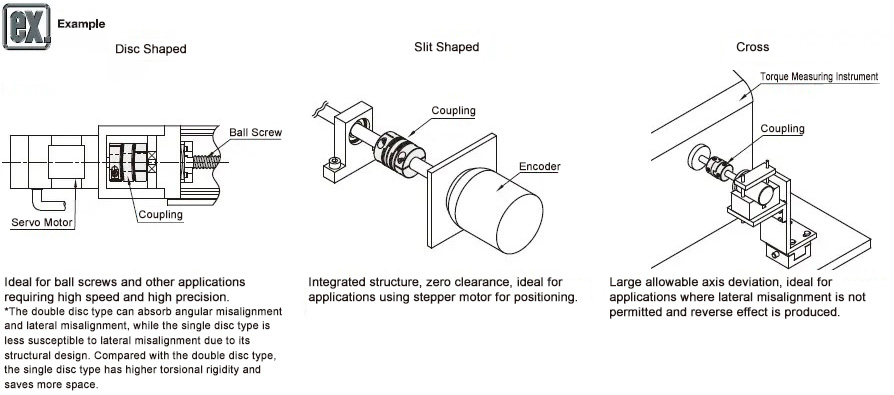

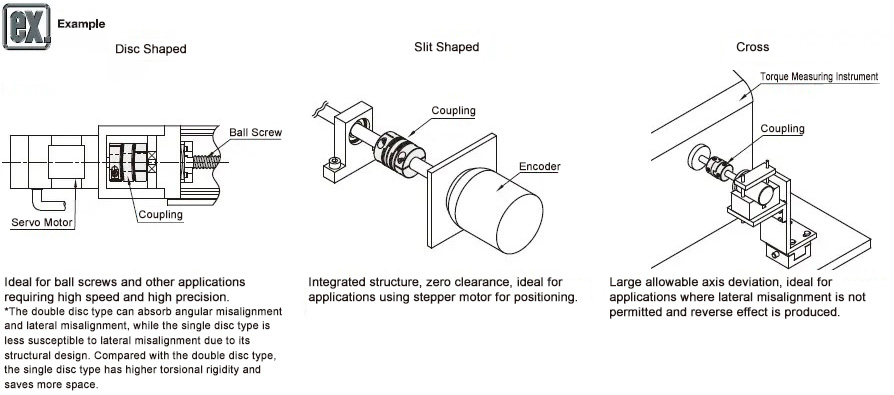

Product Overview of Flexible Shaft Couplings

・Characteristic of Flexible Shaft Couplings

A Flexible Shaft Couplings is a part which purpose is to connect two different rotating bodies (motor shaft, ball screw, etc.) and transmit torque.

Protects equipment by absorbing axial deviations (eccentricity, declination, and axial amplitude) that occur between rotating bodies.

In the event of an overload, the coupling is first damaged and the connection is released to protect the power unit and the entire device.

Protects equipment by absorbing axial deviations (eccentricity, declination, and axial amplitude) that occur between rotating bodies.

In the event of an overload, the coupling is first damaged and the connection is released to protect the power unit and the entire device.

Dimensional Drawing of Flexible Shaft Couplings

Material table of Flexible Shaft Couplings

| Part of Flexible Shaft Couplings | Material of Flexible Shaft Couplings |  Surface Treatment Surface Treatment |  Accessory Accessory |

| Hub | Aluminum Alloy | Clear Anodize | Hex Socket Clamp Screw |

| Spacer | PA66 | - |

Specification Table of Flexible Shaft Couplings

Please follow the selection steps Flexible Shaft Couplings ~

~  to select the part no. Please specify the shaft holediameter within the range of d1≤d2.

to select the part no. Please specify the shaft holediameter within the range of d1≤d2.

If the slip torque is less than the allowable torque, use it below the slip torque.

If the slip torque is less than the allowable torque, use it below the slip torque.

~

~  to select the part no. Please specify the shaft holediameter within the range of d1≤d2.

to select the part no. Please specify the shaft holediameter within the range of d1≤d2.Part No.( Type of Flexible Shaft Couplings· Type of Flexible Shaft Couplings· DL) DL) | - |  d1 d1 | - |  d2 d2 |

| E-LMPOC20L33 | - | 5 | - | 8 |

| E-LMPOC40L50 | - | 10 | - | 18 |

| Part No. |  d1、 d1、 d2Shaft Hole Dia.(d1≤d2) d2Shaft Hole Dia.(d1≤d2) | |||||||||||||||||||||||||||||||

Type of Flexible Shaft Couplings Type of Flexible Shaft Couplings |  D D | L | ||||||||||||||||||||||||||||||

| E-LMPOC | 16 | L29 | 4 | 5 | 6 | 6.35 | ||||||||||||||||||||||||||

| 20 | L33 | 5 | 6 | 6.35 | 7 | 8 | ||||||||||||||||||||||||||

| 25 | L39 | 5 | 6 | 6.35 | 8 | 9 | 9.525 | 10 | 11 | 12 | ||||||||||||||||||||||

| 32 | L45 | 5 | 6 | 8 | 9 | 9.525 | 10 | 11 | 12 | 12.7 | 14 | 15 | 16 | |||||||||||||||||||

| 40 | L50 | 8 | 9 | 9.525 | 10 | 11 | 12 | 14 | 15 | 16 | 17 | 18 | 19 | |||||||||||||||||||

| 44 | L46 | 8 | 9 | 9.525 | 10 | 11 | 12 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | |||||||||||||||||

| 50 | L53 | 10 | 11 | 12.7 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | |||||||||||||||||||

| 50 | L58 | 10 | 11 | 12.7 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | |||||||||||||||||||

| 55 | L57 | 10 | 11 | 12.7 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 25 | 28 | |||||||||||||||||

| 63 | L71 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 25 | 28 | 30 | 32 | ||||||||||||||||||

| 70 | L77 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 25 | 28 | 30 | 32 | 35 | 38 | ||||||||||||||||

If the slip torque is less than the allowable torque, use it below the slip torque.

If the slip torque is less than the allowable torque, use it below the slip torque.| Part No. | F | Clamp Screw | Rated Torque (N·m) | Mass (g) | |||

| Type of Flexible Shaft Couplings | D | L | M | Tightening torque N.m | |||

| E-LMPOC | 16 | L29 | 3 | M2.5 | 1 | 0.7 | 12 |

| 20 | L33 | 3.8 | M2.5 | 1 | 1.2 | 19 | |

| 25 | L39 | 3.9 | M3 | 1.5 | 2 | 35 | |

| 32 | L45 | 4.5 | M4 | 3.5 | 4.5 | 67 | |

| 40 | L50 | 5.5 | M5 | 8 | 9 | 114 | |

| 44 | L46 | 7.8 | M5 | 8 | 12 | 140 | |

| 50 | L53 | 7.5 | M6 | 13 | 19 | 190 | |

| 50L | L58 | 6.3 | M6 | 13 | 19 | 215 | |

| 55 | L57 | 6.3 | M6 | 13 | 25 | 260 | |

| 63 | L71 | 7.8 | M8 | 28 | 33 | 455 | |

| 70 | L77 | 7.7 | M8 | 28 | 56 | 520 | |

Alterations of Flexible Shaft Couplings

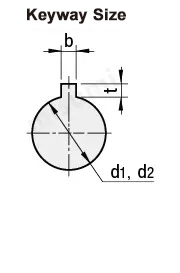

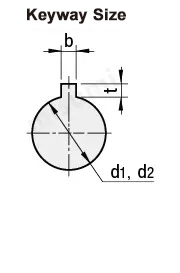

| Flexible Shaft Couplings Dia. d1 · d2 | b(Keyway Width) | t Keyway Depth | Keyway Nominal Dim. b X h | |

| LK | RK | |||

| 8~10 | 3 | 3 | 1.4 | 3x3 |

| 11~12 | 4 | 4 | 1.8 | 4x4 |

| 13~17 | 5 | 5 | 2.3 | 5x5 |

| 18~22 | 6 | 6 | 2.8 | 6x6 |

| 23~30 | 8 | 8 | 3.3 | 8x7 |

| 31~38 | 10 | 10 | 3.3 | 10x8 |

Product Features of Flexible Shaft Couplings

By connecting a cross spacer in the middle of the Flexible Shaft Couplings, it can be freely disassembled and installed.

The spacer uses PA66 and has excellent wear resistance, corrosion resistance, and electrical insulation.

The sliding design compensates for radial and angular deviations more effectively.

The spacer uses PA66 and has excellent wear resistance, corrosion resistance, and electrical insulation.

The sliding design compensates for radial and angular deviations more effectively.

Example Use of Flexible Shaft Couplings

Precautions of Flexible Shaft Couplings

Operating Temperature of Flexible Shaft Couplings: -20℃~80℃. d1、d2

Eccentricity, declination angle and axial amplitude are all allowable values of a single term. If multiple deviations occur at the same time, the allowable value of each deviation is reduced to 1/2 of the original value.

Eccentricity, declination angle and axial amplitude are all allowable values of a single term. If multiple deviations occur at the same time, the allowable value of each deviation is reduced to 1/2 of the original value.

| Part Number |

|---|

| E-LMPOC16L29-[4,5,6,6.35]-[4,5,6,6.35] |

| E-LMPOC20L33-[5,6,6.35,7,8]-[5,6,6.35,7,8] |

| E-LMPOC25L39-[5,6,6.35,8,9,9.525,10,11,12]-[5,6,6.35,8,9,9.525,10,11,12] |

| E-LMPOC32L45-[5,6,6.35,8,9,9.525,10,11,12,12.7,14,15,16]-[5,6,6.35,8,9,9.525,10,11,12,12.7,14,15,16] |

| E-LMPOC40L50-[8,9,9.525,10,11,12,14,15,16,17,18,19]-[8,9,9.525,10,11,12,14,15,16,17,18,19] |

| E-LMPOC44L46-[8,9,9.525,10,11,12,14,15,16,17,18,19,20,22]-[8,9,9.525,10,11,12,14,15,16,17,18,19,20,22] |

| E-LMPOC50L53-[10,11,12.7,14,15,16,17,18,19,20,22,24]-[10,11,12.7,14,15,16,17,18,19,20,22,24] |

| E-LMPOC50L58-[10,11,12.7,14,15,16,17,18,19,20,22,24]-[10,11,12.7,14,15,16,17,18,19,20,22,24] |

| E-LMPOC55L57-[10,11,12.7,14,15,16,17,18,19,20,22,24,25,28]-[10,11,12.7,14,15,16,17,18,19,20,22,24,25,28] |

| E-LMPOC63L71-[14,15,16,17,18,19,20,22,24,25,28,30,32]-[14,15,16,17,18,19,20,22,24,25,28,30,32] |

| E-LMPOC70L77-[14,15,16,17,18,19,20,22,24,25,28,30,32,35,38]-[14,15,16,17,18,19,20,22,24,25,28,30,32,35,38] |

| Part Number | Price | Minimum Order Qty. | Volume Discount | Days to Ship | RoHS | Shaft Bore Dia.1 d1 (or d) (Ø) | Shaft Bore Dia. 2 d2 (or d) (Ø) | O.D. (Ø) | Overall Length (mm) | Allowable Torque (N•m) | Allowable Lateral Misalignment (mm) | Max. Rotational Speed (r/min) | Moment of Inertia (kg・m2) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

- | 1 Piece(s) | 11 Day(s) | 10 | 4 ~ 6.35 | 4 ~ 6.35 | 16 | 29 | 0.7 | 0.8 | 9000 | 3.5×10-7 | ||

- | 1 Piece(s) | 11 Day(s) | 10 | 5 ~ 8 | 5 ~ 8 | 20 | 33 | 1.2 | 1.2 | 7000 | 1.5×10-6 | ||

- | 1 Piece(s) | 11 Day(s) | 10 | 5 ~ 12 | 5 ~ 12 | 25 | 39 | 2 | 1.6 | 6000 | 3.2×10-6 | ||

- | 1 Piece(s) | 11 Day(s) | 10 | 5 ~ 16 | 5 ~ 16 | 32 | 45 | 4.5 | 2 | 4800 | 1.5×10-5 | ||

- | 1 Piece(s) | 11 Day(s) | 10 | 8 ~ 19 | 8 ~ 19 | 40 | 50 | 9 | 2.4 | 3600 | 4.2×10-5 | ||

- | 1 Piece(s) | 11 Day(s) | 10 | 8 ~ 22 | 8 ~ 22 | 44 | 46 | 12 | 2.5 | 3500 | 4.5×10-5 | ||

- | 1 Piece(s) | 11 Day(s) | 10 | 10 ~ 24 | 10 ~ 24 | 50 | 53 | 19 | 2.6 | 3000 | 1.0×10-4 | ||

- | 1 Piece(s) | 11 Day(s) | 10 | 10 ~ 24 | 10 ~ 24 | 50 | 58 | 19 | 3 | 3000 | 1.1×10-4 | ||

- | 1 Piece(s) | 11 Day(s) | 10 | 10 ~ 28 | 10 ~ 28 | 55 | 57 | 25 | 3.2 | 3000 | 1.3×10-5 | ||

- | 1 Piece(s) | 11 Day(s) | 10 | 14 ~ 32 | 14 ~ 32 | 63 | 71 | 33 | 3 | 2550 | 3.5×10-4 | ||

- | 1 Piece(s) | 11 Day(s) | 10 | 14 ~ 38 | 14 ~ 38 | 70 | 77 | 56 | 3.5 | 2500 | 4.1×10-4 |

Loading...

Basic Information

| Series Name | Oldham | Application | Standard / For Servo Motors / Stepping Motor | Features | High Torsional Rigidity / High Torque Type |

|---|---|---|---|---|---|

| Body Material | Aluminum Alloy | Allowable Angular Misalignment(deg) | 3 | Product Category | Coupling Main Body |

| Buffer Material | Nylon | Allowable Axial Misalignment(mm) | ±0.2 | Shaft Tightening Method | Fixing Bolt |

| Shaft Hole Shape | Standard | Spacer Material | PA66 |

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Frequently asked question (FAQ)

- Question: What is a coupling?

- Answer: A coupling is a part that connects two different rotating bodies (motor shaft, ball screw, etc.) and aims at transmitting torque. The load of assembly adjustment is reduced by absorbing the axis deviation (lateral misalignment, angular misalignment and axial amplitude) between rotating bodies. And in case of accidental overload, the coupling is destroyed and the rotating bodies are disconnected to protect the expensive power part and the whole device.

- Question: Is there any reference available for lateral misalignment and angular misalignment of the product?

- Answer: Lateral misalignment, angular misalignment and axial amplitude are all single allowable values. If there are multiple deviations at the same time, the allowable value of each deviation will be reduced to 1/2 of the original value.

- Question: What are the product features?

- Answer: The middle of the coupling is connected with a cross slider, which can be disassembled freely. Large radial and angular deviations are allowed.

- Question: Is there a keyway machining for the inner hole of the product?

- Answer: Additional keyways can be machined on the product body. Please refer to MISUMI manual and website.

- Question: Do I need to assemble the product myself when it arrives?

- Answer: The products are shipped from different places and may arrive in bulk, so please just put them together yourself.

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy