(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

Flat Belt Pulleys(Shaft (Bore) Dia. d:8A)

Types of Flat Belt Pulleys

Flat belt pulleys are designed to transmit motion and power between shafts via flat belts, widely used in mechanical drives and conveying systems. These pulleys are offered in multiple shapes and structural variations to match specific performance requirements.

Shape Variants

- Flat Belt Pulleys – Straight: These have a flat, parallel surface ideal for standard flat belt applications, offering smooth and stable motion.

- Flat Belt Pulleys – Crowned: Crowned pulleys feature a slight convex surface that helps center the belt automatically, preventing slipping and improving belt alignment.

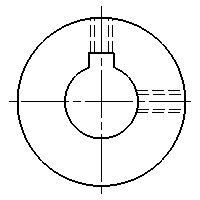

- Flat Belt Pulleys – V-Groove: Designed for applications needing additional grip, these pulleys combine flat belt function with V-groove positioning, often used in hybrid or custom systems.

Pulley Types

- Standard Pulleys: Used in power transmission systems to transfer rotary motion efficiently from one shaft to another.

- Idlers (Bearing Built-in): These pulleys come with built-in bearings and are typically used to guide or support belts without transferring torque. They help maintain belt tension and alignment.

Material Options

The choice of pulley material plays a crucial role in performance, durability, and application compatibility.

- Steel: Offers high strength and durability, suitable for heavy-duty industrial applications where high torque transmission is required.

- Aluminum: Lightweight and corrosion-resistant, aluminum pulleys are ideal for high-speed applications and reduce the overall weight of machinery.

- Stainless Steel: Known for its corrosion resistance and strength, stainless steel pulleys are ideal for cleanroom or harsh environment applications such as food processing or chemical equipment.

- Plastic: Lightweight and cost-effective, plastic pulleys are suitable for low-load and low-speed environments or where noise reduction is important.

Key Features and Applications

Flat belt pulleys are designed to provide efficient power transmission while minimizing wear and noise. Here are a few notable benefits and applications:

- Precision Performance: Ideal for precise, smooth, and continuous belt-driven motion.

- Wide Compatibility: Used in conveyors, machine tools, printing presses, and packaging equipment.

- Environment-Specific Variants: Pulleys are available in environmentally friendly designs and offer compatibility with moisture-sensitive or cleanroom environments.

- With or Without Flanges: Select flange types based on whether belt retention is needed.

Customization and Configuration

MISUMI and other featured brands offer flat belt pulleys in various diameters and face widths, with options for bore type, surface finish, and shaft mounting. Use the online configurator and CAD tools to select and tailor parts based on exact machine specifications.

Brand |

|

|---|---|

| CAD |

|

1 items

- Sort By

-

You can add up to 6 items per a category to the compare list.

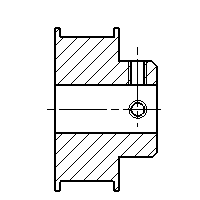

Idlers for Flat Belts-Straight Type/Crosspiece Groove Straight Type/Crowned Type/Width L110-500

MISUMI

New at MISUMI? Get 20% Discount on your First Purchase. Click to Register Now

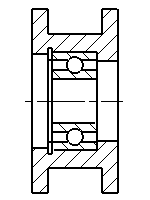

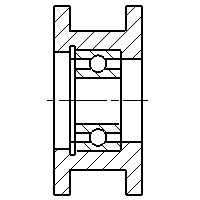

· Product type: Idlers.

· Idlers type: Bearing Built-in.

· Shape of Idlers: Straight type, Crosspiece Groove Straight Type and Crowned Type.

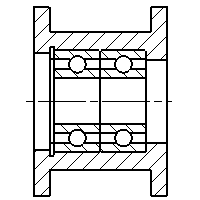

· Shaft Type : Bearing on Each End (2-Bearing in Total)

· The product code series Straight type: ROFAWC, ROFMWC and ROFSWC

· The product code series Crowned Type: ROFAWT, ROFMWT and ROFSWT

· The product code series Crosspiece Groove Straight: ROFAWM, ROFMWM and ROFSWM

· Outer Diameter: 30-80 mm.

· Shaft (Bore) Diameter: 8-35 mm.

· Length: 110-510 mm.

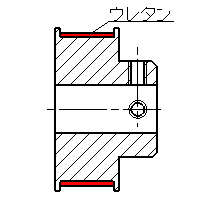

· Idler Engineering Plastic Roller, Steel Roller (TC-RP, TC-RU)Shape With or w/o Flange Outer Dia. D(Ø) Nominal Width T(mm) Length L(mm) Flange Shape Type Material Shaft Type Surface Urethane Shaft (Bore) Dia. d(mm) Surface Treatment Shaft End Specification Straight / Crowned No Flange 30 - ~300 / ~500 - Idlers (Bearing Built-in) Steel / Stainless Steel 1-Bearing on Each End (2-Bearing in Total) Urethane Not Provided 8A Not Provided / Electroless Nickel Plating - Days to Ship: 15 Day(s) or more  15 Day(s) or more

15 Day(s) or more

| Brand |

|---|

| Product Series |

| CAD |

| From |

| Days to Ship |

| Shape |

| With or w/o Flange |

| Outer Dia. D(Ø) |

| Nominal Width T(mm) |

| Length L(mm) |

| Flange Shape |

| Type |

| Material |

| Shaft Type |

| Surface Urethane |

| Shaft (Bore) Dia. d(mm) |

| Surface Treatment |

| Shaft End Specification |

You can add up to 6 items per a category to the compare list. | |

| Brand | MISUMI |

| Product Series | Idlers for Flat Belts-Straight Type/Crosspiece Groove Straight Type/Crowned Type/Width L110-500 |

| CAD |

|

| From | |

| Days to Ship | 15 Day(s) or more |

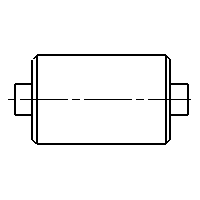

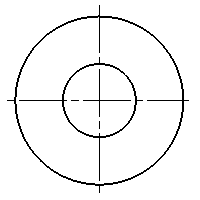

| Shape | Straight / Crowned |

| With or w/o Flange | No Flange |

| Outer Dia. D(Ø) | 30 |

| Nominal Width T(mm) | - |

| Length L(mm) | ~300 / ~500 |

| Flange Shape | - |

| Type | Idlers (Bearing Built-in) |

| Material | Steel / Stainless Steel |

| Shaft Type | 1-Bearing on Each End (2-Bearing in Total) |

| Surface Urethane | Urethane Not Provided |

| Shaft (Bore) Dia. d(mm) | 8A |

| Surface Treatment | Not Provided / Electroless Nickel Plating |

| Shaft End Specification | - |

Loading...

Configure

Specification/Dimensions

-

Shape

-

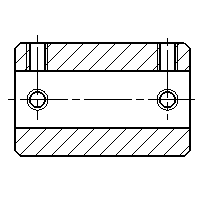

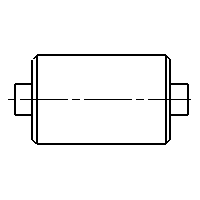

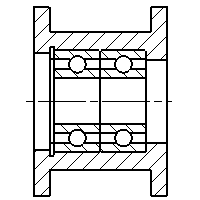

Straight

Straight -

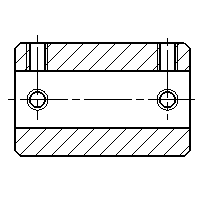

Crowned

Crowned -

V-Groove

V-Groove

-

-

With or w/o Flange

-

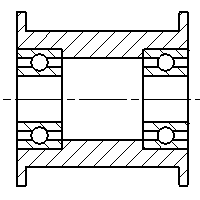

Flange

Flange -

No Flange

No Flange

-

-

Outer Dia. D(Ø)

-

Nominal Width T(mm)

-

Length L(mm)

- ~50

- ~100

- ~300

- ~500

-

Flange Shape

-

Type

- Idlers (Bearing Built-in)

- Pulleys

-

Material

- Steel

- Aluminum

- Stainless Steel

- Plastic

-

Shaft Type

-

Round Hole

Round Hole -

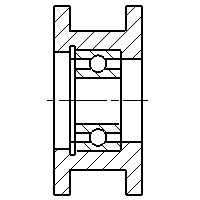

1-Bearing

1-Bearing -

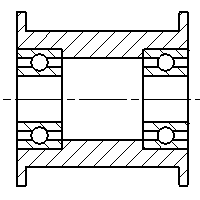

2-Bearing at Center

2-Bearing at Center -

1-Bearing on Each End (2-Bearing in Total)

1-Bearing on Each End (2-Bearing in Total) -

With Shaft

With Shaft

-

-

Surface Urethane

-

Shaft (Bore) Dia. d(mm)

-

Surface Treatment

-

Shaft End Specification

Related Categories to Flat Belt Pulleys

FAQ Flat Belt Pulleys

- Question: What are Flat Belt Pulleys and how are they used in machinery?

- Answer: Flat Belt Pulleys are mechanical drive components designed to transmit motion and power between rotating shafts using flat belts. They are commonly used in applications that require smooth and efficient power transmission, such as in conveyors, HVAC systems, packaging machinery, and other industrial automation setups.

- Question: What key factors should be considered when selecting a Flat Belt Pulley?

- Answer: Important selection criteria include outer diameter (D), nominal width (T), length (L), shaft compatibility (round bore or bearing type), and material (steel, aluminum, stainless steel, or plastic). The operating conditions—like load, speed, temperature, and environment—also significantly impact the ideal choice.

- Question: How does pulley shape affect performance in a flat belt system?

- Answer: The shape—such as straight, crowned, or grooved—determines how the belt tracks. Crowned pulleys self-center the belt to reduce slippage, straight pulleys offer precise alignment for tightly controlled setups, and grooved designs can provide better traction in specialized applications.

- Question: What role does a flange play on a Flat Belt Pulley?

- Answer: A flange helps to keep the belt aligned on the pulley and prevents it from slipping off during operation. Flanged pulleys are ideal in applications where lateral belt movement must be minimized for consistent and safe operation.

- Question: What materials are commonly used for Flat Belt Pulleys and why?

- Answer:

• Steel: High strength and durability for demanding loads

• Aluminum: Lightweight and corrosion-resistant, ideal for mid-load systems

• Stainless Steel: Excellent corrosion resistance, suitable for harsh or clean environments

• Plastic: Low weight, quieter operation, and cost-effective for light-duty use

- Question: How do I determine the right pulley diameter for my system?

- Answer: The ideal pulley diameter depends on the required speed and torque. Larger diameters increase belt speed but lower torque, while smaller diameters increase torque but reduce speed. Matching pulley size to your machine's performance specifications ensures efficient power delivery.

- Question: What advantages do idlers provide in flat belt systems?

- Answer: Idler pulleys, especially those with built-in bearings, help maintain proper belt tension, guide the belt’s path, and reduce vibrations and wear. They're essential for systems with long belt paths or direction changes.

- Question: Can Flat Belt Pulleys be customized for unique applications?

- Answer: Yes, many manufacturers offer customizations including material selection, surface treatment (e.g., anodizing, plating), and custom bore dimensions. Custom pulleys improve performance, fit, and longevity for specific use cases.

- Question: What is the effect of surface treatment on Flat Belt Pulley performance?

- Answer: Treatments like black oxide, nickel plating, or anodizing enhance corrosion resistance, reduce friction, and improve durability. These are particularly useful in high-humidity or chemically exposed environments.

- Question: How do I select the right bore diameter for a Flat Belt Pulley?

- Answer: The bore diameter must match the shaft size. Account for tolerances and any keyways needed for secure mounting. It should fit snugly—tight enough to prevent slipping but not so tight that it hampers installation or expansion due to heat.

- Question: What configuration options are available in terms of pulley length?

- Answer: Flat Belt Pulleys come in a range of lengths (e.g., short: ~50 mm, medium: ~100 mm, long: ~300 mm) to suit various belt widths and machine layouts. The length selected depends on belt travel and space constraints.

- Question: Why is pulley width important in flat belt systems?

- Answer: The pulley width must correspond to the belt width. A mismatch can cause slippage or uneven tracking, leading to reduced efficiency and potential damage. Proper width ensures stable operation and even belt wear.

- Question: What are common issues with Flat Belt Pulleys and how can they be avoided?

- Answer: Typical problems include belt slippage, misalignment, and excessive wear. These can be prevented with correct sizing, shape selection, regular maintenance, and using pulleys suited to the environmental conditions (e.g., corrosion-resistant coatings).

- Question: How does material choice affect pulley weight and system performance?

- Answer: Material directly influences weight—aluminum and plastic pulleys are lighter, which reduces system load and bearing wear. Steel and stainless steel offer strength but add weight, which may be a concern in high-speed or mobile systems.

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy