(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Please note that the MISUMI Pune office and warehouse will be closed on November 20th due to the state election.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

Specification/Dimensions

-

Cam Follower: Stud Screw (Fine Thread)(mm)

-

type

- C-CFFR

- C-CFR

- CFFRG

- CFRG

-

Outer Dia. D(Ø)

-

Width B(mm)

-

Stud Screw Nominal (M)(mm)

-

Allowable Rotational Speed(rpm)

-

Seal

- Not Provided

- Provided

-

CAD

- 2D

- 3D

Days to Ship

-

- All

- Same day

Specify Alterations

Cam Followers Straight Slot, Flat (Part Number)

- Volume Discount

Copy Part Number URL to Clipboard

The part number URL has been copied into your clipboard.-

- Order Qty :

-

-

- Total Price :

- ---

-

- Days to ship :

- ---

Select part number to Order Now/ Add to Cart

Economy Cam Followers

- Constructed from high-quality SUJ2 material. Ensures longevity and excellent wear resistance, making it suitable for demanding industrial applications.

- Incorporates needle rollers to enhance rotating capacity. Supports high-speed rotation, improving the overall efficiency of the bearing.

- Perfect for applications subjected to significant impact or heavy-duty use, ensuring reliable operation.

- Stud screw with multiple size options

- Available in various outer roller diameters and widths.

![]()

MISUMI Standard

![]()

Cheaper Price

![]()

Product Variety

![]()

3D CAD Support

Roller Followers Product Overview

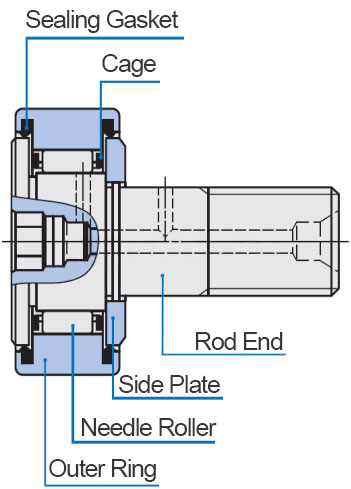

Cam follower is a high-performance bearing with shaft, which has a needle-shaped roller called needle roller mounted inside. The needle roller has the function of improving the rotating capacity and can withstand high-speed rotation. In addition, the outer ring is designed with a thicker wall than ordinary bearings, and can also be used in places subject to impact loads or heavy loads.

Roller Followers Product Feature

2. Ideal for places subject to loads!

3. Also suitable for high speed rotation!

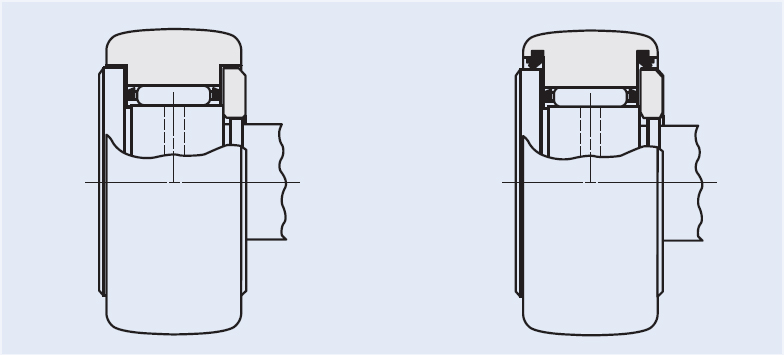

Standard Cam Follower Structure

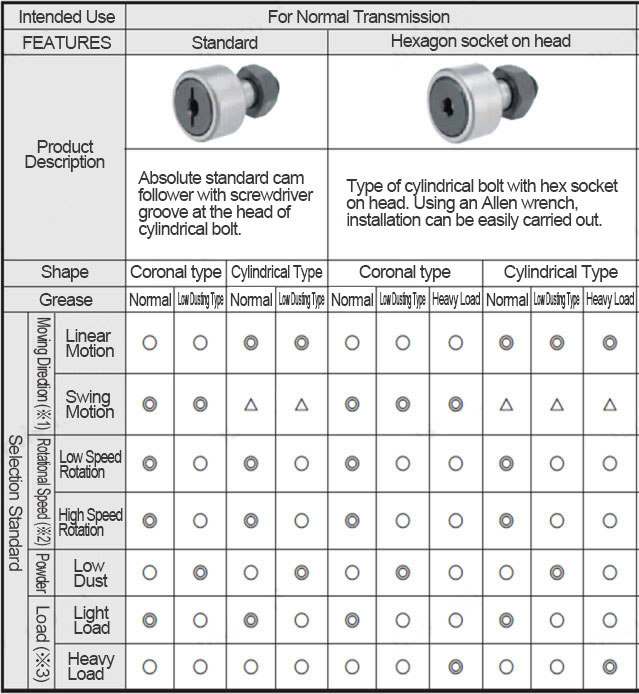

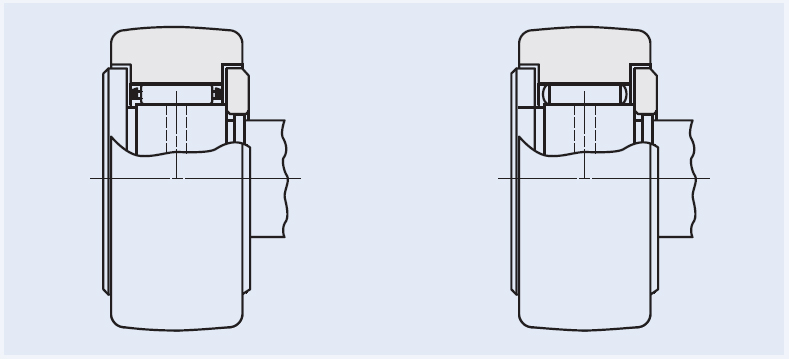

Roller Guide Mode

The cam follower with cage is suitable for applications with low friction coefficient and high rotation speed, and the full complement roller cam follower is suitable for applications with high rotation speed and heavy load.

Roller Followers Structure of Sealing Part

For the non-sealed type bearing, the gap between the outer ring and the end rod peripheral ring and between the outer ring and the side plate is small, thus forming a labyrinth. For the sealed type bearing, a sealing gasket is mounted in the shielded type labyrinth, thus preventing intrusion of foreign matter.

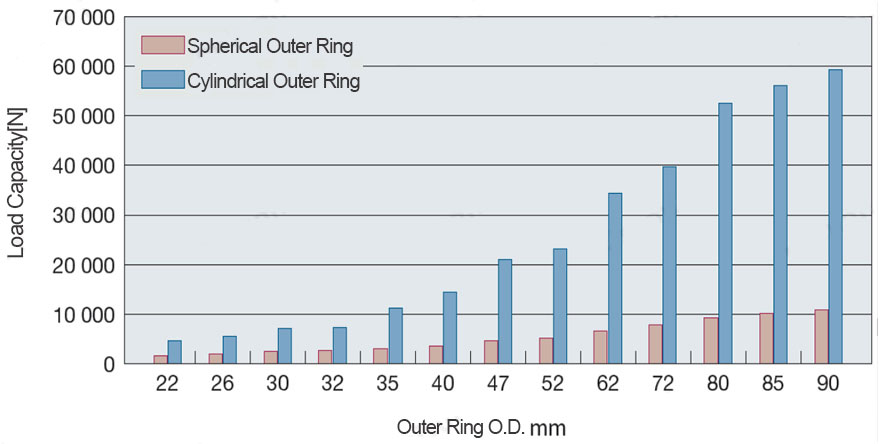

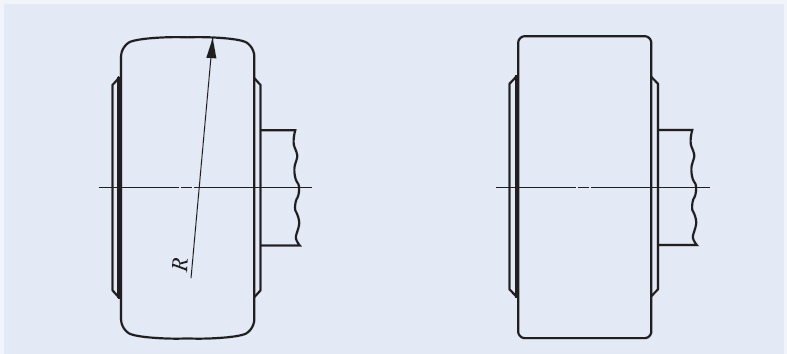

Roller Followers Outer Ring O.D. Shape

The bearing with spherical outer ring can alleviate uneven load caused by installation problems. The contact area between the bearing with arc outer ring and the slide rail surface is large, suitable for slide rail surfaces with large load or low hardness.

Slide Rail Load Capacity Comparison

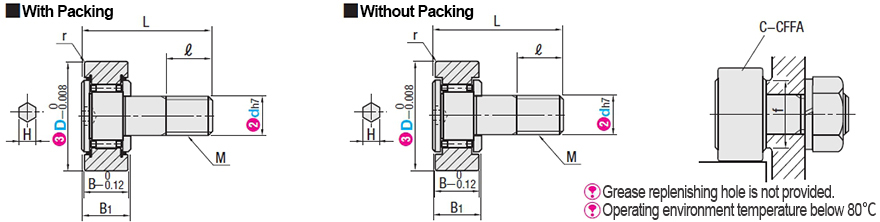

Roller Followers Dimensional Drawing

Cylindrical Shape

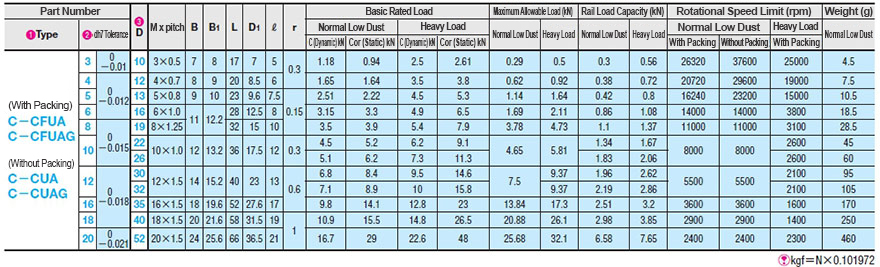

Roller Followers Specifications Overview

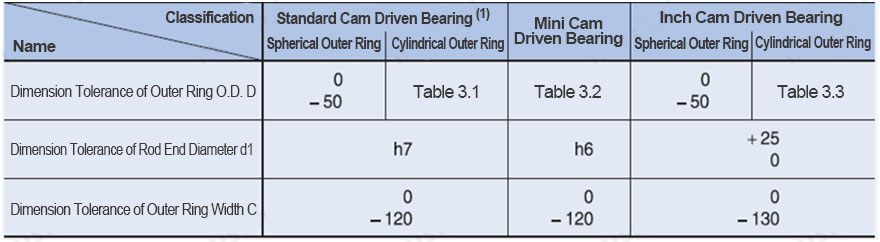

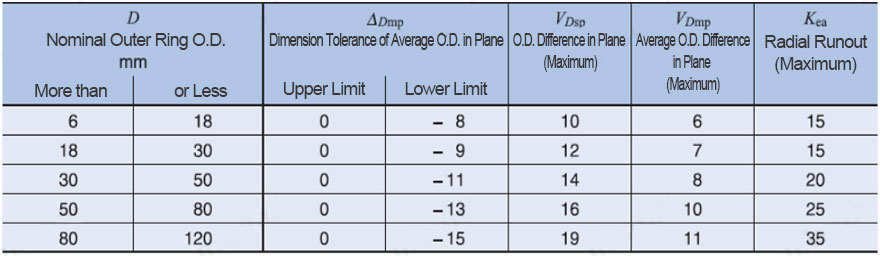

Allowable Tolerance

Allowable Tolerance of Outer Ring and Allowable Value

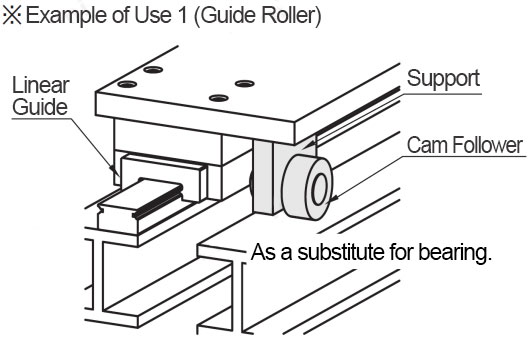

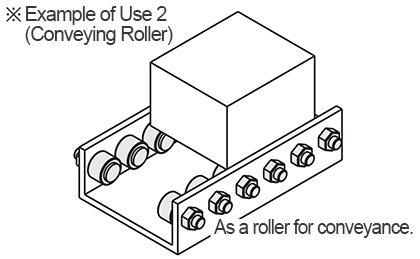

Roller Followers Example of Use

Linear Motion

The surface on the matching side must be flat

and the cam follower moves in a straight line

The surface on the matching side is curved, and

the cam follower moves in a curve

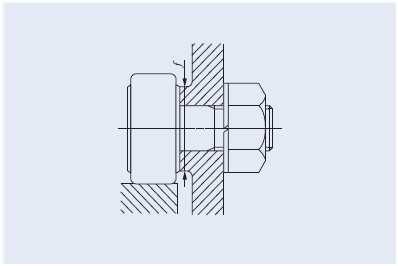

Do not use a hammer to directly hit the flange of the cam bearing during installation, otherwise it will cause poor rotation or fracture. Use a hex socket wrench or a slotted screwdriver.

Secure the hexagon socket or screwdriver slot for fixing, and then turn the nut with a wrench to tighten.

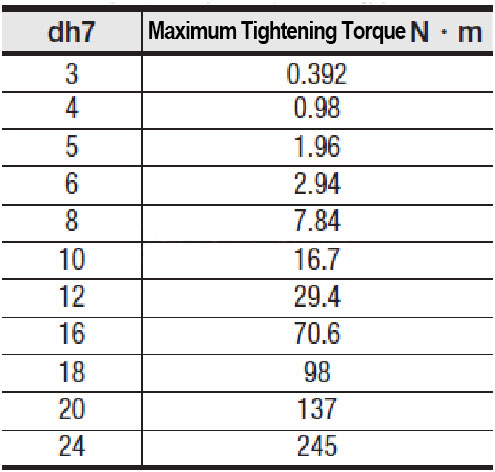

Bolt Tightening Torque

Do not exceed the maximum screw tightening torque when installing the cam follower. Otherwise, the threaded portion may be damaged.

Roller Followers Precautions

· Attention should be paid to the fact that impact can cause functional damage, even if it is not visible.

· Cam followers are suitable for radial loads and less suitable for thrust loads, so avoid using methods such as applying thrust loads.

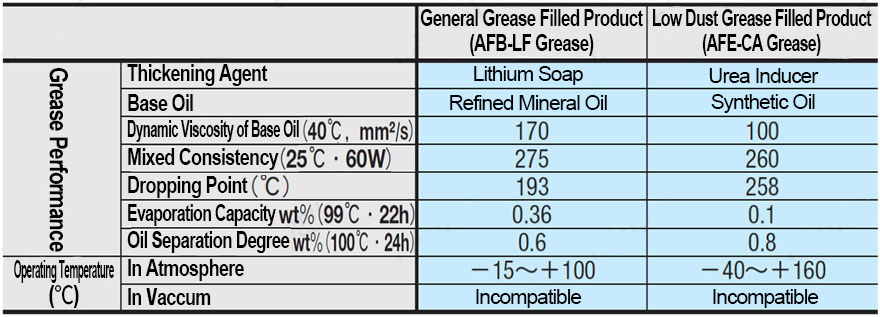

· Some cam followers are not filled with grease due to different sizes.

Please refer to the table below and add proper amount of grease to the products that are not filled with grease before use.

Cam Follower Grease Performance and Service Temperature

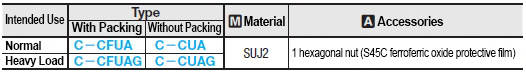

Part Number

- Incomplete part number.

Please use left hand selections to complete a part number.

| Part Number |

|---|

| C-CFR6-16 |

| C-CFRG6-16 |

| Part Number | Price | Minimum Order Qty. | Volume Discount | Days to Ship | RoHS | Outer Dia. D (Ø) | Width B (mm) | Stud Screw Nominal (M) (mm) | Cam Follower: Stud Screw (Fine Thread) (mm) | Basic Load Rating Cr (Dynamic) (kN) | Basic Load Rating Cor (Static) (kN) | Allowable Rotational Speed (rpm) | Seal |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

₹ 656.00 | 1 Piece(s) | Available | Same day | 10 | 16 | 11 | M6×1 | - | 3.15 | 3.3 | 14000 | Not Provided | |

₹ 1,461.00 | 1 Piece(s) | Available | Same day | 10 | 16 | 11 | M6×1 | - | 4.9 | 6.5 | 14000 | Not Provided |

Loading...

Basic Information

| Product Category | Cam Followers | Roller Type | Cylindrical Outer Ring | Tightening Method | Standard Type |

|---|---|---|---|---|---|

| Cam Follower Type | Standard Type | Size Standards | Metric System | Roller Lining | Not Provided |

| Shaft | Provided | Roller Guiding Method | With Retainer | Application | Regular |

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Frequently asked question (FAQ)

- Question: Mounting Method

- Answer: Do not use a hammer to directly hit the flange of the cam bearing during installation, otherwise it will cause poor rotation or fracture. Fix the inner hexagon or screwdriver slot with a hex socket wrench or a slotted screwdriver, and then turn the nut with a wrench to tighten. Do not exceed the maximum screw tightening torque when installing the cam follower. Otherwise, the threaded portion may be damaged.

- Question: Applicable load of cam follower

- Answer: It is applicable to radial load, but not very applicable to thrust load, so avoid using methods such as applying thrust load.

- Question: Usage difference of different O.D. shapes of outer ring

- Answer: The bearing with spherical outer ring can alleviate uneven load caused by installation problems. The contact area between the bearing with arc outer ring and the slide rail surface is large, suitable for slide rail surfaces with large load or low hardness.

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy