(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

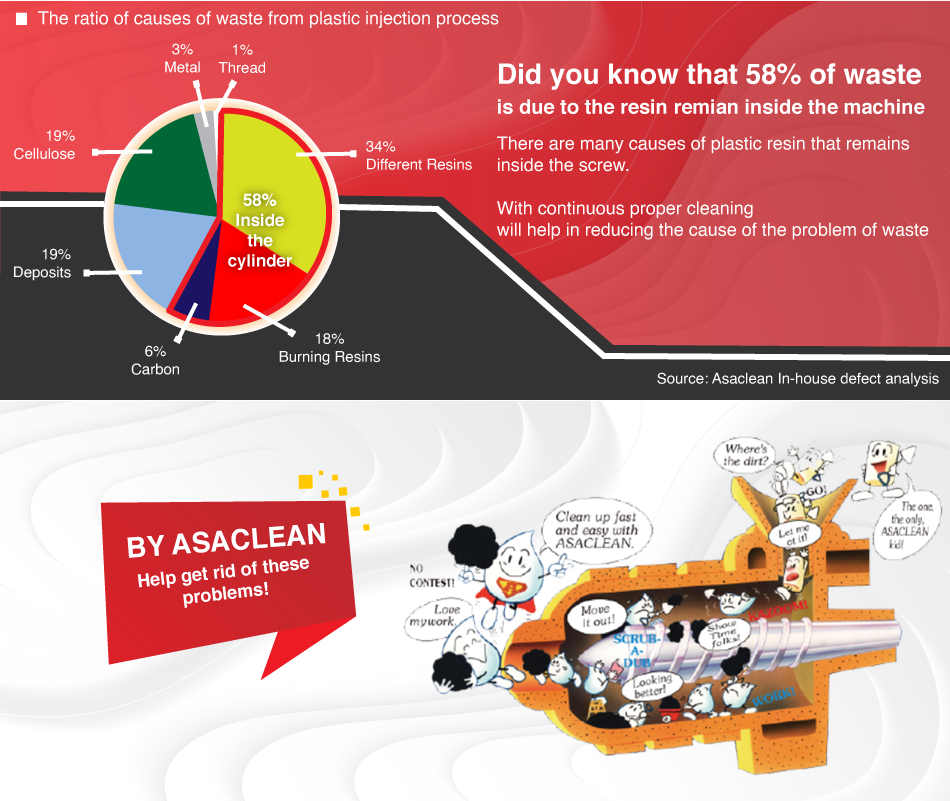

What type of parts cleaner are you using?

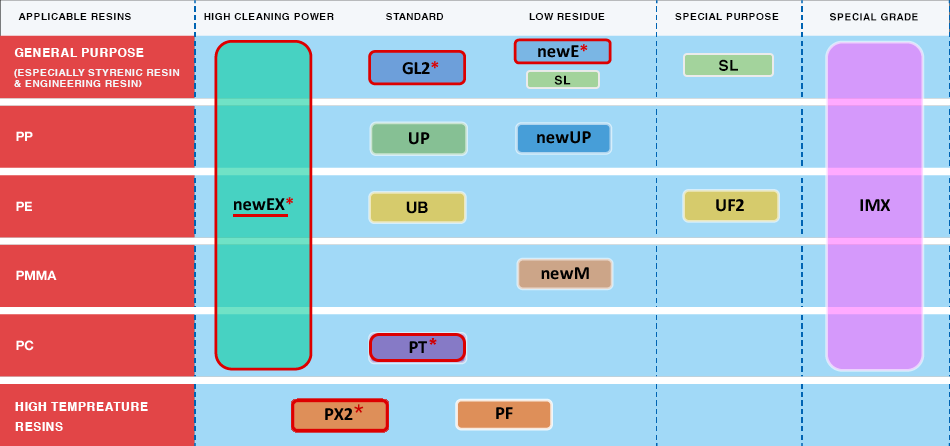

The cleaning power and residue characteristics of each Asaclean grade are relative to the resin category, as shown. Performance may vary due to the conditions and resin used.

Download SDS (Safety Data Sheet) here(PDF / 771KB)

Grades marked with * are stock products. You can use the Product Code in the table to request prices and order through the Web Ordering System.

Products without * mark are non-stock products. If you want to request a price or order, please contact at e-mail :cs@misumi.co.in

Note: Product NewEX and PX2 contain Fiber Glass.

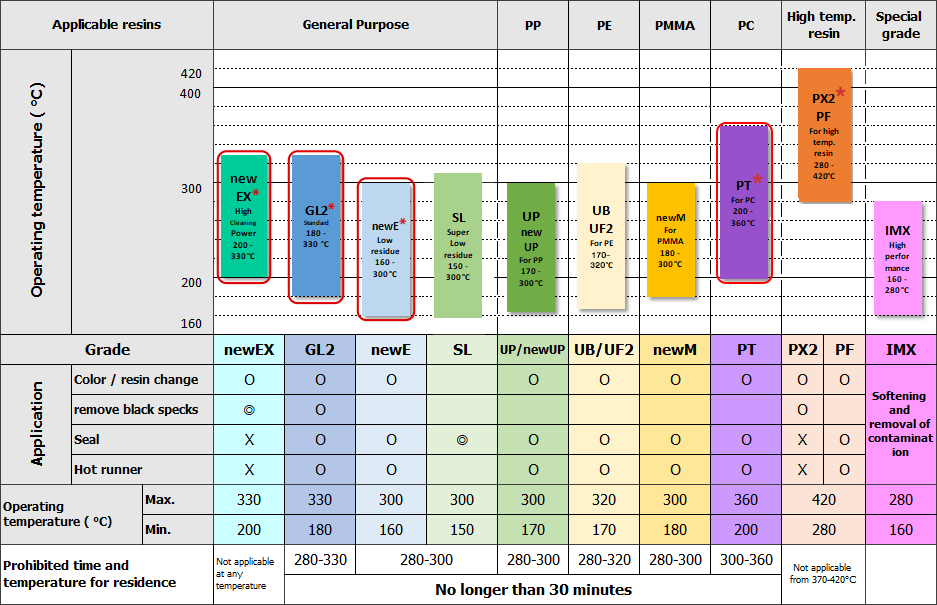

Operating Temperatures & Application

◎ : Excellent, O : Good, X : Not Applicable

※ Product lineup may be changed without notice.

※ Typical resin and usages applicable are shown above.

※ Strictly follow limitation of residence time and temperature.

Standard purging procedures

Main points of cleaning procedures

| Back pressure | High (enough so that the screw does not move back) |

|---|---|

| Screw position | Farthest forward position |

| Screw rotation speed | Same rotation speed as usual molding operation. |

| Temperature | Processing temperature for previous resin |

Purging procedure

- 1.Discharge previous resin entirely.

- 2. Clean the hopper before feeding Asaclean

- 3.Purge by screw rotation method

- 4.Visually check the discharge of previous color

- 5.Set the temperature for the next resin to be processed.

- 6.Clean the hopper before feeding next resin

- 7.Discharge Asaclean by screw rotation purge

- 8. Visually check the displacement of Asaclean.

- 9. Check the molded products

- The purging effect will decrease if previous resin remains. Confirm that nothing is left in the hopper and feeding line.

- Refer to the table below and estimate the quantity of Asaclean to use.

-

Back pressure: set higher; Screw position: farthest forward;

Screw rotation: same as molding; Temperature: same as previous resin - In the case of stopping machine, apply sealing procedures shown on page 4

- Change the temperature if necessary.

- Confirm that nothing is left in the hopper and feeding line.

- Perform in the same way as the purging operation.

- Confirm that Asaclean has been displaced entirely.

- Check the quality of the molded product.

Recommended amount of Asaclean

(1) By machine capacity

[Test condition]

Purging temperature: 240 ℃; Resin purged: ABS

| Clamping force (tons) | Quantity of Asaclean GL2(U) (kg) |

|---|---|

| 80 | 0.4 |

| 125 | 0.6 |

| 550 | 2.5 |

| 800 | 5.0 |

| 1,250 | 7.0 |

| 3,000 | 16.0 |

(2) by the operating temperature

[Test conditions]

Clamping force : 125 tons

| Molding temperature (℃) | Quantity of Asaclean GL2(U)(kg) | Resin (Example) |

|---|---|---|

| 180~230 | 0.4 | PS, PP, PMMA, POM And others |

| 230~250 | 0.6 | ABS, AS (SAN) And others |

| 250~310 | 0.8 | PA, PPE, PC, PBT, And others |

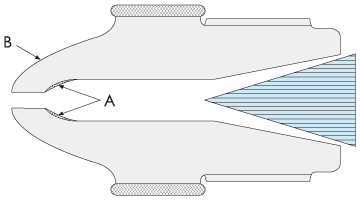

Purging methods for difficult-to-clean sections (How to purge tips sections)

The sections such as nozzle tip, screw head, long nozzle, valve nozzle, reflux valve, check ring and others, which are usually difficult to clean.

Insufficient cleaning of these sections may cause residue of previous resins or colors which leads contamination and defects of products.

In such cases, "Short-shot purge method" is recommended.

Part A: Dead spots

Part B: Cooled by mold and surrounding air

As section A is a low velocity regions and resins are easy to stay, such sections will be difficult to clean.

Main points of cleaning procedures

| Back pressure | 0 (zero) |

|---|---|

| Metering volume | Approximately 20 mm of screw stroke |

| Screw rotation speed | Same as molding operation |

| Injection speed | Increase injection speed by 20-30% higher than normal |

| Temperature | Raise the nozzle temperature by 20-30 ℃ |

Purging steps

- 1.Raise the nozzle temperature by 20-30℃

- 2. Meter approx. 20 mm.

- 3.Perform injection purging at high speed

- 4.Repeat procedure above 2 and 3 for 15-20 times.

- Softens the previous material stuck to dead spots so that they are removed easier.

- By metering small volume, increase the contact frequency of Asaclean to deposits.

- When inching injections is used together with screw rotation method, purging is more effective.

- Repeat these procedures until the previous resins entirely removed.

Note:

The following is the most recommended purging method.

1) "Screw rotation purge" By using the half of the recommended Asaclean volume

2) " Short-stroke purge" By using the rest of the recommended Asaclean volume

Purging and sealing methods

We recommend, "purging and sealing" togther with "routine purging". "Sealing" means turning off the machine power and having Asaclean fed in the barrel of the molding machine while it is stopped.

"Sealing" with Asaclean to prevent the progress of degradation of resins and ensures that the machine stays clean. Even if a small amount of resin is left in the machine during shutdown, degradation will progress due to high temperature and presence of oxygen. As a measure for preventing this, we recommend the method which the machine is stopped with Asaclean fed after purging by Asaclean.

Appropriate grade selection

Same Asaclean grade used for purging or Asaclean SL.

(Note) Asaclean grades(NewEX, CG, PX2) containing glass fibre must not be used for sealing.

Standard procedures for purging and sealing

- 1. All molding materials should be discharged after molding is completed.

- 2. Feed Asaclean and perform screw rotation purge.

- 3. Visually check that previous resin has been displaced.

- 4. Feed Asaclean in order to seal and discharge by screw-rotation purge.

- 5.Meter full shot volume

-

6.Stop the machine / turn off the heater (Or lower the temperature)

(Sealing)

- 7.Upon start-up, switch on the heaters(raise temperature)

- 8.Discharge full shot volume performed(Injection at low speed Or inching injection)

- 9.Displace Asaclean / re-purge

- 10.Feed next material and discharge by screw rotation purge.

- 11.Confirm the quality of the molded products.

- Fully discharge to allow for effective purging.

- Purge thoroughly to ensure that all resins is removed.

- In case of using NewEX, CG, PX2 or Asaclean GF Grade, discharge it with appropriate sealing grades (non-GF grades).

- Prevent entering oxygen from the nozzle tip. Do not leave Asaclean under the hopper in fed zone.

- Turn off the power of the machine, By turning off the heaters and cooling the machine, deposits stuck on the screw and barrel come off from metal surface due to shrinkage.

- In order to avoid the risk of overloading, start rotation of the screw when the temperature have been within operating temperature range of its grade. Change Asaclean to the next processing materials immediately after the temperature reaches presets temperature in case of starting up of machine or temperature changing.

- Keep your face away from the nozzle during injection.

- If the discharged Asaclean is very dirty, fed another Asaclean again and continue purging until it becomes its natural color.

- Confirm that Asaclean has been displaced entirely

- Confirm that molded products are good in quality.

Purging Frequency

Every time when molding machine is stopped.

Precautions for handling and use:

1) "Before using Asaclean, read the Safety Data Sheet (SDS) and the following precautions.

2) "Operating temperature differs depending on grades. Use within the specified temperature ranges.

3) "DO NOT allow newEX and CG to sit in the barrel for any period of time. Observe residence time allowed for the other grades.

4) "DO NOT use newEX, CG and PX2 for sealing.

5) "Screen packs (mesh) should be removed when purging extruders with glass-filled grades.

6) "Operators should wear appropriate protective equipment (safety glasses, face shields, gloves, etc.).

7) "Asaclean, same as other resins, is combustible and should be handled and stored in places away from heat and ignition sources.

8) "Dispose Asaclean in accordance with national and local laws and regulations.

9) "To prevent accidental falls or environmental hazard, immediately clean up spilled pellets and place them in proper waste container.

10) "If nozzle is clogged while purging, turn off the machine immediately and consult your machine manufacturer.

11) "Keep work area well ventilated as gas may be produced while purging.

12) "Handle purging scrap with care to prevent burns. Clear your surroundings from any flammable objects.

Contact Customer Service

Tel: +91-124-468-8800 (9:00AM - 5:30PM Monday to Saturday)

e-mail: CS@misumi.co.in (English Only)

日本語でのお問い合わせはジャパンデスクまで

Tel: +91-124-468-8808 (9:00AM - 5:30PM 月-金、9:00AM - 1:00PM 土)

e-mail: japandesk@misumi.co.in (Japanese Language Only)

Automation Components

Automation Components

Fasteners

Fasteners

Materials

Materials

Wiring Components

Wiring Components

Electrical & Controls

Electrical & Controls

Cutting Tools

Cutting Tools

Processing Tools

Processing Tools

Material Handling & Storage

Material Handling & Storage

Safety & General Supplies

Safety & General Supplies

Lab & Clean Room Supplies

Lab & Clean Room Supplies

Press Die Components

Press Die Components

Plastic Mold Components

Plastic Mold Components

Injection Molding Components

Injection Molding Components