Beyond the Pulse: Achieving Sub-Micron Accuracy with ORIENTAL MOTOR Stepping Solutions

Publish Date: 30 Oct 2025

In high-stakes automation, you can't afford to merely hope your component hits the target—you must guarantee it. Every professional engineer knows that system performance hinges on components that flawlessly convert digital commands into mechanical reality. At MISUMI India, we deliver this confidence by providing ORIENTAL MOTOR Stepping Motor solutions, built on absolute digital and mechanical certainty.

This is a deep technical look at the core physics, structural advantages, and advanced systems that make these stepper solutions the defining choice for achieving reliable, high-precision motion.

The Core Advantage: Digital Position Lock

The power of a Stepping Motor lies in its digital, non-cumulative error operation. It functions as an accurate electromechanical pulse counter, converting a sequence of electrical pulses into fixed, discrete angular movements.

Internal Structure: Rotor and Stator

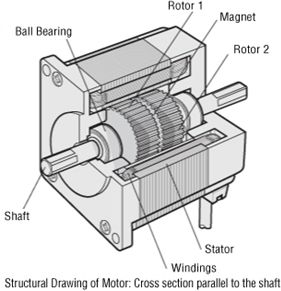

Broadly, a stepper motor is composed of two main parts: the stator and the rotor.

- Rotor: Consists of three parts: Rotor 1, Rotor 2, and an axially magnetized permanent magnet placed between them. Rotor 1 is typically magnetized as the North pole, and Rotor 2 as the South pole. Crucially, the outer periphery of the rotor has numerous small teeth (e.g., 50), and the teeth of Rotor 1 and Rotor 2 are mechanically offset by half a pitch.

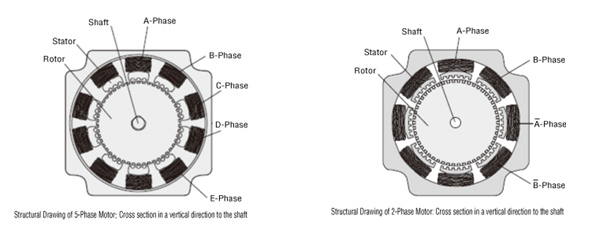

- Stator: Features magnetic poles with corresponding small teeth and is wound with coils. Opposing magnetic poles are connected and wound such that when current flows (excitation), they magnetize to the same polarity (either North or South). These opposing poles form a single phase.

The number of phases defines the motor type: a 5-phase stepper motor (Phase A to E) or a 2-phase stepper motor (Phase A and B).

Precision is Proportional

The motor's position and velocity are not inferred from feedback; they are directly commanded by the input signal frequency and count.

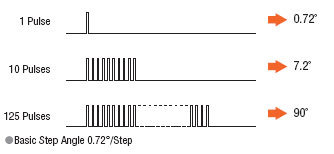

- Rotation Angle (θ): Is strictly proportional to the Number of Pulses (A) supplied, guaranteeing position accuracy:

Where θS is the Step Angle. ORIENTAL MOTOR’s options include the high-resolution 5-Phase Stepper with a base step of 0.72∘ and the versatile 2-Phase at 1.8∘. Choosing a High-Resolution Type effectively doubles this native resolution, significantly reducing mechanical vibration and settling time.

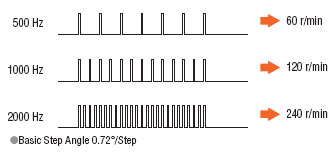

- Rotation Speed (N): Is directly proportional to the Pulse Frequency (f in Hz). This linear relationship simplifies velocity profile generation and ensures stable low-speed operation—a frequent pain point for other motor types.

Static Stability: The Holding Force

A critical engineering benefit is the stepper's intrinsic holding force when energized but stopped. This means the motor inherently resists external forces and maintains the final stop position without relying on external mechanical components, leading to simpler, lower-cost, and more reliable machine designs.

Overcoming Mechanical Inertia and Gravity

ORIENTAL MOTOR designs are specifically engineered to manage high inertial loads and gravity-dependent systems.

1. Superior Inertia Management

Stepping motors exhibit a surprising capacity to effectively control and accelerate high-inertia loads relative to their size.

- Inertia Capacity: They are often capable of driving loads with inertia up to 30 times the rotor inertia, offering a highly robust solution compared to servo motors, where the load-to-rotor inertia ratio must often be kept much lower for stable tuning.

2. The Power of Geared Systems: Torque and Damping

Integrating a dedicated, low-backlash gearhead enhances torque output and system dynamics:

- Torque Augmentation & Miniaturization: Geared types multiply the available holding torque, allowing engineers to select a smaller frame size motor to meet the torque requirement, facilitating equipment miniaturization and mass reduction.

- Damping and Stability: The permissible load inertia increases proportional to the square of the gear ratio. For instance, a 5:1 gear ratio can handle 25 times the inertia of the standard motor, critically improving damping characteristics and allowing for faster, more stable positioning cycles with heavy or oversized loads.

- Direct Load Integration: Harmonic and HPG Geared Types allow for direct coupling of the load to the output flange, eliminating couplings, reducing parts count, and providing superior rigidity to handle moment loads, as needed for high-precision Index Tables.

3. Safety for Vertical Loads (Electromagnetic Brake Type)

For gravity-fed or vertical mechanisms (like lifts, vertical stockers, or Z-axes), the Electromagnetic Brake Type is a necessary safety feature. This is a power-off activated brake that ensures the load is locked immediately upon power failure, preventing catastrophic free-fall due to the loss of the motor’s self-holding force.

Smart Integration: Driver Architectures for Industry 4.0

The choice of driver determines the motor's intelligence and network compatibility. ORIENTAL MOTOR offers intelligent solutions for modern control topologies:

| Driver Type | Control Method | Key Technical Application |

|---|---|---|

| Pulse Input Type | Traditional control via external Pulse Generator/Positioning Module. Includes RS-485 for monitoring (AZ Series). | High-speed, highly deterministic positioning where the host controller manages motion profiles. |

| Built-In Controller Type (FLEX) | Stores motion data locally. Executes commands via I/O, Modbus (RTU)/RS-485, or Industrial Networks (via converter). | Decentralized control, reducing PLC load; ideal for complex sequential moves executed remotely. |

| Network Compatible Driver | Direct communication via EtherNet/IP and EtherCAT. | Single-cable installation for power and network; superior diagnostics, rapid system integration, and reduced wiring complexity. |

| Encoder Type | Provides position monitoring capabilities. | Allows for comparison between commanded position and actual position, enabling error detection and enhancing the reliability of open-loop systems. |

Your Technical Partner: MISUMI India

At MISUMI India, we understand that sourcing complex motion control components needs to be as efficient as the components themselves. We provide the essential link to ORIENTAL MOTOR’s technology:

- Reliable Sourcing: Dependable access to the complete technical portfolio, including standard, high-torque, encoder, and diverse geared motor options.

- Simplified Procurement: Competitive pricing and highly efficient logistics, reinforced by Free Delivery with No Minimum Order, ensuring your project timelines are met without inventory barriers.

- Consultative Support: Our technical resources are available to assist in system optimization, ensuring you select the motor and driver configuration best suited for your specific inertia and torque curves.

Leverage the engineered precision of ORIENTAL MOTOR and the efficiency of MISUMI India to gain a decisive technical advantage in your next automation build. Don't just move your load—control it digitally.