(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

Specification/Dimensions

-

Shaft Bore Dia. 1 d1 (or d)(Ø)

-

Shaft Bore Dia. 2 d2 (or d)(Ø)

-

O.D.(Ø)

-

Overall Length(mm)

-

Allowable Torque Range(N•m)

-

Allowable Torque(N•m)

-

Allowable Lateral Misalignment(mm)

-

type

- GSASL

-

CAD

- 2D

- 3D

Days to Ship

-

- All

- Same day

- 5 Day(s) or Less

- 6 Day(s) or Less

- 7 Day(s) or Less

Specify Alterations

Slit Couplings Long, Set Screw Type

- Volume Discount

Copy Part Number URL to Clipboard

The part number URL has been copied into your clipboard.-

- Order Qty :

-

-

- Total Price :

- ---

-

- Days to ship :

- ---

Select part number to Order Now/ Add to Cart

Product Description

Are economically priced with the quality/perforce kept to the same level as conventional products. Can serve as the substitute for CPL Type.

Coupling Product Overview

The parallel line coupling usually has 3 to 5 slots to deal with the problem of low torque rigidity.

The parallel line coupling takes into account the shortening of slots without weakening the ability to bear and correct deviation. Short slots can enhance and overlap the torque rigidity of the coupling, so that it can bear considerable torque.

Coupling Product Feature

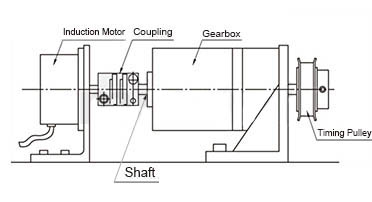

【Usage】Suitable for standard motors

【Precautions】Moment of inertia and weight are calculated at the maximum shaft dia.

【Type】Grooved type

【Body Material】Aluminum alloy

【Fixing System】Set Screw fixing type

【Applicable Motors】Servo motors and stepping motors

■ Parallel line couplings are suitable for light load applications.

Dimensional Coupling Drawing

| TYPE | [M]Material | [ S ] Surface Treatment | [ A ] Accessories |

| GSASL | Aluminum | Alumite Treatment | Set Screw |

Coupling Specification Table

Part Number ( Type· Type·  D) D) | - |  d1 d1 | - |  d2 d2 |

| GSASL20 | - | 6 | - | 8 |

| Part Number |  d1 d1 |  d2 d2 | L | ℓ | Set Screw | F | ||||||||||||||

Type Type |  D D | M (Coarse Thread) | Tightening torque (N·m) | |||||||||||||||||

| Set Screw GSASL | 8 | 2 | 2 | 3 | 14 | 3.5 | M3 | 0.3 | 1.7 | |||||||||||

| 3 | 3 | |||||||||||||||||||

| 12 | 3 | 3 | 4 | 5 | 18.5 | 2.5 | M2.5 | 0.5 | 5 | |||||||||||

| 4 | 4 | 5 | ||||||||||||||||||

| 5 | 5 | 6 | ||||||||||||||||||

| 16 | 4 | 4 | 5 | 6 | 23 | 6.4 | M3 | 0.7 | 3 | |||||||||||

| 5 | 5 | 6 | 8 | |||||||||||||||||

| 6 | 6 | 8 | ||||||||||||||||||

| 20 | 5 | 5 | 6 | 8 | 26 | 7 | ||||||||||||||

| 6 | 6 | 6.35 | 8 | 10 | ||||||||||||||||

| 6.35 | 8 | |||||||||||||||||||

| 8 | 8 | 10 | ||||||||||||||||||

| 10 | 10 | |||||||||||||||||||

| 25 | 6 | 6 | 8 | 10 | 31 | 8 | M4 | 1.7 | 4 | |||||||||||

| 6.35 | 8 | 10 | ||||||||||||||||||

| 8 | 8 | 10 | 12 | |||||||||||||||||

| 9.525 | 10 | |||||||||||||||||||

| 10 | 10 | 12 | ||||||||||||||||||

| 32 | 41 | 11 | 6 | |||||||||||||||||

| 8 | 8 | 12 | ||||||||||||||||||

| 10 | 10 | 11 | 12 | 14 | ||||||||||||||||

| 12 | 12 | 14 | ||||||||||||||||||

■Characteristic Value

| Part Number | Allowable torque (N·m) | Maximum rotational speed (rpm) | Moment of inertia (kg·m2) | Static torsional stiffness (N·m/rad) | Allowable lateral misalignment (mm) | Allowable Angular Misalignment ( ° ) | Allowable axial amplitude (mm) | Weight (g) | |

| Type | D | ||||||||

| GSASL | 8 | 0.1 | 10,000 | 1.2×10-8 | 25 | 0.1 | 2 | ±0.2 | 4.5 |

| 12 | 0.4 | 8.3×10-8 | 45 | ±0.3 | 6 | ||||

| 16 | 0.5 | 6.5×10-7 | 44 | ±0.4 | 9 | ||||

| 20 | 1 | 1.5×10-6 | 110 | 16 | |||||

| 25 | 2 | 4.2×10-6 | 215 | 0.15 | ±0.5 | 27 | |||

| 32 | 4 | 1.6×10-5 | 420 | 64 | |||||

| 40 | 8 | 3.2×10-5 | 700 | 0.2 | 134 | ||||

Coupling Precautions

1. The coupling allows axis deviation, and transmits rotation angle and torque, but when the axis deviation exceeds the allowable value, vibration will occur or the service life will be drastically reduced.

Be sure to make calibration and adjustment.

2. Axis deviation includes lateral misalignment (parallel error of two axes), angular misalignment (angular error of two axes) and axial amplitude (axial movement of shaft).

Please calibrate and adjust the shaft to ensure that the axis deviation is below the allowable value recorded in the dimension and performance table of each product.

3. The allowable value of axis deviation recorded in the dimension and performance table refers to the situation when either lateral misalignment, angular misalignment or axial amplitude occurs alone. When more than two axis deviations occur at the same time, the corresponding allowable values are halved respectively.

4. Axis deviation not only occurs when assembling to the device, but also is caused by vibration, thermal expansion and bearing wear in operation. Therefore, it is recommended to set the axis deviation below 1/3 of the allowable value.

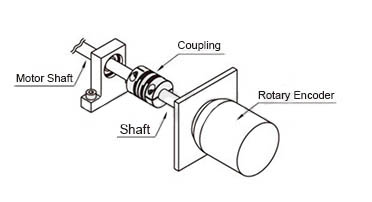

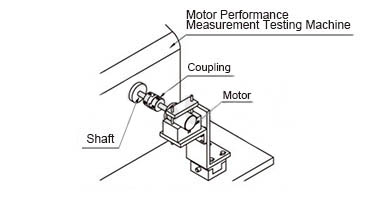

Example of Use coupling

Coupling Usage Method

STEP1 Insert the coupling

Confirm that the clamping bolt has been unscrewed, and then remove the dust, foreign matter and oil from the shaft and coupling bore.

Then, when inserting the coupling into the shaft, please be careful not to put the disc under excessive stress such as compression or tension.

STEP2 Use fixture to adjust

Please use fixture to adjust and fix the concentricity of the left and right hubs of the coupling with high accuracy.

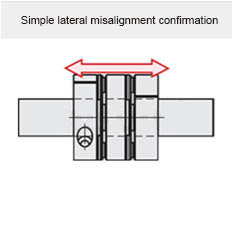

STEP3 Simple lateral misalignment and angular misalignment confirmation

Under the condition of unscrewed bolts, make the coupling slide axially and confirm its smooth movement.

Then, rotate the coupling to make sure it moves smoothly.

Lateral misalignment is not allowed for single disc type coupling, so carry out positioning securely.

STEP4 Installation

Please adjust the shaft insertion amount according to the dimension ℓ in the product catalog, and use a torque wrench to tighten with the specified torque.

* If the specified torque cannot be reached once, please cross fasten the left and right clamps twice or three times.

Part Number

- Incomplete part number.

Please use left hand selections to complete a part number.

| Part Number |

|---|

| GSASL12-3-3 |

| GSASL16-4-5 |

| GSASL16-5-5 |

| GSASL20-5-5 |

| GSASL20-6-6 |

| GSASL25-8-8 |

| GSASL32-8-8 |

| GSASL32-10-10 |

| GSASL32-10-11 |

| GSASL32-12-12 |

| Part Number | Price | Minimum Order Qty. | Volume Discount | Days to Ship | Shaft Bore Dia. 1 d1 (or d) (Ø) | Shaft Bore Dia. 2 d2 (or d) (Ø) | O.D. (Ø) | Overall Length (mm) | Allowable Torque Range (N•m) | Allowable Torque (N•m) | Allowable Lateral Misalignment (mm) | Allowable Axial Misalignment (mm) | Moment of Inertia (kg・m2) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

₹ 657.82 | 1 Piece(s) | Available | 7 Day(s) | 3 | 3 | 12 | 18.5 | 0.05~1.00 | 0.4 | 0.1 | 0.3 | 8.3×10-8 | |

₹ 1,402.56 | 1 Piece(s) | Available | 6 Day(s) or more | 4 | 5 | 16 | 23 | 0.05~1.00 | 0.5 | 0.1 | 0.4 | 6.5 x 10-7 | |

₹ 1,555.72 | 1 Piece(s) | Available | Same day | 5 | 5 | 16 | 23 | 0.05~1.00 | 0.5 | 0.1 | 0.4 | 6.5 x 10-7 | |

₹ 1,598.42 | 1 Piece(s) | Available | 7 Day(s) | 5 | 5 | 20 | 26 | 0.05~1.00 | 1 | 0.1 | 0.4 | 1.5×10-6 | |

₹ 1,568.12 | 1 Piece(s) | Available | 5 Day(s) | 6 | 6 | 20 | 26 | 0.05~1.00 | 1 | 0.1 | 0.4 | 1.5 x 10-6 | |

₹ 1,765.28 | 1 Piece(s) | Available | Same day | 8 | 8 | 25 | 31 | 1.01~3.00 | 2 | 0.15 | 0.5 | 4.2 x 10-6 | |

₹ 2,035.55 | 1 Piece(s) | Available | Same day | 8 | 8 | 32 | 41 | 3.01~5.00 | 4 | 0.15 | 0.5 | 1.6×10-5 | |

₹ 1,466.00 | 1 Piece(s) | Available | Same day | 10 | 10 | 32 | 41 | 3.01~5.00 | 4 | 0.15 | 0.5 | 1.6 x 10-5 | |

₹ 2,103.84 | 1 Piece(s) | Available | 6 Day(s) or more | 10 | 11 | 32 | 41 | 3.01~5.00 | 4 | 0.15 | 0.5 | 1.6 x 10-5 | |

₹ 2,275.73 | 1 Piece(s) | Available | 5 Day(s) | 12 | 12 | 32 | 41 | 3.01~5.00 | 4 | 0.15 | 0.5 | 1.6 x 10-5 |

Loading...

Basic Information

| Series Name | Slit | Application | For Servo Motors / Stepping Motor | Features | Zero Backlash / Low Moment of Inertia |

|---|---|---|---|---|---|

| Allowable Misalignment | Angular Misalignment / Eccentricity / Axial Misalignment | Max. Rotational Speed Range(r/min) | 4001~10000 | Body Material | Aluminum Alloy |

| Allowable Angular Misalignment(deg) | 2 | Product Category | Coupling Main Body | Allowable Lateral Misalignment Range(mm) | 0.02~0.2 |

| Max. Rotational Speed(r/min) | 10000 | Disc Material | Stainless Steel | Standard/Short | Standard Type |

| Shaft Bore Shape | Standard Bore | Shaft Tightening Method | Set Screw |

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Frequently asked question (FAQ)

- Question: What is a coupling?

- Answer: A coupling is a part that connects two different rotating bodies (motor shaft, ball screw, etc.) and aims at transmitting torque. The load of assembly adjustment is reduced by absorbing the axis deviation (lateral misalignment, angular misalignment and axial amplitude) between rotating bodies. And in case of accidental overload, the coupling is destroyed and the rotating bodies are disconnected to protect the expensive power part and the whole device.

- Question: What are the types of MISUMI couplings?

- Answer: There are disc type, grooved type, cross type, claw type, bellows type, rigid type and universal joint type.

- Question: How to select coupling according to motor?

- Answer: Disc type is recommended for servo motors, grooved type is recommended for stepping motors, and cross type is recommended for universal motors.

- Question: How to select according to the purpose, environment, working conditions?

- Answer: Please refer to the MISUMI website.

- Question: What kind of coupling should be used when the angular misalignment is very large?

- Answer: Please select the universal joint with allowable angular misalignment of 30 degrees. In addition, when grease cannot be applied regularly, use a rubber sleeve to fill grease and use it.

- Question: Which disc type coupling is better, single disc type or double disc type?

-

Answer:

Double disc type can absorb angular misalignment and lateral misalignment, but the total length will increase.

Although the total length of the single disc type is short, it is only suitable for applications with narrow space because lateral misalignment is not allowed in the structure. Special attention should be paid to centering during use. - Question: How much is appropriate to insert the shaft into the coupling during installation?

- Answer: Please select the length of the main body (coupling part) described in the product catalog. If the insertion amount is too short, the shaft may slip and the clamping part may be damaged; If the insertion amount is too long, it will be damaged due to shaft interference inside the coupling.

- Question: Why is it necessary to install a protection cover around the coupling?

- Answer: Due to high-speed rotation, accidental contact may result in injury or entanglement of gloves, towels, etc. In addition, for some reasons, parts may be damaged or debris may be scattered. Therefore, be sure to install the safety protection cover.

- Question: What should I do if there is no matching shaft bore diameter?

- Answer: Please select a product with changeable keyway width or available with keyway processing. MISUMI products are divided into MCSLCWK series (disc type), CPOC series (cross type) and MMJN series (claw type), etc.

- Question: Is it a defective product that has difference in groove gap width?

- Answer: Since the difference is within the dimensional tolerance range, there is no problem.

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy