(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Due to an increase in demand, the lead time of some of the electrical items from our eCatalogue has increased abnormally and may cause delays in delivery or order suspension. We apologize for the inconvenience and appreciate your kind understanding. Once the supply will get normalized, we will update the same.

Specification/Dimensions

-

Lead

-

Effective Stroke(mm)

-

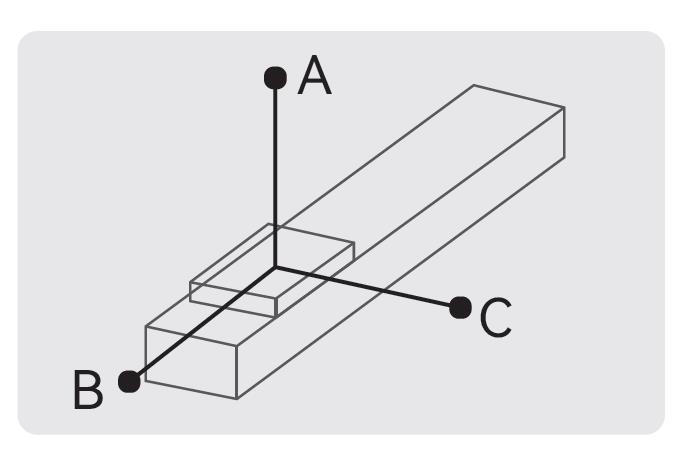

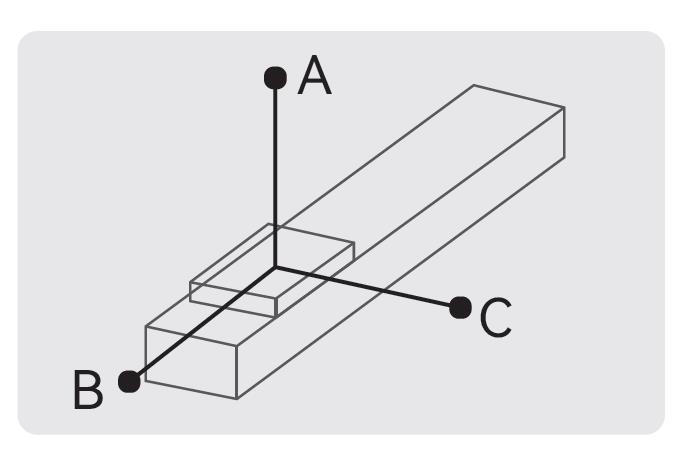

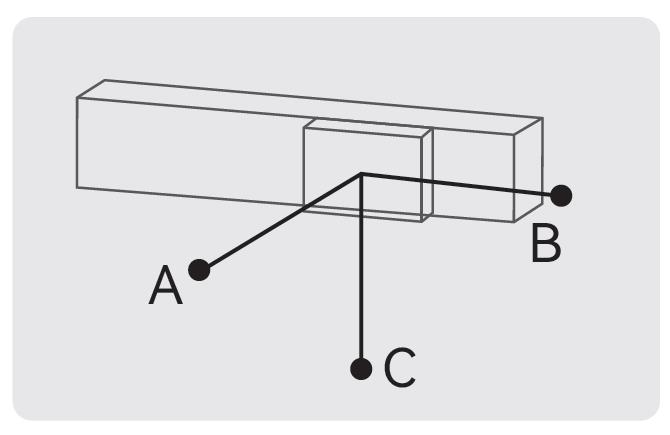

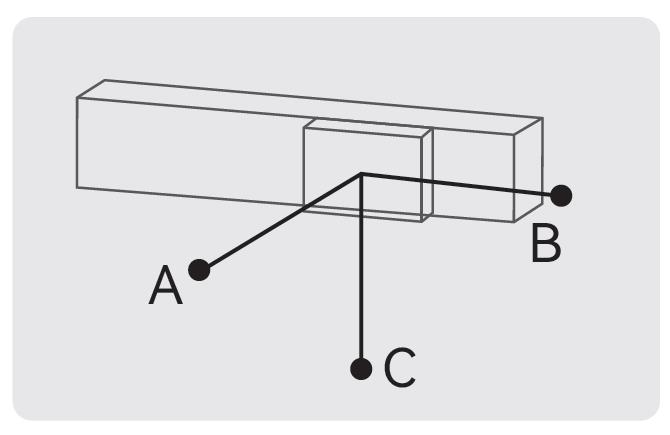

Motor Position

- BC Motor Direct Connection

- BL Motor On Left Side

- BM Motor On Lower Side

- BR Motor On Right Side

-

Motor Brand & Power

-

Sensor Position

- C Motor Side

- D Motor Opposite Side

-

type

- E-MCT8

-

CAD

- 2D

- 3D

Days to Ship

-

- All

- 13 Day(s) or Less

Specify Alterations

Single Axis Robots E-MCT8, Guide Built in Type, Fully-Sealed Type(For Clean Environment)

You can add up to 6 items per a category to the compare list.

Brand :

MiSUMi Economy

Part Number :

Copy Part Number URL to Clipboard

The part number URL has been copied into your clipboard.-

- Order Qty :

-

-

- Price :

- ---

-

- Total Price :

- ---

-

- Days to ship :

- ---

Select part number to Order Now/ Add to Cart

(i)

Caution

- The product does not come with a driver or motor, which must be purchased separately

- The product comes with a sensor kit, which is unnecessary to select

Product Description

Economy series Aluminum Alloy Embedded Actuators E-MCT8 Series product only includes the main unit, not the driver, which must be purchased separately. The product comes with a sensor kit, for which only mounting direction needs to be selected.

Product Overview

Economy series Aluminum Alloy Embedded Actuators are transmission devices integrating ball screws and embedded guides, which are indispensable for the production process.

Aluminum alloy base is directly embedded in the steel rail and then ground to improve travel height and straightness accuracy up to ±0.02.

Small size and easy assembly

Aluminum alloy base is directly embedded in the steel rail and then ground to improve travel height and straightness accuracy up to ±0.02.

Small size and easy assembly

Product Features

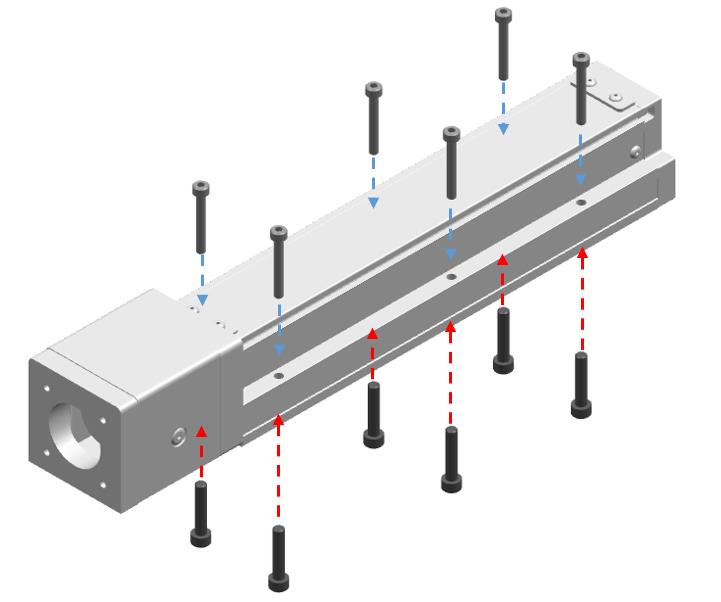

1. Simple design and installation

2. Small size and light weight

3. High precision ±0.01

4. High rigidity

5. Low noise

6. Complete set of fittings

2. Small size and light weight

3. High precision ±0.01

4. High rigidity

5. Low noise

6. Complete set of fittings

Dimensional Drawing

| Components | Body | Embedded Guide | Screw | Nut | Slide Block | Cover |

Material Material | Aluminum Alloy | Bearing Steel | Carbon Steel | Alloy Steel | Aluminum Alloy | Stainless Steel |

Surface Treatment Surface Treatment | Anodized | - | - | - | Anodized | - |

Dimension (mm), Mass (kg)

| Effective Stroke | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 | 1100 |

| L | 328 | 378 | 428 | 478 | 528 | 578 | 628 | 678 | 728 | 778 | 828 | 878 | 928 | 978 | 1028 | 1078 | 1128 | 1178 | 1228 | 1278 | 1328 | 1378 |

| A | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 |

| M | 1 | 1 | 2 | 2 | 3 | 3 | 4 | 4 | 5 | 5 | 6 | 6 | 7 | 7 | 8 | 8 | 9 | 9 | 10 | 10 | 11 | 11 |

| N | 6 | 6 | 8 | 8 | 10 | 10 | 12 | 12 | 14 | 14 | 16 | 16 | 18 | 18 | 20 | 20 | 22 | 22 | 24 | 24 | 26 | 26 |

| P | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 | 1100 |

| KG | 3.91 | 4.29 | 4.70 | 5.00 | 5.35 | 5.68 | 6.00 | 6.35 | 6.64 | 6.97 | 7.41 | 7.71 | 8.12 | 8.41 | 8.65 | 8.96 | 9.37 | 9.62 | 10.01 | 10.28 | 10.70 | 11.12 |

Dimension (mm), Mass (kg)

| Effective Stroke | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 | 1100 |

| L | 314.5 | 364.5 | 414.5 | 464.5 | 514.5 | 564.5 | 614.5 | 664.5 | 714.5 | 764.5 | 814.5 | 864.5 | 914.5 | 964.5 | 1014.5 | 1064.5 | 1114.5 | 1164.5 | 1214.5 | 1264.5 | 1314.5 | 1364.5 |

| A | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 |

| M | 0 | 0 | 1 | 1 | 2 | 2 | 3 | 3 | 4 | 4 | 5 | 5 | 6 | 6 | 7 | 7 | 8 | 8 | 9 | 9 | 10 | 10 |

| N | 4 | 4 | 6 | 6 | 8 | 8 | 10 | 10 | 12 | 12 | 14 | 14 | 16 | 16 | 18 | 18 | 20 | 20 | 22 | 22 | 24 | 24 |

| P | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 | 1100 |

| KG | 3.95 | 4.33 | 4.74 | 5.09 | 5.39 | 5.72 | 6.04 | 6.39 | 6.68 | 7.01 | 7.45 | 7.75 | 8.16 | 8.45 | 8.69 | 9.00 | 9.41 | 9.66 | 10.08 | 10.32 | 10.74 | 11.16 |

Dimension (mm), Mass (kg)

| Effective Stroke | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 | 1100 |

| L | 314.5 | 364.5 | 414.5 | 464.5 | 514.5 | 564.5 | 614.5 | 664.5 | 714.5 | 764.5 | 814.5 | 864.5 | 914.5 | 964.5 | 1014.5 | 1064.5 | 1114.5 | 1164.5 | 1214.5 | 1264.5 | 1314.5 | 1364.5 |

| A | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 |

| M | 1 | 1 | 2 | 2 | 3 | 3 | 4 | 4 | 5 | 5 | 6 | 6 | 7 | 7 | 8 | 8 | 9 | 9 | 10 | 10 | 11 | 11 |

| N | 6 | 6 | 8 | 8 | 10 | 10 | 12 | 12 | 14 | 14 | 16 | 16 | 18 | 18 | 20 | 20 | 22 | 22 | 24 | 24 | 26 | 26 |

| P | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 | 1100 |

| KG | 3.95 | 4.33 | 4.74 | 5.09 | 5.39 | 5.72 | 6.04 | 6.39 | 6.68 | 7.01 | 7.45 | 7.75 | 8.16 | 8.45 | 8.69 | 9.00 | 9.41 | 9.66 | 10.08 | 10.32 | 10.74 | 11.16 |

Dimension (mm), Mass (kg)

| Effective Stroke | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 | 1100 |

| L | 314.5 | 364.5 | 414.5 | 464.5 | 514.5 | 564.5 | 614.5 | 664.5 | 714.5 | 764.5 | 814.5 | 864.5 | 914.5 | 964.5 | 1014.5 | 1064.5 | 1114.5 | 1164.5 | 1214.5 | 1264.5 | 1314.5 | 1364.5 |

| A | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 |

| M | 1 | 1 | 2 | 2 | 3 | 3 | 4 | 4 | 5 | 5 | 6 | 6 | 7 | 7 | 8 | 8 | 9 | 9 | 10 | 10 | 11 | 11 |

| N | 6 | 6 | 8 | 8 | 10 | 10 | 12 | 12 | 14 | 14 | 16 | 16 | 18 | 18 | 20 | 20 | 22 | 22 | 24 | 24 | 26 | 26 |

| P | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 | 1100 |

| KG | 3.95 | 4.33 | 4.74 | 5.09 | 5.39 | 5.72 | 6.04 | 6.39 | 6.68 | 7.01 | 7.45 | 7.75 | 8.16 | 8.45 | 8.69 | 9.00 | 9.41 | 9.66 | 10.08 | 10.32 | 10.74 | 11.16 |

Specification Table

■Basic Specifications

| Drive Method | Ball Screw | |

| Ball Screw | Accuracy grade | C7 |

| O.D. (mm) | Φ16 | |

| Body width (mm) | 82 | |

| Drive Power (W) | 200/400 | |

| Operating Environment | Clean | |

| Part Number |  Lead (mm) Lead (mm) |  Stroke Stroke(50millimeters increments) |  Motor Position |  Motor Brand |  Motor Power |  Sensor Position | Repetitive Positioning Accuracy (mm) | Max. Payload (kg) | Max. Speed (mm/sec) | Rated Thrust (N) | ||

Type Type | Horizontal Use | Vertical Use | 200W | 400W | ||||||||

| E-MCT8 | 5 | 50~1100 | BC (Motor Direct Connection) BM (Motor On Lower Side) BL (Motor On Left Side) BR (Motor On Right Side) | M (Mitsubishi) P (Panasonic) Y (Yaskawa) T (Delta Electronics) Z (Prepared by Customer) | 20 (200W) 40 (400W) | C (External Motor Side) D (External Motor Opposite Side) | ±0.01 | 50 | 15 | 250 | 683 | 1388 |

| 10 | 30 | 8 | 500 | 341 | 694 | |||||||

| 20 | 18 | 3 | 1000 | 174 | 347 | |||||||

A motor is not included to this product and it must be purchased separately.

A motor is not included to this product and it must be purchased separately. When the stroke exceeds 600mm, ball screw resonance will occur. In this case, reduce the movement speed.

When the stroke exceeds 600mm, ball screw resonance will occur. In this case, reduce the movement speed. Select a motor with brake for vertical use.

Select a motor with brake for vertical use. When Z is selected as the motor brand (prepared by customer), please provide the motor model and power when placing an order. (If necessary, provide the motor mounting dimensions)

When Z is selected as the motor brand (prepared by customer), please provide the motor model and power when placing an order. (If necessary, provide the motor mounting dimensions) As the drawings are schematic diagrams, please confirm the detailed dimensions according to CAD data.

As the drawings are schematic diagrams, please confirm the detailed dimensions according to CAD data.| Part Number | Lead (mm) | Motor Power (W) | Max. Movement Speed (mm/sec) | |||||||||||||||||||||

| 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 | 1100 | |||

| E-MCT8 | 5 | 200 | 250 | 225 | 200 | 175 | 150 | 125 | 100 | 75 | ||||||||||||||

| 10 | 500 | 450 | 400 | 350 | 300 | 250 | 200 | 150 | ||||||||||||||||

| 20 | 1000 | 900 | 800 | 700 | 600 | 500 | 400 | 300 | ||||||||||||||||

| 5 | 400 | 250 | 225 | 200 | 175 | 150 | 125 | 100 | 75 | |||||||||||||||

| 10 | 500 | 450 | 400 | 350 | 300 | 250 | 200 | 150 | ||||||||||||||||

| 20 | 1000 | 900 | 800 | 700 | 600 | 500 | 400 | 300 | ||||||||||||||||

Values in the table are reference values calculated according to the critical speed and DN value of the ball screw.

Values in the table are reference values calculated according to the critical speed and DN value of the ball screw. Values in the table are maximum safety speeds available for each stroke. As ball screws may resonate at longer strokes, such conditions as abnormal sound and vibration may occur when operating at the maximum speed. Therefore, the moving speed should be reduced appropriately.

Values in the table are maximum safety speeds available for each stroke. As ball screws may resonate at longer strokes, such conditions as abnormal sound and vibration may occur when operating at the maximum speed. Therefore, the moving speed should be reduced appropriately.■Accessories

Accessories Accessories | Accessory Name | Part Number | Quantity | |||

| Sensor | C-MSX674N-2M | 3 | ||||

| Motor connection method | BC | Coupling (mm) | 10*14(*11) Motor Side (200W) | 10x14 Motor Side (400W) | 1 | |

| BL/BR/BM | Timing Pulley | S3M-36 Teeth-14 (combination) | 1 | |||

| Timing Pulleys | S3M-36 Teeth-10 (combination) | 1 | ||||

| Timing Belt | S3M-258-15 | 1 | ||||

Parameters of Use

■Sensing Line Wiring Diagram

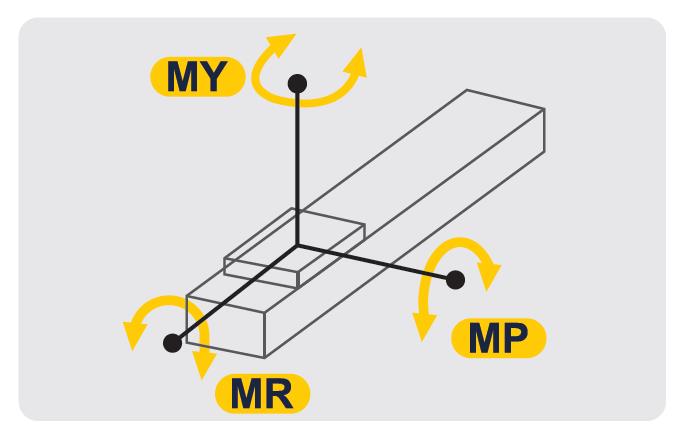

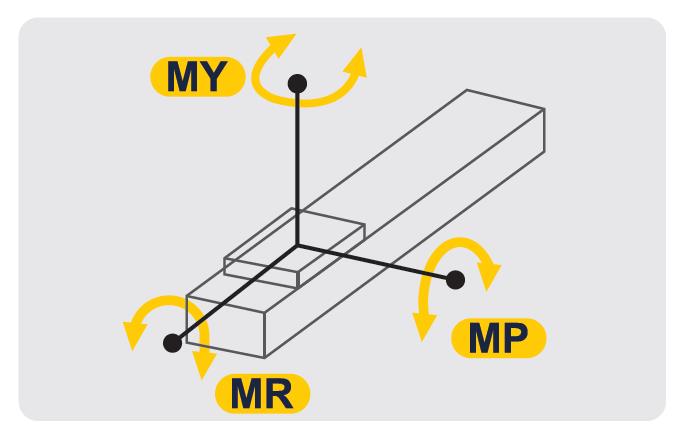

■Allowable Load Torque Table

■Allowable Load Torque Table

Unit (mm)

| Horizontal Installation | A | B | C | |

| Lead 5 | 20kg | 1560 | 153 | 237 |

| 35kg | 890 | 81 | 126 | |

| 50kg | 550 | 53 | 82 | |

| Lead 10 | 10kg | 1730 | 286 | 412 |

| 20kg | 839 | 136 | 196 | |

| 30kg | 541 | 86 | 124 | |

| Lead 20 | 6kg | 1213 | 403 | 493 |

| 9kg | 800 | 264 | 323 | |

| 18kg | 592 | 194 | 238 | |

Unit (mm)

| Wall Installation | A | B | C | |

| Lead 5 | 20kg | 214 | 153 | 1435 |

| 35kg | 113 | 81 | 845 | |

| 50kg | 74 | 53 | 506 | |

| Lead 10 | 10kg | 370 | 286 | 1400 |

| 20kg | 176 | 136 | 800 | |

| 30kg | 112 | 86 | 495 | |

| Lead 20 | 6kg | 444 | 403 | 760 |

| 9kg | 292 | 264 | 277 | |

| 18kg | 214 | 194 | 544 | |

Unit (mm)

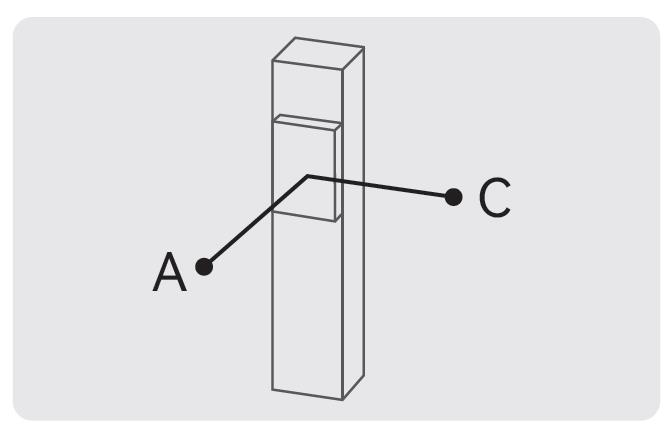

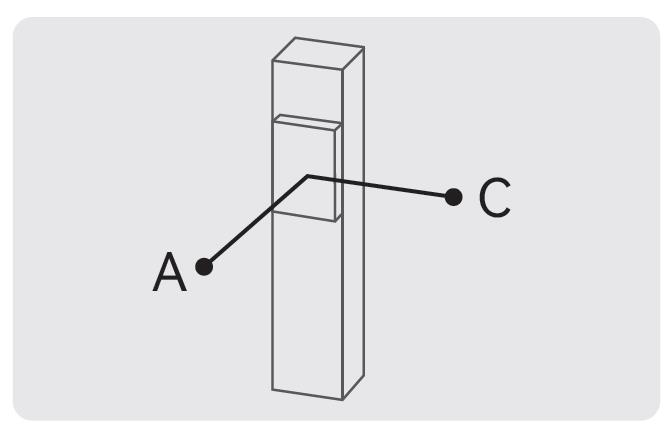

■Static Allowable Load Inertia

| Vertical Installation | A | C | |

| Lead 5 | 10kg | 331 | 331 |

| 15kg | 220 | 220 | |

| Lead 10 | 5kg | 589 | 589 |

| 8kg | 368 | 368 | |

| Lead 20 | 3kg | 935 | 935 |

■Static Allowable Load Inertia

Unit (mm)

■List of Recommended Servo Motors

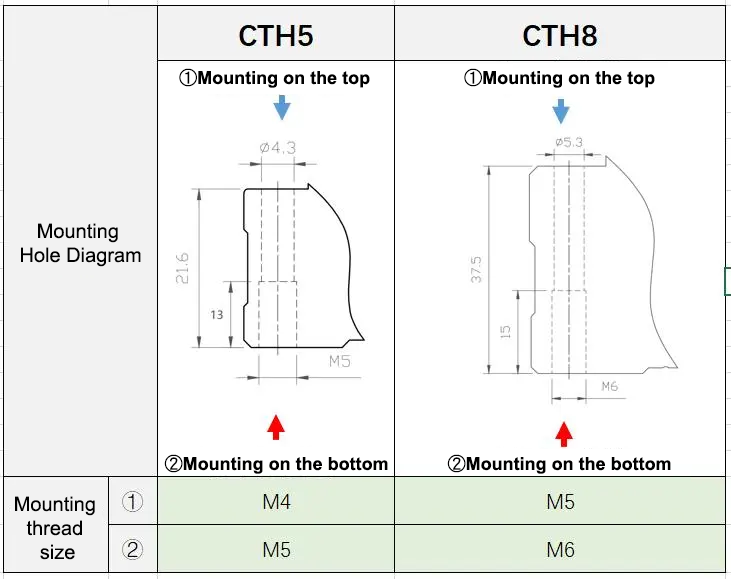

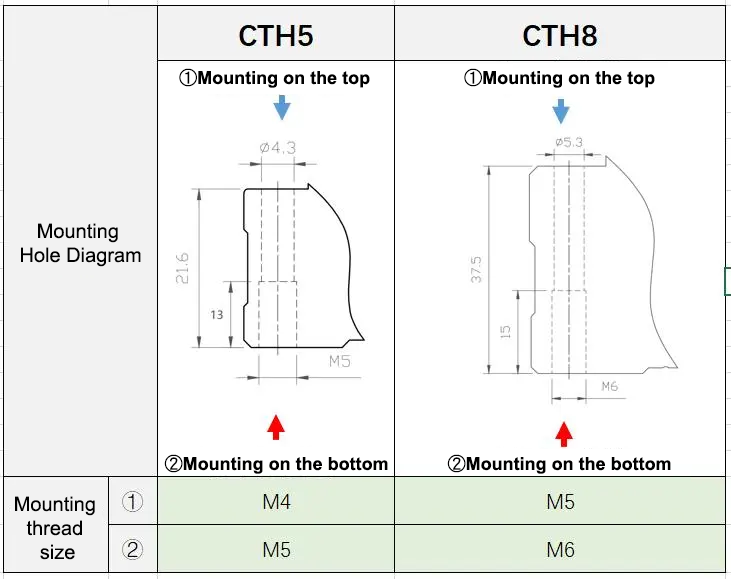

■Motor Mounting Port

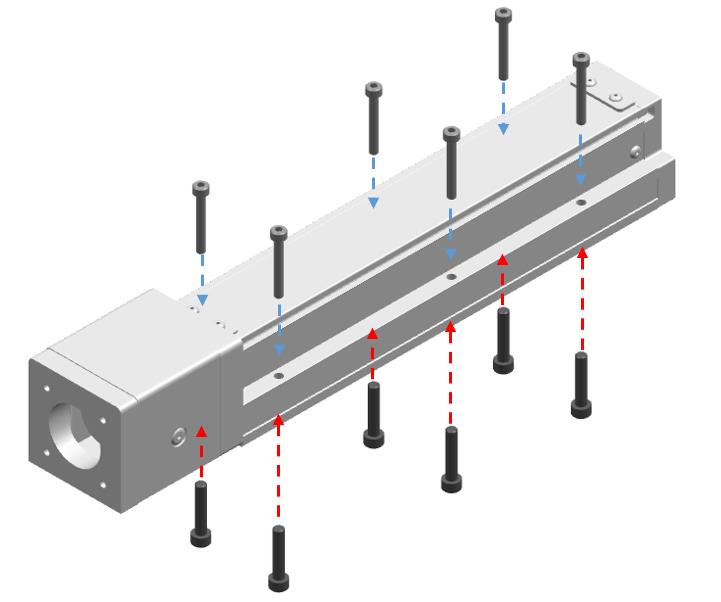

■Mounting Method

| Horizontal Installation | |

| MY | 318 |

| MP | 318 |

| MR | 626 |

■List of Recommended Servo Motors

| Brand | Motor Code | With/Without Brake | Motor Power | Power Voltage | Servo Motor Model | Servo Drive Model |

| Mitsubishi | M20 | Without Brake (Horizontal Use) | 200W | 220V | HG-KR23 | MR-J4-20A |

| With Brake (Vertical Use) | HG-KR23B | |||||

| M40 | Without Brake (Horizontal Use) | 400W | 220V | HG-KR43 | MR-J4-40A | |

| With Brake (Vertical Use) | HG-KR43B | |||||

| Panasonic | P20 | Without Brake (Horizontal Use) | 200W | 220V | MSMF022L1U | MADLN15SG |

| With Brake (Vertical Use) | MSMF022L1V | |||||

| P40 | Without Brake (Horizontal Use) | 400W | 220V | MSMF042L1U | MADLN25SG | |

| With Brake (Vertical Use) | MSMF042L1V | |||||

| Yaskawa | Y20 | Without Brake (Horizontal Use) | 200W | 220V | SGM7J02AFC6S | SGD7S-1R6A00A002 |

| With Brake (Vertical Use) | SGM7J02AFC6E | |||||

| Y40 | Without Brake (Horizontal Use) | 400W | 220V | SGM7J04AFC6S | SGD7S-2R8A00A002 | |

| With Brake (Vertical Use) | SGM7J04AFC6E | |||||

| Delta | T20 | Without Brake (Horizontal Use) | 200W | 220V | ECMA-C20602RS | ASD-B20221-B |

| With Brake (Vertical Use) | ECMA-C20602SS | |||||

| T40 | Without Brake (Horizontal Use) | 400W | 220V | ECMA-C20604RS | ASD-B20421-B | |

| With Brake (Vertical Use) | ECMA-C20604SS |

■Motor Mounting Port

■Mounting Method

Example of Use

Precautions

Precautions for use

■Avoid using single-axis drive products in the following environments

①Dusty environment (especially metal powder)

②Environment with splashing water and oil

③Near fire sources

④Environment with excessive organic solutions and salt

⑤Environment with direct sunlight and heat radiation

⑥Environment subject to strong vibration and shock

⑦Environment with corrosive gas, combustible gas

■Single-axis robot operating environment

Operating environment: normal temperature (no freezing, non-condensation)

■Avoid using single-axis drive products in the following environments

①Dusty environment (especially metal powder)

②Environment with splashing water and oil

③Near fire sources

④Environment with excessive organic solutions and salt

⑤Environment with direct sunlight and heat radiation

⑥Environment subject to strong vibration and shock

⑦Environment with corrosive gas, combustible gas

■Single-axis robot operating environment

Operating environment: normal temperature (no freezing, non-condensation)

Dimensional Drawing

| Components | Body | Embedded Guide | Screw | Nut | Slide Block | Cover |

Material Material | Aluminum Alloy | Bearing Steel | Carbon Steel | Alloy Steel | Aluminum Alloy | Stainless Steel |

Surface Treatment Surface Treatment | Anodized | - | - | - | Anodized | - |

■Motor Connection Diagram

Dimension (mm), Mass (kg)

| Effective Stroke | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 | 1100 |

| L | 328 | 378 | 428 | 478 | 528 | 578 | 628 | 678 | 728 | 778 | 828 | 878 | 928 | 978 | 1028 | 1078 | 1128 | 1178 | 1228 | 1278 | 1328 | 1378 |

| A | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 |

| M | 1 | 1 | 2 | 2 | 3 | 3 | 4 | 4 | 5 | 5 | 6 | 6 | 7 | 7 | 8 | 8 | 9 | 9 | 10 | 10 | 11 | 11 |

| N | 6 | 6 | 8 | 8 | 10 | 10 | 12 | 12 | 14 | 14 | 16 | 16 | 18 | 18 | 20 | 20 | 22 | 22 | 24 | 24 | 26 | 26 |

| P | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 | 1100 |

| KG | 3.91 | 4.29 | 4.70 | 5.00 | 5.35 | 5.68 | 6.00 | 6.35 | 6.64 | 6.97 | 7.41 | 7.71 | 8.12 | 8.41 | 8.65 | 8.96 | 9.37 | 9.62 | 10.01 | 10.28 | 10.70 | 11.12 |

Dimension (mm), Mass (kg)

| Effective Stroke | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 | 1100 |

| L | 314.5 | 364.5 | 414.5 | 464.5 | 514.5 | 564.5 | 614.5 | 664.5 | 714.5 | 764.5 | 814.5 | 864.5 | 914.5 | 964.5 | 1014.5 | 1064.5 | 1114.5 | 1164.5 | 1214.5 | 1264.5 | 1314.5 | 1364.5 |

| A | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 |

| M | 0 | 0 | 1 | 1 | 2 | 2 | 3 | 3 | 4 | 4 | 5 | 5 | 6 | 6 | 7 | 7 | 8 | 8 | 9 | 9 | 10 | 10 |

| N | 4 | 4 | 6 | 6 | 8 | 8 | 10 | 10 | 12 | 12 | 14 | 14 | 16 | 16 | 18 | 18 | 20 | 20 | 22 | 22 | 24 | 24 |

| P | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 | 1100 |

| KG | 3.95 | 4.33 | 4.74 | 5.09 | 5.39 | 5.72 | 6.04 | 6.39 | 6.68 | 7.01 | 7.45 | 7.75 | 8.16 | 8.45 | 8.69 | 9.00 | 9.41 | 9.66 | 10.08 | 10.32 | 10.74 | 11.16 |

Dimension (mm), Mass (kg)

| Effective Stroke | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 | 1100 |

| L | 314.5 | 364.5 | 414.5 | 464.5 | 514.5 | 564.5 | 614.5 | 664.5 | 714.5 | 764.5 | 814.5 | 864.5 | 914.5 | 964.5 | 1014.5 | 1064.5 | 1114.5 | 1164.5 | 1214.5 | 1264.5 | 1314.5 | 1364.5 |

| A | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 |

| M | 1 | 1 | 2 | 2 | 3 | 3 | 4 | 4 | 5 | 5 | 6 | 6 | 7 | 7 | 8 | 8 | 9 | 9 | 10 | 10 | 11 | 11 |

| N | 6 | 6 | 8 | 8 | 10 | 10 | 12 | 12 | 14 | 14 | 16 | 16 | 18 | 18 | 20 | 20 | 22 | 22 | 24 | 24 | 26 | 26 |

| P | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 | 1100 |

| KG | 3.95 | 4.33 | 4.74 | 5.09 | 5.39 | 5.72 | 6.04 | 6.39 | 6.68 | 7.01 | 7.45 | 7.75 | 8.16 | 8.45 | 8.69 | 9.00 | 9.41 | 9.66 | 10.08 | 10.32 | 10.74 | 11.16 |

Dimension (mm), Mass (kg)

| Effective Stroke | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 | 1100 |

| L | 314.5 | 364.5 | 414.5 | 464.5 | 514.5 | 564.5 | 614.5 | 664.5 | 714.5 | 764.5 | 814.5 | 864.5 | 914.5 | 964.5 | 1014.5 | 1064.5 | 1114.5 | 1164.5 | 1214.5 | 1264.5 | 1314.5 | 1364.5 |

| A | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 | 50 | 100 |

| M | 1 | 1 | 2 | 2 | 3 | 3 | 4 | 4 | 5 | 5 | 6 | 6 | 7 | 7 | 8 | 8 | 9 | 9 | 10 | 10 | 11 | 11 |

| N | 6 | 6 | 8 | 8 | 10 | 10 | 12 | 12 | 14 | 14 | 16 | 16 | 18 | 18 | 20 | 20 | 22 | 22 | 24 | 24 | 26 | 26 |

| P | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 | 1100 |

| KG | 3.95 | 4.33 | 4.74 | 5.09 | 5.39 | 5.72 | 6.04 | 6.39 | 6.68 | 7.01 | 7.45 | 7.75 | 8.16 | 8.45 | 8.69 | 9.00 | 9.41 | 9.66 | 10.08 | 10.32 | 10.74 | 11.16 |

Specification Table

| Part Number |  Lead (mm) Lead (mm) |  Stroke Stroke(50millimeters increments) |  Motor Position |  Motor Brand |  Motor Power |  Sensor Position | Repetitive Positioning Accuracy (mm) | Max. Payload (kg) | Max. Speed (mm/sec) | Rated Thrust (N) | ||

Type Type | Horizontal Use | Vertical Use | 200W | 400W | ||||||||

| E-MCT8 | 5 | 50~1100 | BC (Motor Direct Connection) BM (Motor On Lower Side) BL (Motor On Left Side) BR (Motor On Right Side) | M (Mitsubishi) P (Panasonic) Y (Yaskawa) T (Delta Electronics) Z (Prepared by Customer) | 20 (200W) 40 (400W) | C (External Motor Side) D (External Motor Opposite Side) | ±0.01 | 50 | 15 | 250 | 683 | 1388 |

| 10 | 30 | 8 | 500 | 341 | 694 | |||||||

| 20 | 18 | 3 | 1000 | 174 | 347 | |||||||

A motor is not included to this product and it must be purchased separately.

A motor is not included to this product and it must be purchased separately. When the stroke exceeds 600mm, ball screw resonance will occur. In this case, reduce the movement speed.

When the stroke exceeds 600mm, ball screw resonance will occur. In this case, reduce the movement speed. Select a motor with brake for vertical use.

Select a motor with brake for vertical use. When Z is selected as the motor brand (prepared by customer), please provide the motor model and power when placing an order. (If necessary, provide the motor mounting dimensions)

When Z is selected as the motor brand (prepared by customer), please provide the motor model and power when placing an order. (If necessary, provide the motor mounting dimensions) As the drawings are schematic diagrams, please confirm the detailed dimensions according to CAD data.

As the drawings are schematic diagrams, please confirm the detailed dimensions according to CAD data.| Part Number | Lead (mm) | Motor Power (W) | Max. Movement Speed (mm/sec) | |||||||||||||||||||||

| 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 | 1100 | |||

| E-MCT8 | 5 | 200 | 250 | 225 | 200 | 175 | 150 | 125 | 100 | 75 | ||||||||||||||

| 10 | 500 | 450 | 400 | 350 | 300 | 250 | 200 | 150 | ||||||||||||||||

| 20 | 1000 | 900 | 800 | 700 | 600 | 500 | 400 | 300 | ||||||||||||||||

| 5 | 400 | 250 | 225 | 200 | 175 | 150 | 125 | 100 | 75 | |||||||||||||||

| 10 | 500 | 450 | 400 | 350 | 300 | 250 | 200 | 150 | ||||||||||||||||

| 20 | 1000 | 900 | 800 | 700 | 600 | 500 | 400 | 300 | ||||||||||||||||

Values in the table are reference values calculated according to the critical speed and DN value of the ball screw.

Values in the table are reference values calculated according to the critical speed and DN value of the ball screw. Values in the table are maximum safety speeds available for each stroke. As ball screws may resonate at longer strokes, such conditions as abnormal sound and vibration may occur when operating at the maximum speed. Therefore, the moving speed should be reduced appropriately.

Values in the table are maximum safety speeds available for each stroke. As ball screws may resonate at longer strokes, such conditions as abnormal sound and vibration may occur when operating at the maximum speed. Therefore, the moving speed should be reduced appropriately.Part Number

- Incomplete part number.

Please use left hand selections to complete a part number.

Loading...

| Part Number |

|---|

| E-MCT8-L5-[50-1100/50]-[BC,BL,BM,BR]-M[20,40]-[C,D] |

| E-MCT8-L5-[50-1100/50]-[BC,BL,BM,BR]-P[20,40]-[C,D] |

| E-MCT8-L5-[50-1100/50]-[BC,BL,BM,BR]-T[20,40]-[C,D] |

| E-MCT8-L5-[50-1100/50]-[BC,BL,BM,BR]-Y[20,40]-[C,D] |

| E-MCT8-L5-[50-1100/50]-[BC,BL,BM,BR]-Z-[C,D] |

| E-MCT8-L10-[50-1100/50]-[BC,BL,BM,BR]-M[20,40]-[C,D] |

| E-MCT8-L10-[50-1100/50]-[BC,BL,BM,BR]-P[20,40]-[C,D] |

| E-MCT8-L10-[50-1100/50]-[BC,BL,BM,BR]-T[20,40]-[C,D] |

| E-MCT8-L10-[50-1100/50]-[BC,BL,BM,BR]-Y[20,40]-[C,D] |

| E-MCT8-L10-[50-1100/50]-[BC,BL,BM,BR]-Z-[C,D] |

| E-MCT8-L20-[50-1100/50]-[BC,BL,BM,BR]-M[20,40]-[C,D] |

| E-MCT8-L20-[50-1100/50]-[BC,BL,BM,BR]-P[20,40]-[C,D] |

| E-MCT8-L20-[50-1100/50]-[BC,BL,BM,BR]-T[20,40]-[C,D] |

| E-MCT8-L20-[50-1100/50]-[BC,BL,BM,BR]-Y[20,40]-[C,D] |

| E-MCT8-L20-[50-1100/50]-[BC,BL,BM,BR]-Z-[C,D] |

| Part Number | Price | Minimum Order Qty. | Volume Discount | Days to Ship | Lead | Effective Stroke (mm) | Motor Position | Motor Brand & Power | Sensor Position |

|---|---|---|---|---|---|---|---|---|---|

- | 1 Piece(s) | 13 Day(s) | 5 | 50 ~ 1100 | BC Motor Direct Connection / BL Motor On Left Side / BM Motor On Lower Side / BR Motor On Right Side | M20 Mitsubishi 200W / M40 Mitsubishi 400W | C Motor Side / D Motor Opposite Side | ||

- | 1 Piece(s) | 13 Day(s) | 5 | 50 ~ 1100 | BC Motor Direct Connection / BL Motor On Left Side / BM Motor On Lower Side / BR Motor On Right Side | P20 Panasonic 200W / P40 Panasonic 400W | C Motor Side / D Motor Opposite Side | ||

- | 1 Piece(s) | 13 Day(s) | 5 | 50 ~ 1100 | BC Motor Direct Connection / BL Motor On Left Side / BM Motor On Lower Side / BR Motor On Right Side | T20 Delta 200W / T40 Delta 400W | C Motor Side / D Motor Opposite Side | ||

- | 1 Piece(s) | 13 Day(s) | 5 | 50 ~ 1100 | BC Motor Direct Connection / BL Motor On Left Side / BM Motor On Lower Side / BR Motor On Right Side | Y20 Yaskawa 200W / Y40 Yaskawa 400W | C Motor Side / D Motor Opposite Side | ||

- | 1 Piece(s) | 13 Day(s) | 5 | 50 ~ 1100 | BC Motor Direct Connection / BL Motor On Left Side / BM Motor On Lower Side / BR Motor On Right Side | Z Prepared by Customer | C Motor Side / D Motor Opposite Side | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 50 ~ 1100 | BC Motor Direct Connection / BL Motor On Left Side / BM Motor On Lower Side / BR Motor On Right Side | M20 Mitsubishi 200W / M40 Mitsubishi 400W | C Motor Side / D Motor Opposite Side | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 50 ~ 1100 | BC Motor Direct Connection / BL Motor On Left Side / BM Motor On Lower Side / BR Motor On Right Side | P20 Panasonic 200W / P40 Panasonic 400W | C Motor Side / D Motor Opposite Side | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 50 ~ 1100 | BC Motor Direct Connection / BL Motor On Left Side / BM Motor On Lower Side / BR Motor On Right Side | T20 Delta 200W / T40 Delta 400W | C Motor Side / D Motor Opposite Side | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 50 ~ 1100 | BC Motor Direct Connection / BL Motor On Left Side / BM Motor On Lower Side / BR Motor On Right Side | Y20 Yaskawa 200W / Y40 Yaskawa 400W | C Motor Side / D Motor Opposite Side | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 50 ~ 1100 | BC Motor Direct Connection / BL Motor On Left Side / BM Motor On Lower Side / BR Motor On Right Side | Z Prepared by Customer | C Motor Side / D Motor Opposite Side | ||

- | 1 Piece(s) | 13 Day(s) | 20 | 50 ~ 1100 | BC Motor Direct Connection / BL Motor On Left Side / BM Motor On Lower Side / BR Motor On Right Side | M20 Mitsubishi 200W / M40 Mitsubishi 400W | C Motor Side / D Motor Opposite Side | ||

- | 1 Piece(s) | 13 Day(s) | 20 | 50 ~ 1100 | BC Motor Direct Connection / BL Motor On Left Side / BM Motor On Lower Side / BR Motor On Right Side | P20 Panasonic 200W / P40 Panasonic 400W | C Motor Side / D Motor Opposite Side | ||

- | 1 Piece(s) | 13 Day(s) | 20 | 50 ~ 1100 | BC Motor Direct Connection / BL Motor On Left Side / BM Motor On Lower Side / BR Motor On Right Side | T20 Delta 200W / T40 Delta 400W | C Motor Side / D Motor Opposite Side | ||

- | 1 Piece(s) | 13 Day(s) | 20 | 50 ~ 1100 | BC Motor Direct Connection / BL Motor On Left Side / BM Motor On Lower Side / BR Motor On Right Side | Y20 Yaskawa 200W / Y40 Yaskawa 400W | C Motor Side / D Motor Opposite Side | ||

- | 1 Piece(s) | 13 Day(s) | 20 | 50 ~ 1100 | BC Motor Direct Connection / BL Motor On Left Side / BM Motor On Lower Side / BR Motor On Right Side | Z Prepared by Customer | C Motor Side / D Motor Opposite Side |

Loading...

Basic Information

| Type | Slider | Drive Method | Rolled Ball Screw | Main Body, Peripheral Components | Main Body |

|---|---|---|---|---|---|

| Positioning Repeatability(µm) | ±10 | Environmental Spec. | Clean Spec. | Cable | Not Provided |

| Number of Tables | 1 pc. |

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy