(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

Shape

Round Shape Outer Dia. D (A)

Thickness T

Attraction Force (Specific)

Width

Length

type

Attraction Force (Range)

CAD

Days to Ship

Specification/Dimensions

-

Shape

-

Round

Round -

Square

Square

-

-

Round Shape Outer Dia. D (A)(Ø)

-

Thickness T(mm)

-

Attraction Force (Specific)(N)

-

Width(mm)

-

Length(mm)

-

type

- C-HXCC

- C-HXCR

- C-HXCS

-

Attraction Force (Range)(N)

- ~10.0

- 10.1~20.0

- 20.1~30.0

- 30.1~40.0

- 40.1~50.0

- 50.1~60.0

- 60.1~70.0

- 90.1~100.0

- 100.1~

-

CAD

- 2D

- 3D

Days to Ship

-

- All

- Same day

- 13 Day(s) or Less

Specify Alterations

Neodymium Magnets Countersunk with Holder and Screw

You can add up to 6 items per a category to the compare list.

Brand :

MiSUMi Economy

Part Number :

Copy Part Number URL to Clipboard

The part number URL has been copied into your clipboard.-

- Order Qty :

-

-

- Total Price :

- ---

-

- Days to ship :

- ---

Select part number to Order Now/ Add to Cart

Product Overview of Magnets with Holders

Overview of Magnets with Holders

A Magnets with Holders unit, which consists of a neodymium-iron-boron magnet, a metal case, copper rings, etc., is generally used to fix car roof lights, cabinets, door stops, and ceilings.

At present, domestic and foreign customers often use magnet units at the design level in automated machinery and equipment, which are relatively versatile and can be changed flexibly according to customer needs.

A Magnets with Holders unit, which consists of a neodymium-iron-boron magnet, a metal case, copper rings, etc., is generally used to fix car roof lights, cabinets, door stops, and ceilings.

At present, domestic and foreign customers often use magnet units at the design level in automated machinery and equipment, which are relatively versatile and can be changed flexibly according to customer needs.

Product Features of Magnets with Holders

FEATURES

| Neodymium Magnets with Holders | Neodymium magnets are the most powerful magnets of all, and are ideal for reducing size and increasing the performance of devices. The disadvantage is that it is very easy to rust. Cobalt magnet and it are known as rare earth magnets. |

| Cobalt Magnets with Holders | It is officially known as samarium cobalt magnet, with a strong magnetic force second only to neodymium magnet. Its advantage is being not prone to rusting and resistant to high temperature. But it has poor mechanical strength and is easy to be broken, so be careful when using. |

| Ferrite Magnets with Holders | Ferrite magnets have a weak magnetic force but relatively high retentivity, and magnetism is not easy to decay. It has poor mechanical strength and is easy to be broken, so be careful when using. |

| Al-Fe-Ni-Co Magnets with Holders | It has both the advantage of high temperature resistance and excellent mechanical strength. The disadvantage is that magnetism is very easy to attenuate. |

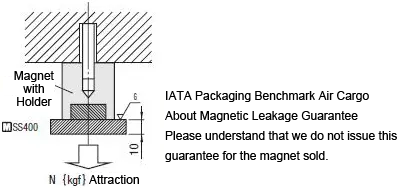

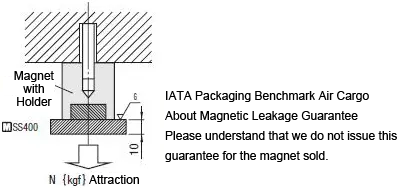

Dimensional Drawing of Magnets with Holders

Outline Dimensional Drawing of Magnets with Holders (Unit: mm)

Magnets with Holders are prone to chipping, so pay full attention when using.

Attraction Force and Surface Flux Density are reference values for Magnets with Holders alone.

Attraction Force and Surface Flux Density are reference values for Magnets with Holders alone.

Please visit MISUMI website for details of the models available for sale.

Please visit MISUMI website for details of the models available for sale.

Specification Table of Magnets with Holders

Magnets with Holders are prone to chipping, so pay full attention when using.

| Type of Magnets with Holders | A | T | d1 | H | d2 | d3 | t | B | P | Accessories (Stainless Steel Flat Head Bolts) | Attraction Force N{kgf} | Surface Magnetic Flux Density | |||

| Round Square | (Rectangular) | C-HXCC C-HXCC-S C-HXCCH | C-HXCS | C-HXCR | Gauss [G] | ||||||||||

| C-HXCC C-HXCC-S C-HXCCH (Round) C-HXCS (Square) C-HXCR (Rectangular) | 8 | 4 | 6.4 | 3.2 | 5.5 | 3 | 0.6 | 15 | 8 | M2.5-8×1 pcs | M2.5-8×2 pcs | 3.9{0.4} | 7.8{0.8} | 17.6{1.8} | 1200~3900 |

| 10 | 5 | 8 | 4 | 6.5 | 3.5 | 0.8 | 20 | 10 | M3-10×1 pcs | M3-10×2 pcs | 5.8{0.6} | 19.6{2.0} | 39.2{4.0} | 1500~4000 | |

| 12 | 6 | 9.6 | 4.8 | 6.5 | 3.5 | 1 | 25 | 12 | M3-10×1 pcs | M3-10×2 pcs | 15.7{1.6} | 29.4{3.0} | 68.6{7.0} | 3200~4000 | |

| 15 | 6 | 12.6 | 4.8 | 9 | 4.8 | 1 | 30 | 15 | M4-12×1 pcs | M4-12×2 pcs | 24.5{2.5} | 49.0{5.0} | 98.1{10.0} | 3800~4000 | |

| 20 | 7 | 17.2 | 5.6 | 11 | 5.8 | 1.2 | 40 | 20 | M5-16×1 pcs | M5-16×2 pcs | 58.8{6.0} | 127.5{13.0} | 230.5{23.5} | 3800~4000 | |

| 25 | 8 | 21.2 | 6.2 | 13 | 7 | 1.6 | 50 | 30 | M6-16×1 pcs | M6-16×2 pcs | 152.0{15.5} | 181.4{18.5} | 294.2{30.0} | 3700~4000 | |

Attraction Force and Surface Flux Density are reference values for Magnets with Holders alone.

Attraction Force and Surface Flux Density are reference values for Magnets with Holders alone. Please visit MISUMI website for details of the models available for sale.

Please visit MISUMI website for details of the models available for sale.Example Use of Magnets with Holders

| Example of Use ①Small PCB Soldering Fixture Magnets with Holders attraction is used to hold the harness Purpose & Operation A soldering fixture to hold the PCB with a side clamp, and hold the harness by attracting the cover with a magnet. Link address: //th.misumi-ec.com/en/asia/incadlibrary/detail/000074.html |  |

| Example of Use ②Free Angle Soldering Fixture Magnets with Holders Easy one-touch workpiece holding mechanism Purpose & Operation A fixture to securely hold the workpiece without clearance during welding operations. Soldering to positions with poor working efficiency. Link address: //th.misumi-ec.com/en/asia/incadlibrary/detail/000004.html |  |

Precautions of Magnets with Holders

All Magnets with Holders materials are very fragile, no alteration is available.

· Magnets with Holders may be damaged if they are subjected to strong impacts. Be careful during use.

· The magnetic field generated by magnets may cause adverse effects on the following items.

Electronic devices such as cell phones, computers, clocks and watches,

and electronic medical devices such as pacemakers.

·The magnetic force may deteriorate when used at above the maximum operating temperature.

· Strong impact or alteration on magnets may cause magnetic force losses.

· In order to avoid direct impact on the magnet, please keep the clearance of at least 0.1 to 0.3mm.

The adsorption force of powerful neodymium Magnets with Holders is about 30% higher than that of standard neodymium magnets. When taken out of the packaging bag, if there aremagnetic objects nearby, it may jump out and be sucked, causing the product to crack. Please be careful when using.

The adsorption force of powerful neodymium Magnets with Holders is about 30% higher than that of standard neodymium magnets. When taken out of the packaging bag, if there aremagnetic objects nearby, it may jump out and be sucked, causing the product to crack. Please be careful when using.Specifications Overview of Magnets with Holders

Usage Method of Magnets with Holders

Magnets with Holders Features

Load {kgf}=Load N×0.101972

●Don't apply alterations on magnets as they are fragile.

● Magnets with Holders may be damaged by strong impacts applied directly to the magnet surface.

● Magnets with holders have 0.1 to 0.3mm steps to protect the magnet surface from impacts.

● The magnet and holder are connected by adhesive.

“Attraction Force" indicates the power of lifting the mating material SS400 (polished surface of 10mm thick plate).

Load {kgf}=Load N×0.101972

●Don't apply alterations on magnets as they are fragile.

● Magnets with Holders may be damaged by strong impacts applied directly to the magnet surface.

● Magnets with holders have 0.1 to 0.3mm steps to protect the magnet surface from impacts.

● The magnet and holder are connected by adhesive.

“Attraction Force" indicates the power of lifting the mating material SS400 (polished surface of 10mm thick plate).

Part Number

- Incomplete part number.

Please use left hand selections to complete a part number.

Loading...

| Part Number |

|---|

| C-HXCC12 |

| C-HXCR8 |

| C-HXCS10 |

| Part Number | Price | Minimum Order Qty. | Volume Discount | Days to Ship | RoHS | Shape | Attraction Force (Range) (N) | Round Shape Outer Dia. D (A) (Ø) | Thickness T (mm) | Attraction Force (Specific) (N) | Width (mm) | Length (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

₹ 473.00 | 1 Piece(s) | Same day | 10 | Round | 10.1~20.0 | 12 | 6 | 15.7 | - | - | ||

₹ 823.00 | 1 Piece(s) | Same day | 10 | Square | 10.1~20.0 | - | 4 | 17.6 | 8 | 15 | ||

₹ 569.00 | 2 Piece(s) | 13 Day(s) | 10 | Square | 10.1~20.0 | - | 5 | 19.6 | 10 | 10 |

Loading...

Dimensional Drawing

(Unit: mm)

Specification Table

Magnets are prone to chipping, so pay full attention when using.

| Type | A | T | d1 | H | d2 | d3 | t | B | P | Accessories (Stainless Steel Flat Head Bolts) | Attraction Force N{kgf} | Surface Magnetic Flux Density | |||

| Round Square | (Rectangular) | C-HXCC C-HXCC-S C-HXCCH | C-HXCS | C-HXCR | Gauss [G] | ||||||||||

| C-HXCC C-HXCC-S C-HXCCH (Round) C-HXCS (Square) C-HXCR (Rectangular) | 8 | 4 | 6.4 | 3.2 | 5.5 | 3 | 0.6 | 15 | 8 | M2.5-8×1 pcs | M2.5-8×2 pcs | 3.9{0.4} | 7.8{0.8} | 17.6{1.8} | 1200~3900 |

| 10 | 5 | 8 | 4 | 6.5 | 3.5 | 0.8 | 20 | 10 | M3-10×1 pcs | M3-10×2 pcs | 5.8{0.6} | 19.6{2.0} | 39.2{4.0} | 1500~4000 | |

| 12 | 6 | 9.6 | 4.8 | 6.5 | 3.5 | 1 | 25 | 12 | M3-10×1 pcs | M3-10×2 pcs | 15.7{1.6} | 29.4{3.0} | 68.6{7.0} | 3200~4000 | |

| 15 | 6 | 12.6 | 4.8 | 9 | 4.8 | 1 | 30 | 15 | M4-12×1 pcs | M4-12×2 pcs | 24.5{2.5} | 49.0{5.0} | 98.1{10.0} | 3800~4000 | |

| 20 | 7 | 17.2 | 5.6 | 11 | 5.8 | 1.2 | 40 | 20 | M5-16×1 pcs | M5-16×2 pcs | 58.8{6.0} | 127.5{13.0} | 230.5{23.5} | 3800~4000 | |

| 25 | 8 | 21.2 | 6.2 | 13 | 7 | 1.6 | 50 | 30 | M6-16×1 pcs | M6-16×2 pcs | 152.0{15.5} | 181.4{18.5} | 294.2{30.0} | 3700~4000 | |

Attraction Force and Surface Flux Density are reference values for magnets alone.

Attraction Force and Surface Flux Density are reference values for magnets alone. Please visit MISUMI website for details of the models available for sale.

Please visit MISUMI website for details of the models available for sale.Material Specification

| Type | Shape | ① | ② | Heat resistant temperature | Magnet pole | |||

Material Material |  Surface Treatment Surface Treatment |  Material Material |  Surface Treatment Surface Treatment | Surface | Rear | |||

| C-HXCC | Round | SS400 Equivalent | Nickel Plating | Neodymium Magnet | Nickel Plating | 80℃ | N | S |

| C-HXCC-S | S | N | ||||||

| C-HXCCH | Heat Resistant Neodymium Magnet | 150℃ | N | S | ||||

| C-HXCS | Square | Neodymium Magnet | 80℃ | N | S | |||

| C-HXCR | Rectangular | Neodymium Magnet | 80℃ | N | S | |||

Basic Information

| Magnet Type (Material) | Neodymium Magnet | Holder Material | SS400 | Housing Surface Treatment | Nickel plated |

|---|---|---|---|---|---|

| Magnet Surface Treatment | Nickel plated | Magnetic Pole (Surface) | Pole N |

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Frequently asked question (FAQ)

- Question: Can alterations be made to MISUMI magnets?

- Answer: Magnets of any material are prone to breakage, so alterations cannot be made.

- Question: What are the types of MISUMI magnets?

- Answer: MISUMI magnets include neodymium magnets, cobalt magnets, ferrite magnets, Al-Fe-Ni-Co magnets.

- Question: How to arrange the magnetic force of MISUMI magnets from strong to weak?

- Answer: 1. Neodymium magnet 2. Cobalt magnet 3. Al-Fe-Ni-Co magnet 4. Ferrite magnet

- Question: How to arrange the strength of MISUMI magnets from strong to weak?

- Answer: 1. Al-Fe-Ni-Co magnet 2. Neodymium magnet 3. Ferrite magnet 4. Cobalt magnet

- Question: How to arrange the heat resistant temperature of MISUMI magnets from strong to weak?

- Answer: 1. Al-Fe-Ni-Co magnet 2. Ferrite magnet 3. Cobalt magnet 4. Neodymium magnet

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy