(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

Specification/Dimensions

-

Inscribed Circle Dia. dr(Ø)

-

Overall Length L(mm)

-

Outer Dia. D(Ø)

-

Eccentricity(µm)

-

type

- C-LMKC□DMUU

-

CAD

- 2D

- 3D

Days to Ship

-

- All

- Same day

Specify Alterations

Square, Center Flanged Linear Bushings, Medium

- Volume Discount

Copy Part Number URL to Clipboard

The part number URL has been copied into your clipboard.-

- Order Qty :

-

-

- Total Price :

- ---

-

- Days to ship :

- ---

Select part number to Order Now/ Add to Cart

Economy Square Center Flanged Linear Bushing

- Robust design with square flange for enhanced stability.

- Wide range of sizes to suit various applications.

- High-quality SUJ2 equivalent material ensures long-lasting performance.

- Double ball recirculating type for efficient motion.

- Ideal for packaging machines and robotic equipment.

![]()

MISUMI Standard

![]()

Cheaper Price

![]()

Product Variety

![]()

3D CAD Support

Product Overview of Linear Bushings

The middle flanged linear bearing allows workpieces to be installed near the center of the linear bearing body, ensuring good balance on two sides of the flange, as well as decentralized load space.

Product Features of Linear Bushings

Through the rolling of steel ball, high-efficiency movement with low friction resistance can be realized.

Linear Bushings Feature 1: Effective utilization of space. The combination of the guide shaft and the linear bearing enables effective use of space, suitable for small mechanism designs.

Linear Bushings Feature 2: Good interchangeability. Linear bearings have good interchangeability because they can be used with shafts randomly.

Linear Bushings Feature 3: Overall length is about 1.5 times and allowable moment about 4.3 times that of the single liner type.

Linear Bushings Feature 4: Appropriate specifications can be selected according to the conditions of use.

Linear Bushings Feature 5: More cost effective than the linear guide.

Dimensional Drawing of Linear Bushings

Specifications Overview of Linear Bushings

| Housing | Ball | Retainer | Operating Environment Temperature |  Attachments Attachments | ||

Material Material |  Hardness Hardness |  Surface Treatment Surface Treatment |  Material Material |  Material Material | ||

| Equivalent to SUJ2 | 58HRC~ | Electroless Nickel Plating | Equivalent to SUJ2 | Resin | -20 to 80℃ | Seal packing Material MaterialNitrile Rubber (-20 to 120℃) |

Usage Method of Linear Bushings

| Product Drawings of Linear Bushings | Instructions for use Linear Bushings | ||||||||

| When the linear bearing is under heavy load (unbalanced load), one piece of single liner type is not applicable. It is recommended to use one piece of double liner type or multiple pieces of single liner type. | ||||||||

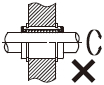

| Linear bearing is not suitable for rotating motion in structure. If you rotate forcibly, it may cause damage to the product. Please pay attention during use. | ||||||||

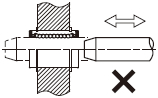

| Linear bearing is not suitable for repeated plugging and unplugging. | ||||||||

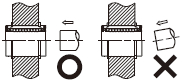

| When inserting the guide shaft into the linear bearing, please align the center and insert it slowly, otherwise the steel ball will fall off or the retainer will be deformed. | ||||||||

Precautions of Linear Bushings

① Before use, please apply grease to the ball row inside the linear bearing, and then replenish it in due course. Grease forms an oil film on the surfaces of steel ball and rolling surface (guide shaft bushing) of linear bearing, which effectively reduces friction and prevents sintering. Grease reduction and aging will greatly affect the life of linear bearing.

② Recommended grease: lithium soap grease.

for details. ③ Recommended grease filling interval: Usually every 6 months.

④When the moving distance is long, it is recommended to move once every three months or when the moving distance exceeds 1000km within the time limit, the 1000km shall prevail.

⑤ When the linear bearing is subjected to large moment load (eccentric load), one piece of single liner type is not applicable, so it is recommended to use one piece of double liner type or multiple pieces of single liner type.

■ Linear Bushings Dust prevention measures:

If dust or foreign matter enters the inside of the linear bearing, it may damage the circulation of steel balls, resulting in unexpected failures. When used in harsh environment, please install dust cover and protection cover, etc.

■ MISUMI linear bearing is recommended to be combined with guide shaft with quenching g6 tolerance.

■ MISUMI linear bearing is recommended to be installed on the holder with H7 tolerance. The linear bearing is in clearance fit with the holder.

Related Documents of Linear Bushings

Usage Method of Linear Bushings.

Usage Method of Linear Bushings.For anti-rust performance and maintenance of metal materials and their surface treatment, please refer to

Anti-rust Performance.

Anti-rust Performance.Application Industries of Linear Bushings

| Electronic & Electrical Appliances | Automotive | Lithium battery | ||

|  |  | ||

| LCD | Smart phone | Semiconductor | ||

|  |  |

Related Products of Linear Bushings

Part Number

- Incomplete part number.

Please use left hand selections to complete a part number.

| Part Number |

|---|

| E-LBKC6DMUU |

| E-LBKC8DMUU |

| E-LBKC10DMUU |

| E-LBKC12DMUU |

| E-LBKC16DMUU |

| E-LBKC20DMUU |

| E-LBKC25DMUU |

| E-LBKC30DMUU |

| Part Number | Price | Minimum Order Qty. | Volume Discount | Days to Ship | RoHS | Inscribed Circle Dia. dr (Ø) | Overall Length L (mm) | Outer Dia. D (Ø) | Eccentricity (µm) | Basic Load Rating: Dynamic Load (Details) (N) | Basic Load Rating: Static Load (N) |

|---|---|---|---|---|---|---|---|---|---|---|---|

₹ 1,290.00 | 1 Piece(s) | Available | Same day | 10 | 6 | 29 | 12 | 0.03 | 226 | 310 | |

₹ 1,300.00 | 1 Piece(s) | Available | Same day | 10 | 8 | 37 | 15 | 0.03 | 310 | 452 | |

₹ 1,420.58 | 1 Piece(s) | Available | Same day | 10 | 10 | 47 | 19 | 0.03 | 508 | 718 | |

₹ 1,482.55 | 1 Piece(s) | Available | Same day | 10 | 12 | 47 | 21 | 0.03 | 634 | 814 | |

₹ 1,736.30 | 1 Piece(s) | Available | Same day | 10 | 16 | 56 | 28 | 0.03 | 1164 | 1448 | |

₹ 1,899.25 | 1 Piece(s) | Available | Same day | 10 | 20 | 65 | 32 | 0.038 | 1554 | 2068 | |

₹ 2,551.62 | 1 Piece(s) | Available | Same day | 10 | 25 | 83 | 40 | 0.038 | 1725 | 3068 | |

₹ 3,028.64 | 1 Piece(s) | Available | Same day | 10 | 30 | 90 | 45 | 0.038 | 2440 | 3974 |

Loading...

| Housing | Ball | Retainer | Operating Environment Temperature |  Attachments Attachments | ||

Material Material |  Hardness Hardness |  Surface Treatment Surface Treatment |  Material Material |  Material Material | ||

| Equivalent to SUJ2 | 58HRC~ | Electroless Nickel Plating | Equivalent to SUJ2 | Resin | -20 to 80℃ | Seal packing Material MaterialNitrile Rubber (-20 to 120℃) |

■Dimension Specification Table

| Part Number | D | L | ℓ | H | T | d | d1 | t | P.C.D. | W | Lateral misalignment | Number of ball rows | * Perpendicularity | Basic Rated Load | Allowable Static Moment (N·m) | Weight (g) | ||||

| dr | Tolerance | Tolerance | Tolerance | C (Dynamic) N | Co (Static) N | Square Flanged | ||||||||||||||

| 6 | 0 -0.01 | 12 | 0 -0.021 | 29 | ±0.3 | 12 | 28 | 5 | 3.5 | 6 | 3.1 | 20 | 22 | 0.03 | 4 | 0.04 | 226 | 310 | 1.42 | 21 |

| 8 | 15 | 37 | 16 | 32 | 24 | 25 | 310 | 452 | 2.12 | 39 | ||||||||||

| 10 | 19 | 0 -0.023 | 47 | 20.5 | 40 | 6 | 4.5 | 7.5 | 4.1 | 29 | 30 | 508 | 718 | 4.37 | 65 | |||||

| 12 | 21 | 42 | 32 | 32 | 634 | 814 | 6.2 | 69 | ||||||||||||

| 16 | 28 | 56 | 25 | 48 | 38 | 37 | 5 | 1164 | 1448 | 13.1 | 132 | |||||||||

| 20 | 0 -0.012 | 32 | 0 -0.028 | 65 | 28.5 | 54 | 8 | 5.5 | 9 | 5.1 | 43 | 42 | 0.038 | 0.04 | 1554 | 2068 | 18.3 | 197 | ||

| 25 | 40 | 83 | 37.5 | 62 | 51 | 50 | 6 | 1725 | 3068 | 25.3 | 442 | |||||||||

| 30 | 45 | 90 | 40 | 74 | 10 | 6.6 | 11 | 6.1 | 60 | 58 | 2440 | 3974 | 42.7 | 482 | ||||||

* mark shows the verticality between Part D and the flange mounting surface.

* mark shows the verticality between Part D and the flange mounting surface. For information on the flanged height adjusting ring, please refer to the

For information on the flanged height adjusting ring, please refer to the  Adjusting Ring.

Adjusting Ring. L, G and H are not engraved on the product.

L, G and H are not engraved on the product.Basic Information

| Type | Flange | Flange Type | Center Flanged | Style | Standard |

|---|---|---|---|---|---|

| Outer Cylinder Material | SUJ2 Equivalent | Outer Cylinder Surface Treatment | Electroless Nickel Plating | Lubrication Type | Not Provided |

| Accuracy | High Grade | Ball Recirculating Type | Double | Motion | Linear |

| Types | Center Flanged | Length | Medium | Ball Material | Equivalent to SUJ2 |

| Retainer Material | Resin | Seal | Provided | Greased Filled | Not Provided |

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Frequently asked question (FAQ)

- Question: How is linear bearing maintained regularly?

- Answer: MISUMI recommends that linear bearing is regularly replenished with grease, and it is recommended to do so once every six months. When the moving distance is long, it is recommended to move once every three months or when the moving distance exceeds 1000km within the time limit, the 1000km shall prevail.

- Question: Comparison of antirust ability of linear bearings?

-

Answer:

Antirust ability from strong to weak: Low Temp. Black Chrome Plating → No-Electro Nickel Plated → No Surface Treatment.

Standard grade bearing steel is easy to rust, so it is necessary to apply anti-rust oil regularly.

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy