(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Due to an increase in demand, the lead time of some of the electrical items from our eCatalogue has increased abnormally and may cause delays in delivery or order suspension. We apologize for the inconvenience and appreciate your kind understanding. Once the supply will get normalized, we will update the same.

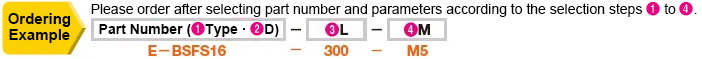

Specification/Dimensions

-

type

- E-BSFS

-

Shaft Outer Dia. D(Ø)

-

Shaft Overall Length L(mm)

-

Spline shaft Left end Tapping [M](mm)

-

CAD

- 2D

- 3D

Days to Ship

-

- All

- 11 Day(s) or Less

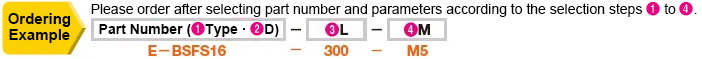

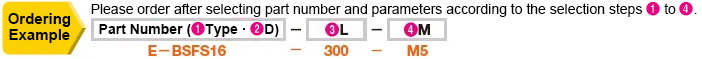

Specify Alterations

Ball Splines Key Provided Straight Nut, One End Tapped

You can add up to 6 items per a category to the compare list.

Brand :

MiSUMi Economy

Part Number :

Copy Part Number URL to Clipboard

The part number URL has been copied into your clipboard.-

- Order Qty :

-

-

- Price :

- ---

-

- Total Price :

- ---

-

- Days to ship :

- ---

Select part number to Order Now/ Add to Cart

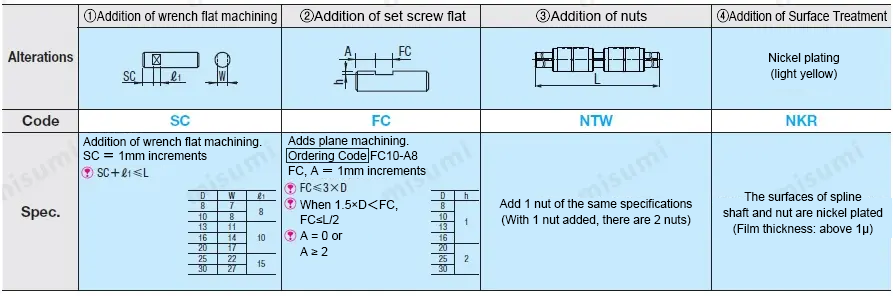

When ③ is configured, there is no guarantee that the keyway positions of the 2 nuts are concentric.

When ③ is configured, there is no guarantee that the keyway positions of the 2 nuts are concentric.

When ④ is configured, the surface will be light yellow, and there may be a color difference.

When ④ is configured, the surface will be light yellow, and there may be a color difference.

Due to the surface treatment process, the following parts are more susceptible to rust.

-Cut section

-Groove part

-Cut section

-Tapped part

The relative positions of the grooves of spline shaft, the keyways and oil holes of nuts, and all the alterations (wrench flat, set screw flat, etc.) in the 3D model are for reference only and may differ from their actual positions.

The relative positions of the grooves of spline shaft, the keyways and oil holes of nuts, and all the alterations (wrench flat, set screw flat, etc.) in the 3D model are for reference only and may differ from their actual positions.

Product Overview

1. Ball spline rolls along the spherical groove using the steel ball inside the spline nut, allowing even a single-axis mechanism to perform linear motion while keeping the nut undeviated in the rotation direction.

2. Compared to the combination of guide shaft and linear bushing, ball spline enables linear motion with high sensitivity and high precision, and can withstand higher loads.

3. Ball spline can safely transmit torque even under cantilever load and deliver high durability.

2. Compared to the combination of guide shaft and linear bushing, ball spline enables linear motion with high sensitivity and high precision, and can withstand higher loads.

3. Ball spline can safely transmit torque even under cantilever load and deliver high durability.

Product Features

1. Shipping within 5 days after placing an order.

2. Drawing-based machining is no longer required, saving the time for design.

3. Spline shaft length can be specified in 1mm increments.

4. Various alterations are available to meet different usage scenarios.

5. This product has a lower price compared to the MISUMI standard products (produced in Japan) and better performance compared to generic products on the market.

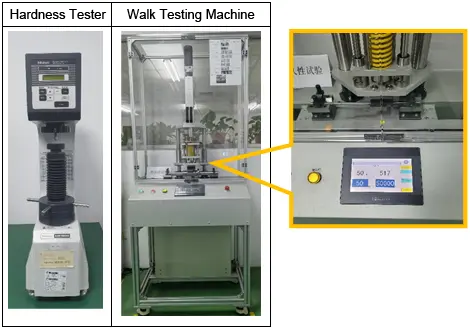

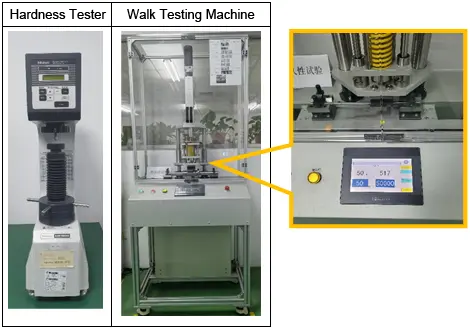

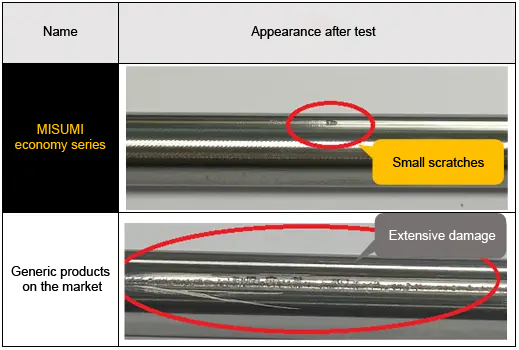

■We have professional testing equipment for guaranteed quality

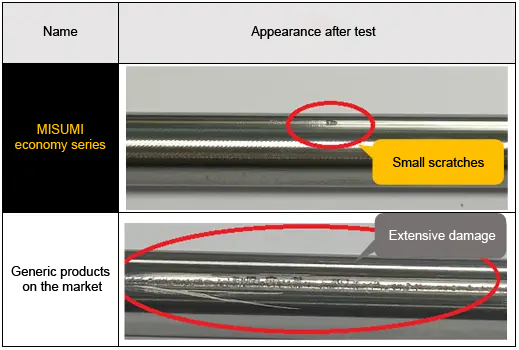

■For this product and Generic Products on the Market, we have conducted a service life comparison using a traveling tester.

→Test conditions:

Load: 50kgf

Speed: 40cm/s

Travel distance: 100km

Spline shaft diameter: 8mm

→Test result:

* Generic products on the market are similar products randomly purchased by our company from online or offline markets.

* The test data are obtained through testing by our company, which are for reference only.

2. Drawing-based machining is no longer required, saving the time for design.

3. Spline shaft length can be specified in 1mm increments.

4. Various alterations are available to meet different usage scenarios.

5. This product has a lower price compared to the MISUMI standard products (produced in Japan) and better performance compared to generic products on the market.

■We have professional testing equipment for guaranteed quality

■For this product and Generic Products on the Market, we have conducted a service life comparison using a traveling tester.

→Test conditions:

Load: 50kgf

Speed: 40cm/s

Travel distance: 100km

Spline shaft diameter: 8mm

→Test result:

* Generic products on the market are similar products randomly purchased by our company from online or offline markets.

* The test data are obtained through testing by our company, which are for reference only.

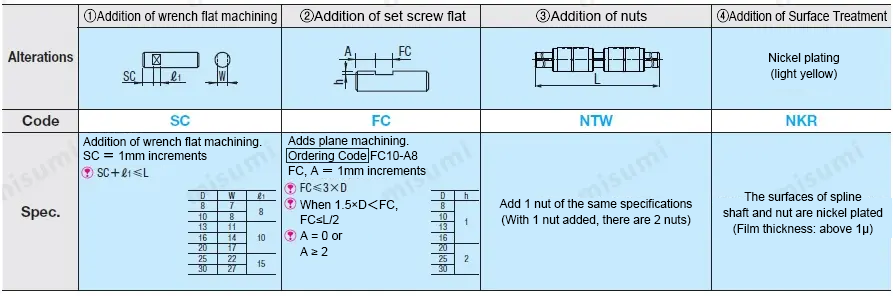

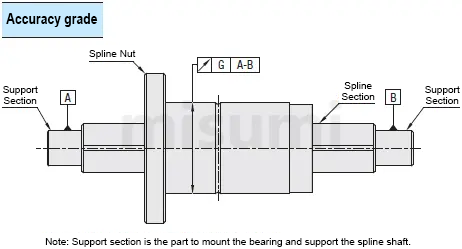

Product Drawings (Unit: mm)

| Accuracy grade | Spline shaft | Nut | ||||||

| Type |  Material Material |  Hardness Hardness |  Surface Treatment Surface Treatment | Type |  Material Material |  Hardness Hardness |  Surface Treatment Surface Treatment | |

| Grade N | Solid | Equivalent to SUJ2 | 58HRC~ | - | Straight | Equivalent to SCR420 | 58HRC~ | - |

Specification Table

Type Type |  Dh8 |  L L1mm increments |  M (Coarse) M (Coarse)Selection | D1 | L1 | L2 | L3 | bH8 | h | r | t | u | Basic Rated Torque | Basic Load Rating | Static Allowable Moment | |||||||||||

| Dynamic Ct (N·m) | Static C0t (N·m) | Dynamic C (kN) | Static C0 (kN) | M01 (N·m) | M02 (N·m) | |||||||||||||||||||||

| Tolerance | ||||||||||||||||||||||||||

| E-BSFS | 8 | 60~300 | 3 | 4 | 16 | 0 -0.027 | 27 | 15.7 | 10.5 | 2.5 | 2.5 | 1.25 | 1.2 | 1.5 | 3.3 | 6 | 0.8 | 1.4 | 3.5 | 25.2 | ||||||

| 10 | 60~400 | 3 | 4 | 5 | 21 | 0 -0.033 | 33 | 20 | 13 | 3 | 3 | 1.5 | 1.5 | 13.3 | 23.8 | 2.6 | 3.9 | 9.5 | 85.3 | |||||||

| 13 | 60~400 | 4 | 5 | 6 | 24 | 36 | 23 | 15 | 19.6 | 36.4 | 3.2 | 5.4 | 15 | 124.6 | ||||||||||||

| 16 | 70~600 | 4 | 5 | 6 | 8 | 31 | 0 -0.039 | 50 | 34 | 17.5 | 3.5 | 3.5 | 1.75 | 2 | 2 | 35.7 | 65.1 | 4.3 | 7.7 | 37.1 | 260 | |||||

| 20 | 80~700 | 5 | 6 | 8 | 10 | 35 | 56 | 39.7 | 29 | 4 | 4 | 2 | 2.5 | 59.5 | 107.8 | 5.9 | 10.7 | 55.3 | 380 | |||||||

| 25 | 90~900 | 5 | 6 | 8 | 10 | 12 | 42 | 71 | 50.3 | 36 | 3 | 135.1 | 243.6 | 10 | 15 | 103.5 | 685.9 | |||||||||

| 30 | 100~900 | 6 | 8 | 10 | 12 | 16 | 47 | 80 | 60 | 42 | 190.4 | 343 | 11 | 19.6 | 148.4 | 932.7 | ||||||||||

When ③ is configured, there is no guarantee that the keyway positions of the 2 nuts are concentric.

When ③ is configured, there is no guarantee that the keyway positions of the 2 nuts are concentric. When ④ is configured, the surface will be light yellow, and there may be a color difference.

When ④ is configured, the surface will be light yellow, and there may be a color difference.Due to the surface treatment process, the following parts are more susceptible to rust.

-Cut section

-Groove part

-Cut section

-Tapped part

The relative positions of the grooves of spline shaft, the keyways and oil holes of nuts, and all the alterations (wrench flat, set screw flat, etc.) in the 3D model are for reference only and may differ from their actual positions.

The relative positions of the grooves of spline shaft, the keyways and oil holes of nuts, and all the alterations (wrench flat, set screw flat, etc.) in the 3D model are for reference only and may differ from their actual positions.

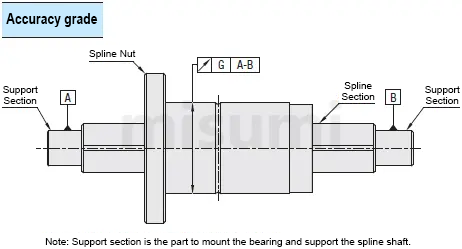

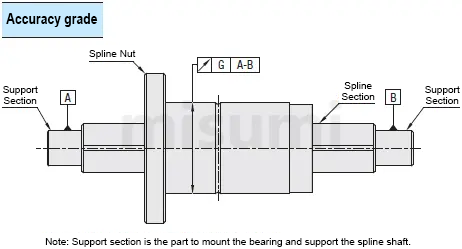

Unit: μm

| Max. Runout of Spline Axis Line | |||||||

| Shaft Dia. D | ~200 | 201~315 | 316~400 | 401~500 | 501~630 | 631~800 | 801~900 |

| 8 | 72 | 133 | 185 | 236 | - | - | - |

| 10 | 59 | 83 | 103 | 123 | 151 | 190 | - |

| 13 | 56 | 71 | 83 | 95 | 112 | 137 | 170 |

| 16 | |||||||

| 20 | |||||||

| 25 | 53 | 58 | 70 | 78 | 88 | 103 | 124 |

| 30 | |||||||

Related Products

Precautions

■Precautions for Selection and Use

1. The relative positions of the grooves of spline shaft, the keyways and oil holes of straight nuts, and all the alterations (wrench flat, set screw flat, etc.) in the 3D model are for reference only and may differ from their actual positions.

2. When re-inserting a nut into the spline shaft, be sure to insert it horizontally, otherwise the ball will fall off.

3. As resin parts are used inside the nuts, please use them at temperatures below 80℃.

4. Although the nuts are greased on the inside before leaving the factory, please re-grease them every 2~3 months or every 50km of traveling distance after receipt of the goods, otherwise their use will be impaired.

5. No guarantee is given for the noise level of this product.

6. No guarantee is given that the spline shaft or nuts of this product will fall freely.

7. This product is a machined type, so there will be knife patterns and color difference in its appearance. It is normal for the product to have some scratches or color changes. Please feel free to use.

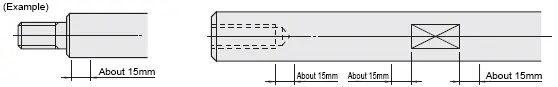

8. The spline shaft is quenched, and annealed during machining.

Due to the annealing treatment, the hardness of the machined part + area about 15 mm before and after the part may be reduced (see the following example). And the annealed section is out of the guaranteed range of outer diameter dimensional tolerance.

Subtract the size of the annealed section when calculating the stroke.

1. The relative positions of the grooves of spline shaft, the keyways and oil holes of straight nuts, and all the alterations (wrench flat, set screw flat, etc.) in the 3D model are for reference only and may differ from their actual positions.

2. When re-inserting a nut into the spline shaft, be sure to insert it horizontally, otherwise the ball will fall off.

3. As resin parts are used inside the nuts, please use them at temperatures below 80℃.

4. Although the nuts are greased on the inside before leaving the factory, please re-grease them every 2~3 months or every 50km of traveling distance after receipt of the goods, otherwise their use will be impaired.

5. No guarantee is given for the noise level of this product.

6. No guarantee is given that the spline shaft or nuts of this product will fall freely.

7. This product is a machined type, so there will be knife patterns and color difference in its appearance. It is normal for the product to have some scratches or color changes. Please feel free to use.

8. The spline shaft is quenched, and annealed during machining.

Due to the annealing treatment, the hardness of the machined part + area about 15 mm before and after the part may be reduced (see the following example). And the annealed section is out of the guaranteed range of outer diameter dimensional tolerance.

Subtract the size of the annealed section when calculating the stroke.

The parts that may be reduced in hardness due to annealing are:

·Threaded parts

·Stepped parts

·Tapped parts

·Alterations of wrench flats, set screw flat, retaining ring grooves, and tapped holes

·Threaded parts

·Stepped parts

·Tapped parts

·Alterations of wrench flats, set screw flat, retaining ring grooves, and tapped holes

Example of Use

Part Number

- Incomplete part number.

Please use left hand selections to complete a part number.

Loading...

| Part Number |

|---|

| E-BSFS8-[60-300/1]-M[3,4] |

| E-BSFS10-[60-400/1]-M[3,4,5] |

| E-BSFS13-[60-400/1]-M[4,5,6] |

| E-BSFS16-[70-600/1]-M[4,5,6,8] |

| E-BSFS20-[80-700/1]-M[5,6,8,10] |

| E-BSFS25-[90-900/1]-M[5,6,8,10,12] |

| E-BSFS30-[100-900/1]-M[6,8,10,12,16] |

| Part Number | Price | Minimum Order Qty. | Volume Discount | Days to Ship | Shaft Outer Dia. D (Ø) | Shaft Overall Length L (mm) | Spline shaft Left end Tapping [M] (mm) |

|---|---|---|---|---|---|---|---|

- | 1 Piece(s) | 11 Day(s) | 8 | 60 ~ 300 | 3 ~ 4 | ||

- | 1 Piece(s) | 11 Day(s) | 10 | 60 ~ 400 | 3 ~ 5 | ||

- | 1 Piece(s) | 11 Day(s) | 13 | 60 ~ 400 | 4 ~ 6 | ||

- | 1 Piece(s) | 11 Day(s) | 16 | 70 ~ 600 | 4 ~ 8 | ||

- | 1 Piece(s) | 11 Day(s) | 20 | 80 ~ 700 | 5 ~ 10 | ||

- | 1 Piece(s) | 11 Day(s) | 25 | 90 ~ 900 | 5 ~ 12 | ||

- | 1 Piece(s) | 11 Day(s) | 30 | 100 ~ 900 | 6 ~ 16 |

Loading...

Dimensional Drawing

| Accuracy grade | Spline shaft | Nut | ||||||

| Type |  Material Material |  Hardness Hardness |  Surface Treatment Surface Treatment | Type |  Material Material |  Hardness Hardness |  Surface Treatment Surface Treatment | |

| Grade N | Solid | Equivalent to SUJ2 | 58HRC~ | - | Straight | Equivalent to SCR420 | 58HRC~ | - |

Specification Table

Type Type |  Dh8 |  L L1mm increments |  M (Coarse) M (Coarse)Selection | D1 | L1 | L2 | L3 | bH8 | h | r | t | u | Basic Rated Torque | Basic Load Rating | Static Allowable Moment | |||||||||||

| Dynamic Ct (N·m) | Static C0t (N·m) | Dynamic C (kN) | Static C0 (kN) | M01 (N·m) | M02 (N·m) | |||||||||||||||||||||

| Tolerance | ||||||||||||||||||||||||||

| E-BSFS | 8 | 60~300 | 3 | 4 | 16 | 0 -0.027 | 27 | 15.7 | 10.5 | 2.5 | 2.5 | 1.25 | 1.2 | 1.5 | 3.3 | 6 | 0.8 | 1.4 | 3.5 | 25.2 | ||||||

| 10 | 60~400 | 3 | 4 | 5 | 21 | 0 -0.033 | 33 | 20 | 13 | 3 | 3 | 1.5 | 1.5 | 13.3 | 23.8 | 2.6 | 3.9 | 9.5 | 85.3 | |||||||

| 13 | 60~400 | 4 | 5 | 6 | 24 | 36 | 23 | 15 | 19.6 | 36.4 | 3.2 | 5.4 | 15 | 124.6 | ||||||||||||

| 16 | 70~600 | 4 | 5 | 6 | 8 | 31 | 0 -0.039 | 50 | 34 | 17.5 | 3.5 | 3.5 | 1.75 | 2 | 2 | 35.7 | 65.1 | 4.3 | 7.7 | 37.1 | 260 | |||||

| 20 | 80~700 | 5 | 6 | 8 | 10 | 35 | 56 | 39.7 | 29 | 4 | 4 | 2 | 2.5 | 59.5 | 107.8 | 5.9 | 10.7 | 55.3 | 380 | |||||||

| 25 | 90~900 | 5 | 6 | 8 | 10 | 12 | 42 | 71 | 50.3 | 36 | 3 | 135.1 | 243.6 | 10 | 15 | 103.5 | 685.9 | |||||||||

| 30 | 100~900 | 6 | 8 | 10 | 12 | 16 | 47 | 80 | 60 | 42 | 190.4 | 343 | 11 | 19.6 | 148.4 | 932.7 | ||||||||||

Alterations

When ③ is configured, there is no guarantee that the keyway positions of the 2 nuts are concentric.

When ③ is configured, there is no guarantee that the keyway positions of the 2 nuts are concentric. When ④ is configured, the surface will be light yellow, and there may be a color difference.

When ④ is configured, the surface will be light yellow, and there may be a color difference.Due to the surface treatment process, the following parts are more susceptible to rust.

-Cut section

-Groove part

-Cut section

-Tapped part

The relative positions of the grooves of spline shaft, the keyways and oil holes of nuts, and all the alterations (wrench flat, set screw flat, etc.) in the 3D model are for reference only and may differ from their actual positions.

The relative positions of the grooves of spline shaft, the keyways and oil holes of nuts, and all the alterations (wrench flat, set screw flat, etc.) in the 3D model are for reference only and may differ from their actual positions.

Unit: μm

| Max. Runout of Spline Axis Line | |||||||

| Shaft Dia. D | ~200 | 201~315 | 316~400 | 401~500 | 501~630 | 631~800 | 801~900 |

| 8 | 72 | 133 | 185 | 236 | - | - | - |

| 10 | 59 | 83 | 103 | 123 | 151 | 190 | - |

| 13 | 56 | 71 | 83 | 95 | 112 | 137 | 170 |

| 16 | |||||||

| 20 | |||||||

| 25 | 53 | 58 | 70 | 78 | 88 | 103 | 124 |

| 30 | |||||||

Basic Information

| Nut Type | Compact Flange | Type | Solid Shaft | End Shape (Left) | Tapped |

|---|---|---|---|---|---|

| End Shape (Right) | Standard | Shaft material | SUJ2 Equivalent | Nut Material | SCR420 Equivalent |

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Frequently asked question (FAQ)

- Question: Do the 3D model on the official website and the actual product have the same positional relationships between the grooves of the spline shafts, the keyways and oil holes of the straight cylinder nuts, and all alterations (wrench slots, planes, etc.)?

- Answer: They may be different.

- Question: Can it be used in high-temperature or special environments?

- Answer: The ball spline uses resin parts. Please use it in environments below 80° C and avoid using it under high temperature conditions or in special environments.

- Question: Can the nut be removed from the spline shaft?

- Answer: As there is a retainer inside the nut, even if removed, the steel ball is less likely to fall. However, it is recommended not to remove it. If it must be removed, please be careful to prevent the steel ball from falling.

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy