(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Please note that the MISUMI India offices and warehouses will remain closed from Oct 31st to Nov 3rd due to the Diwali festival.

Please note that the MISUMI Pune office and warehouse will be closed on November 20th due to the state election. - Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

Specification/Dimensions

-

type

- C-HTBN□□H8M

-

Belt Shape

- Closed End

-

Belt Width (mm)(mm)

-

Core Wire Material

- Glass Fiber

- Glass Fiber

-

Circumference Length(mm)

- 288

- 320

- 336

- 344

- 352

- 368

- 376

- 384

- 400

- 408

- 416

- 424

- 440

- 448

- 456

- 472

- 480

- 488

- 496

- 512

- 520

- 536

- 544

- 552

- 560

- 568

- 576

- 584

- 592

- 600

- 608

- 624

- 632

- 640

- 656

- 664

- 672

- 680

- 688

- 696

- 712

- 720

- 728

- 736

- 744

- 760

- 768

- 776

- 784

- 792

- 800

- 808

- 816

- 824

- 832

- 840

- 848

- 856

- 864

- 872

- 880

- 888

- 896

- 912

- 920

- 928

- 936

- 944

- 952

- 960

- 968

- 976

- 984

- 992

- 1000

- 1008

- 1016

- 1024

- 1032

- 1040

- 1048

- 1056

- 1064

- 1072

- 1080

- 1088

- 1096

- 1104

- 1112

- 1120

- 1128

- 1136

- 1144

- 1152

- 1160

- 1168

- 1176

- 1184

- 1192

- 1200

- 1208

- 1216

- 1224

- 1232

- 1240

- 1248

- 1256

- 1264

- 1272

- 1280

- 1288

- 1296

- 1304

- 1312

- 1320

- 1328

- 1336

- 1344

- 1360

- 1368

- 1384

- 1392

- 1400

- 1408

- 1416

- 1424

- 1432

- 1440

- 1448

- 1456

- 1464

- 1480

- 1512

- 1520

- 1528

- 1536

- 1552

- 1560

- 1576

- 1584

- 1600

- 1608

- 1624

- 1640

- 1648

- 1656

- 1680

- 1696

- 1704

- 1720

- 1728

- 1760

- 1768

- 1776

- 1784

- 1792

- 1800

- 1824

- 1840

- 1848

- 1856

- 1872

- 1880

- 1888

- 1896

- 1904

- 1912

- 1920

- 1936

- 1944

- 1952

- 1960

- 2000

- 2008

- 2016

- 2032

- 2048

- 2056

- 2080

- 2096

- 2104

- 2120

- 2160

- 2176

- 2184

- 2200

- 2208

- 2224

- 2240

- 2248

- 2256

- 2272

- 2304

- 2320

- 2352

- 2392

- 2400

- 2488

- 2504

- 2536

- 2560

- 2600

- 2656

- 2688

- 2736

- 2800

- 2840

- 2848

- 3048

- 3072

- 3120

- 3168

- 3200

- 3264

- 3280

- 3360

- 3400

- 3408

- 3424

- 3600

- 3824

- 4000

- 4224

- 4400

- 4520

- 4656

- 5120

-

Number of Teeth

- 36

- 40

- 42

- 43

- 44

- 46

- 47

- 48

- 50

- 51

- 52

- 53

- 55

- 56

- 57

- 59

- 60

- 61

- 62

- 64

- 65

- 67

- 68

- 69

- 70

- 71

- 72

- 73

- 74

- 75

- 76

- 78

- 79

- 80

- 82

- 83

- 84

- 85

- 86

- 87

- 89

- 90

- 91

- 92

- 93

- 95

- 96

- 97

- 98

- 99

- 100

- 101

- 102

- 103

- 104

- 105

- 106

- 107

- 108

- 109

- 110

- 111

- 112

- 114

- 115

- 116

- 117

- 118

- 119

- 120

- 121

- 122

- 123

- 124

- 125

- 126

- 127

- 128

- 129

- 130

- 131

- 132

- 133

- 134

- 135

- 136

- 137

- 138

- 139

- 140

- 141

- 142

- 143

- 144

- 145

- 146

- 147

- 148

- 149

- 150

- 151

- 152

- 153

- 154

- 155

- 156

- 157

- 158

- 159

- 160

- 161

- 162

- 163

- 164

- 165

- 166

- 167

- 168

- 170

- 171

- 173

- 174

- 175

- 176

- 177

- 178

- 179

- 180

- 181

- 182

- 183

- 185

- 189

- 190

- 191

- 192

- 194

- 195

- 197

- 198

- 200

- 201

- 203

- 205

- 206

- 207

- 210

- 212

- 213

- 215

- 216

- 220

- 221

- 222

- 223

- 224

- 225

- 228

- 230

- 231

- 232

- 234

- 235

- 236

- 237

- 238

- 239

- 240

- 242

- 243

- 244

- 245

- 250

- 251

- 252

- 254

- 256

- 257

- 260

- 262

- 263

- 265

- 270

- 272

- 273

- 275

- 276

- 278

- 280

- 281

- 282

- 284

- 288

- 290

- 294

- 299

- 300

- 311

- 313

- 317

- 320

- 325

- 332

- 336

- 342

- 350

- 355

- 356

- 381

- 384

- 390

- 396

- 400

- 408

- 410

- 420

- 425

- 426

- 428

- 450

- 478

- 500

- 528

- 550

- 565

- 582

- 640

-

CAD

- 2D

- 3D

Days to Ship

-

- All

- Same day

- 14 Day(s) or Less

Specify Alterations

Timing Belts HTD8M (C-HTBN416H8M-400)

- Volume Discount

Copy Part Number URL to Clipboard

The part number URL has been copied into your clipboard.-

- Order Qty :

-

-

- Total Price :

- ---

-

- Days to ship :

- ---

Select part number to Order Now/ Add to Cart

Product Description

Timing Belts HTD8M

It is an arc tooth profile that has higher transmission power than the trapezoidal tooth timing belt.

This belt always uses for high torque transmission in an automation machine

[Features]

• Belt Shape: Closed End

• Belt Tooth Type: H8M (arc tooth profile) • Tooth Pitch: 8 mm.

• Belt Width: 20, 25, 30, 40, 50 and 85 mm.

• Circumference Length Shortest/Longest: 288 mm. and 5120 mm.

• Belt Operating Temperature Range: -10 to 90℃.

• Material:

Tooth rubber: Chloroprene

Core wire: Glass Fiber

Tooth surface protection layer: Nylon canvas

[Applications]

Suitable for use with a timing pulley in a transmission system in an automation machine

Economy HTD 8M Timing Belt

- With a wider range of belt widths and lengths, our HTD 8M belts are designed to handle increased loads and higher torque requirements.

- Constructed with high-quality chloroprene rubber, these belts excel in resisting abrasion, oil, and grease, ensuring extended service life even in demanding environments.

- The unique arc tooth profile delivers higher power transmission compared to traditional trapezoidal profiles, ensuring optimal efficiency and reduced energy loss.

- The arc tooth profile contributes to minimal vibration and noise generation, creating a smoother and quieter operation.

- Engineered to function reliably in temperatures ranging from -10°C to 90°C, these belts offer versatility across various operating conditions.

![]()

MISUMI Standard

![]()

Cheaper Price

![]()

Product Variety

![]()

3D CAD Support

Timing Belt Product Overview

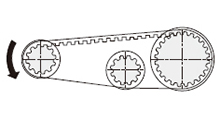

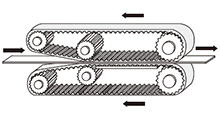

Driving and transmission are realized through the engagement between the teeth of timing pulleys and Timing Belts.

Local production in China delivers MISUMI quality at low price.

Timing Belt Product Features

Feature 1: The arc tooth profile has higher transmission power in comparison with the trapezoidal tooth.

Feature 2: Economical and maintenance free.

Feature 3: The tooth rubber adopts chloroprene to protect core wire from dirt, grease, and wet environments.

Feature 4:·Have certain conductivity.

Feature 5:·Recommended Operating Temperature Range: -10 to 90℃.

Timing Belt Dimensional Drawing

Timing Belt Specifications Overview

Material Material | |

| ① Rear rubber | Chloroprene |

| ② Tooth rubber | |

| ③ Core wire | Glass Fiber |

| ④ Backing cloth | Nylon canvas |

| Types | Tooth pitch | Lr | H | h | PLD |

| H8M | 8 | 5.15 | 6 | 3.38 | 0.686 |

Belt circumference length is core wire length.

Belt circumference length is core wire length. Belt Operating Temperature Range: -10 to 90℃.

Belt Operating Temperature Range: -10 to 90℃. The model engraved on the back of the product is the manufacturer model.

The model engraved on the back of the product is the manufacturer model. MISUMI makes no commitment to this product brand.

MISUMI makes no commitment to this product brand. For the transmission capacity and calculation and design method of economy series Timing Belt, please refer to the national standard (GB) design manual.

For the transmission capacity and calculation and design method of economy series Timing Belt, please refer to the national standard (GB) design manual.Example of Timing Belt Use

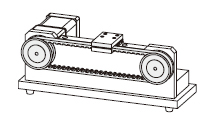

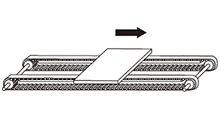

| Timing Belt Usage Method Example Drawing | Instructions for use of timing wheel and Timing Belt |

| ①Driving (The driven wheel is driven by the driving wheel for transmission) |

| ②Transmission (Used for repeated motion with the object not rotating and high requirements on positioning accuracy) |

| Timing Belt Usage Method Example Drawing | Instructions for use of timing wheel and Timing Belt |

| ③Conveyance (Plates are conveyed by two timing toothed belts) |

| ④Traction transmission (Workpieces are clamped and transmitted by the belt) |

Timing Belt Application Industries

| Food | Semiconductor | Smart phone | ||

|  |  | ||

| Automotive | Electronic & Electrical Appliances | Medical | ||

|  |  |

Timing Belt Usage Method

Timing Belt Precautions

Do not use in direct contact with water, solvent, oil, acid, alkali, UV, ozone, etc.③ Please avoid using or keeping at extreme high or low temperatures beyond the operating temperature range, or in humid environments.

④ During installation and maintenance, be sure to cut off the power supply and confirm that the machine is completely stopped before proceeding.

⑤ When there may be impurities, be sure to set the guard.

Timing Belt Related Products

Part Number

- Incomplete part number.

Please use left hand selections to complete a part number.

| Part Number |

|---|

| C-HTBN416H8M-400 |

| Part Number | Price | Minimum Order Qty. | Volume Discount | Days to Ship | RoHS | Belt Shape | Belt Width (mm) (mm) | Core Wire Material | Circumference Length (mm) | Number of Teeth |

|---|---|---|---|---|---|---|---|---|---|---|

₹ 1,128.00 | 2 Piece(s) | Available | 14 Day(s) | 10 | Closed End | 40 | [Glass Fiber] Glass Fiber | 416 | 52 |

Loading...

■Type S8M (Pitch: 8mm)

| M Products Model | Width | Number of Teeth | Circumference Length |

| 288H8M | 200 (20mm) 250 (25mm) 300 (30mm) 400 (40mm) 500 (50mm) 850 (85mm) | 36 | 288 |

| 320H8M | 40 | 320 | |

| 336H8M | 42 | 336 | |

| 344H8M | 43 | 344 | |

| 352H8M | 44 | 352 | |

| 368H8M | 46 | 368 | |

| 376H8M | 47 | 376 | |

| 384H8M | 48 | 384 | |

| 400H8M | 50 | 400 | |

| 408H8M | 51 | 408 | |

| 416H8M | 52 | 416 | |

| 424H8M | 53 | 424 | |

| 440H8M | 55 | 440 | |

| 448H8M | 56 | 448 | |

| 456H8M | 57 | 456 | |

| 472H8M | 59 | 472 | |

| 480H8M | 60 | 480 | |

| 488H8M | 61 | 488 | |

| 496H8M | 62 | 496 | |

| 512H8M | 64 | 512 | |

| 520H8M | 65 | 520 | |

| 536H8M | 67 | 536 | |

| 544H8M | 68 | 544 | |

| 552H8M | 69 | 552 | |

| 560H8M | 70 | 560 | |

| 568H8M | 71 | 568 | |

| 576H8M | 72 | 576 | |

| 584H8M | 73 | 584 | |

| 592H8M | 74 | 592 | |

| 600H8M | 75 | 600 | |

| 608H8M | 76 | 608 | |

| 624H8M | 78 | 624 | |

| 632H8M | 79 | 632 | |

| 640H8M | 80 | 640 | |

| 656H8M | 82 | 656 | |

| 664H8M | 83 | 664 | |

| 672H8M | 84 | 672 | |

| 680H8M | 85 | 680 | |

| 688H8M | 86 | 688 | |

| 696H8M | 87 | 696 | |

| 712H8M | 89 | 712 | |

| 720H8M | 90 | 720 | |

| 728H8M | 91 | 728 | |

| 736H8M | 92 | 736 | |

| 744H8M | 93 | 744 | |

| 760H8M | 95 | 760 | |

| 768H8M | 96 | 768 | |

| 776H8M | 97 | 776 | |

| 784H8M | 98 | 784 | |

| 792H8M | 99 | 792 | |

| 800H8M | 100 | 800 | |

| 808H8M | 101 | 808 | |

| 816H8M | 102 | 816 | |

| 824H8M | 103 | 824 | |

| 832H8M | 104 | 832 | |

| 840H8M | 105 | 840 | |

| 848H8M | 106 | 848 | |

| 856H8M | 107 | 856 | |

| 864H8M | 108 | 864 | |

| 872H8M | 109 | 872 | |

| 880H8M | 110 | 880 | |

| 888H8M | 111 | 888 | |

| 896H8M | 112 | 896 | |

| 912H8M | 114 | 912 | |

| 920H8M | 115 | 920 | |

| 928H8M | 116 | 928 | |

| 936H8M | 117 | 936 | |

| 944H8M | 118 | 944 | |

| 952H8M | 119 | 952 | |

| 960H8M | 120 | 960 | |

| 968H8M | 121 | 968 | |

| 976H8M | 122 | 976 | |

| 984H8M | 123 | 984 | |

| 992H8M | 124 | 992 | |

| 1000H8M | 125 | 1000 | |

| 1008H8M | 126 | 1008 | |

| 1016H8M | 127 | 1016 | |

| 1024H8M | 128 | 1024 | |

| 1032H8M | 129 | 1032 | |

| 1040H8M | 130 | 1040 | |

| 1048H8M | 131 | 1048 | |

| 1056H8M | 132 | 1056 | |

| 1064H8M | 133 | 1064 | |

| 1072H8M | 134 | 1072 | |

| 1080H8M | 135 | 1080 | |

| 1088H8M | 136 | 1088 | |

| 1096H8M | 137 | 1096 | |

| 1104H8M | 138 | 1104 | |

| 1112H8M | 139 | 1112 | |

| 1120H8M | 140 | 1120 | |

| 1128H8M | 141 | 1128 | |

| 1136H8M | 142 | 1136 | |

| 1144H8M | 143 | 1144 | |

| 1152H8M | 144 | 1152 | |

| 1160H8M | 145 | 1160 | |

| 1168H8M | 146 | 1168 | |

| 1176H8M | 147 | 1176 | |

| 1184H8M | 148 | 1184 | |

| 1192H8M | 149 | 1192 | |

| 1200H8M | 150 | 1200 | |

| 1208H8M | 151 | 1208 | |

| 1216H8M | 152 | 1216 | |

| 1224H8M | 153 | 1224 | |

| 1232H8M | 154 | 1232 | |

| 1240H8M | 155 | 1240 | |

| 1248H8M | 156 | 1248 | |

| 1256H8M | 157 | 1256 | |

| 1264H8M | 158 | 1264 | |

| 1272H8M | 159 | 1272 | |

| 1280H8M | 160 | 1280 | |

| 1288H8M | 161 | 1288 | |

| 1296H8M | 162 | 1296 | |

| 1304H8M | 163 | 1304 | |

| 1312H8M | 164 | 1312 | |

| 1320H8M | 165 | 1320 | |

| 1328H8M | 166 | 1328 | |

| 1336H8M | 167 | 1336 | |

| 1344H8M | 168 | 1344 | |

| 1360H8M | 170 | 1360 | |

| 1368H8M | 171 | 1368 | |

| 1384H8M | 173 | 1384 | |

| 1392H8M | 174 | 1392 | |

| 1400H8M | 175 | 1400 | |

| 1408H8M | 176 | 1408 | |

| 1416H8M | 177 | 1416 | |

| 1424H8M | 178 | 1424 | |

| 1432H8M | 179 | 1432 | |

| 1440H8M | 180 | 1440 | |

| 1448H8M | 181 | 1448 | |

| 1456H8M | 182 | 1456 | |

| 1464H8M | 183 | 1464 | |

| 1480H8M | 185 | 1480 | |

| 1512H8M | 189 | 1512 | |

| 1520H8M | 190 | 1520 | |

| 1528H8M | 191 | 1528 | |

| 1536H8M | 192 | 1536 | |

| 1552H8M | 194 | 1552 | |

| 1560H8M | 195 | 1560 | |

| 1576H8M | 197 | 1576 | |

| 1584H8M | 198 | 1584 | |

| 1600H8M | 200 | 1600 | |

| 1608H8M | 201 | 1608 | |

| 1624H8M | 203 | 1624 | |

| 1640H8M | 205 | 1640 | |

| 1648H8M | 206 | 1648 | |

| 1656H8M | 207 | 1656 | |

| 1680H8M | 210 | 1680 | |

| 1696H8M | 212 | 1696 | |

| 1704H8M | 213 | 1704 | |

| 1720H8M | 215 | 1720 | |

| 1728H8M | 216 | 1728 | |

| 1760H8M | 220 | 1760 | |

| 1768H8M | 221 | 1768 | |

| 1776H8M | 222 | 1776 | |

| 1784H8M | 223 | 1784 | |

| 1792H8M | 224 | 1792 | |

| 1800H8M | 225 | 1800 | |

| 1824H8M | 228 | 1824 | |

| 1840H8M | 230 | 1840 | |

| 1848H8M | 231 | 1848 | |

| 1856H8M | 232 | 1856 | |

| 1872H8M | 234 | 1872 | |

| 1880H8M | 235 | 1880 | |

| 1888H8M | 236 | 1888 | |

| 1896H8M | 237 | 1896 | |

| 1904H8M | 238 | 1904 | |

| 1912H8M | 239 | 1912 | |

| 1920H8M | 240 | 1920 | |

| 1936H8M | 242 | 1936 | |

| 1944H8M | 243 | 1944 | |

| 1952H8M | 244 | 1952 | |

| 1960H8M | 245 | 1960 | |

| 2000H8M | 250 | 2000 | |

| 2008H8M | 251 | 2008 | |

| 2016H8M | 252 | 2016 | |

| 2032H8M | 254 | 2032 | |

| 2048H8M | 256 | 2048 | |

| 2056H8M | 257 | 2056 | |

| 2080H8M | 260 | 2080 | |

| 2096H8M | 262 | 2096 | |

| 2104H8M | 263 | 2104 | |

| 2120H8M | 265 | 2120 | |

| 2160H8M | 270 | 2160 | |

| 2176H8M | 272 | 2176 | |

| 2184H8M | 273 | 2184 | |

| 2200H8M | 275 | 2200 | |

| 2208H8M | 276 | 2208 | |

| 2224H8M | 278 | 2224 | |

| 2240H8M | 280 | 2240 | |

| 2248H8M | 281 | 2248 | |

| 2256H8M | 282 | 2256 | |

| 2272H8M | 284 | 2272 | |

| 2304H8M | 288 | 2304 | |

| 2320H8M | 290 | 2320 | |

| 2352H8M | 294 | 2352 | |

| 2392H8M | 299 | 2392 | |

| 2400H8M | 300 | 2400 | |

| 2488H8M | 311 | 2488 | |

| 2504H8M | 313 | 2504 | |

| 2536H8M | 317 | 2536 | |

| 2560H8M | 320 | 2560 | |

| 2600H8M | 325 | 2600 | |

| 2656H8M | 332 | 2656 | |

| 2688H8M | 336 | 2688 | |

| 2736H8M | 342 | 2736 | |

| 2800H8M | 350 | 2800 | |

| 2840H8M | 355 | 2840 | |

| 2848H8M | 356 | 2848 | |

| 3048H8M | 381 | 3048 | |

| 3072H8M | 384 | 3072 | |

| 3120H8M | 390 | 3120 | |

| 3168H8M | 396 | 3168 | |

| 3200H8M | 400 | 3200 | |

| 3264H8M | 408 | 3264 | |

| 3280H8M | 410 | 3280 | |

| 3360H8M | 420 | 3360 | |

| 3400H8M | 425 | 3400 | |

| 3408H8M | 426 | 3408 | |

| 3424H8M | 428 | 3424 | |

| 3600H8M | 450 | 3600 | |

| 3824H8M | 478 | 3824 | |

| 4000H8M | 500 | 4000 | |

| 4224H8M | 528 | 4224 | |

| 4400H8M | 550 | 4400 | |

| 4520H8M | 565 | 4520 | |

| 4656H8M | 582 | 4656 | |

| 5120H8M | 640 | 5120 |

Basic Information

| Belt Type | HTD 8M | Belt Material | Rubber Belt | Belt Tooth Surface | Standard (Single Sided) |

|---|---|---|---|---|---|

| Belt Shape Type | Circular Tooth Profile HTD Belt | Transmission Torque | High Torque Transmission |

Please check the type/dimensions/specifications of the part C-HTBN416H8M-400 in the Timing Belts HTD8M series.

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Frequently asked question (FAQ)

- Question: Why is the order model of the timing belt inconsistent with the actual belt label and engraving?

- Answer: Order model is MISUMI product model, the label on the belt or printed model on the belt surface is the belt manufacturer model, which varies with manufacturer, but there will be no influence on the product itself.

- Question: The timing belt has been broken after use for a very short period of time. Is there a problem with the quality of the belt?

-

Answer:

The timing belt is a standard product, and the same batch of products have very few individual quality problems, please refer to 【Main causes of premature breakage and corresponding countermeasures】to troubleshoot the equipment in use.

- Question: Can alteration be made to the timing belt?

- Answer: Alteration cannot be made to the circumference of the timing belt, and partial alteration can be made to the width.

- Question: What kind of belt is better to use under conditions that require high cleanliness?

- Answer: The use of urethane belts is recommended, which has significantly improved dust drop, compared to the rubber belt.

- Question: What are the two main types of timing belts according to their functions? What is the role?

- Answer: Timing belts are mainly divided into transmission type and driving type. For transmission type, the load can be placed on the timing belt surface for transmission. For driving type, no load is carried, and only the role of transmitting torque is played, which is similar to the role of chain.

- Question: How to judge or measure whether the belt tension meets the installation requirements?

- Answer: It is recommended that the customer purchase the tension meter by himself and make a judgment according to the calculation formula of the initial design.

- Question: Which tooth type of the timing belt has the smallest clearance? What will it affect?

- Answer: The arc tooth type has minimum clearance, which can improve such indicators as positioning accuracy and rigidity.

Product variants

| Part Number |

|---|

| C-HTBN1000H8M-400 |

| C-HTBN1000H8M-500 |

| C-HTBN1000H8M-850 |

| C-HTBN416H8M-500 |

| C-HTBN416H8M-850 |

| C-HTBN4224H8M-200 |

| Part Number | Standard Unit Price | Minimum order quantity | Volume Discount | Days to Ship | RoHS | Belt Shape | Belt Width (mm) (mm) | Core Wire Material | Circumference Length (mm) | Number of Teeth |

|---|---|---|---|---|---|---|---|---|---|---|

₹ 2,319.00 | 2 Piece(s) | Available | 14 Day(s) | 10 | Closed End | 40 | [Glass Fiber] Glass Fiber | 1000 | 125 | |

₹ 2,645.00 | 2 Piece(s) | Available | 14 Day(s) | 10 | Closed End | 50 | [Glass Fiber] Glass Fiber | 1000 | 125 | |

₹ 4,130.00 | 2 Piece(s) | Available | 14 Day(s) | 10 | Closed End | 85 | [Glass Fiber] Glass Fiber | 1000 | 125 | |

₹ 1,470.00 | 2 Piece(s) | Available | 14 Day(s) | 10 | Closed End | 50 | [Glass Fiber] Glass Fiber | 416 | 52 | |

₹ 2,134.00 | 2 Piece(s) | Available | 14 Day(s) | 10 | Closed End | 85 | [Glass Fiber] Glass Fiber | 416 | 52 | |

₹ 4,544.00 | 2 Piece(s) | Available | 14 Day(s) | 10 | Closed End | 20 | [Glass Fiber] Glass Fiber | 4224 | 528 |

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy