Belt Conveyors: The Most Reliable Link in Modern Manufacturing

Publish Date: 30 Oct 2025

Belt conveyors are the most widely used conveying systems in industrial operations. They are designed to move a broad range of materials efficiently from one point to another. The principle is simple—materials are placed on a moving belt, which transports them along a predetermined path. Depending on the layout of the facility, these belts can operate horizontally, on an incline, or even along curved routes.

Because of their reliability and adaptability, belt conveyors are often used as connecting links between different stages of a manufacturing process. They support continuous and high-speed production, helping increase output while keeping operational costs low. This combination of efficiency and cost-effectiveness makes them a preferred choice for modern industrial systems.

The Blueprint for Selection: Key Principles for Choosing a Conveyor Belt

Selecting the right conveyor isn't a guesswork; it's a precise engineering decision. To ensure maximum efficiency and suitability for your specific application, you must consider four critical factors:

1. Materials to be Transported (Work Piece)

The nature of the item being moved dictates the conveyor's design. You must first determine the material type, size, and shape. Are you moving small, delicate electronics or large, abrasive quarry stones? This fundamental information will heavily influence the choice of belt material, surface texture, and the overall design specifications.

2. Required Production Volume (Capacity)

Capacity is the measure of the job's scale. Defining the required production volume helps determine the appropriate specifications for the entire system, including:

- The necessary width and length of the belt.

- The size and durability of the load-bearing support structure.

- The required speed of the belt's movement.

3. Direction and Manner of Transport (Direction)

Conveyors aren't just straight lines. Depending on the worksite and the process requirements, your belt may need to execute various movements, such as straight horizontal travel, inclined (upward or downward) movement, curved paths, or even vertical spiral conveying.

4. Operating Environment

The environment is a silent factor that significantly impacts a conveyor's lifespan and performance. You must account for factors like:

- Humidity or Corrosive Agents: Environments like food or pharmaceutical processing require stainless steel structures and specialized food-grade belts to maintain cleanliness and resist corrosion.

- Temperature: High-heat applications (like ovens) require heat-resistant materials, while cold environments may affect belt flexibility.

- Chemical Exposure: Industries dealing with petroleum or lubricants might need belt coatings like NBR rubber for superior resistance.

Exploring the Common Types of Conveyor Belts

Conveyor technology offers a specialized belt for almost every industrial requirement:

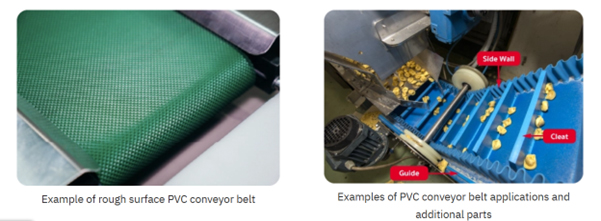

1. PVC Belt Conveyor

The workhorse of light industry, PVC (Polyvinyl Chloride) belts feature a PVC top surface and a nylon fabric base. They are highly versatile, offering various surface patterns (smooth to rough). They are relatively inexpensive and ideal for lightweight applications, operating up to $80^{\circ}$C. Due to their moderate chemical resistance and low cost, they are a perennial favorite across most industries.

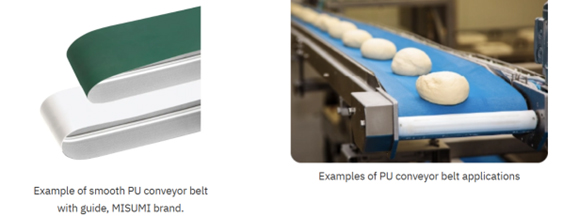

2. PU Belt Conveyor

For a step up in performance, PU (Polyurethane) belts offer a similar structure to PVC but with a smoother surface and higher performance properties. They boast better abrasion resistance, tolerate temperatures up to $100^{\circ}$C, and have superior chemical resistance. Though more expensive, their high durability and hygienic properties make them the go-to choice for the food industry.

3. Black Rubber Conveyor Belt (Rubber Belt)

When the going gets tough, the Black Rubber Belt takes over. Made from natural (NR) or nitrile (NBR) rubber, these are built for heavy-duty applications that demand high load capacity, excellent shock absorption, and extreme abrasion resistance. They are customized with properties like heat, oil, or chemical resistance and are indispensable in heavy industries like stone crushing, mining, and metal smelting.

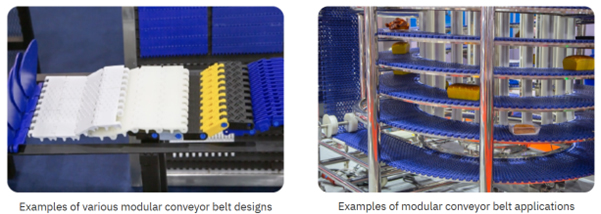

4. Modular Belt Conveyor

These modern belts are constructed from injection-molded engineering plastics (like PE, PP, or POM) linked together like a chain. They offer high strength, low elongation, and exceptional resistance to water, oil, and chemicals. Modular belts are increasingly replacing PVC/PU systems due to their long service life, representing a valuable long-term investment often seen in the food, automotive, and electronics sectors.

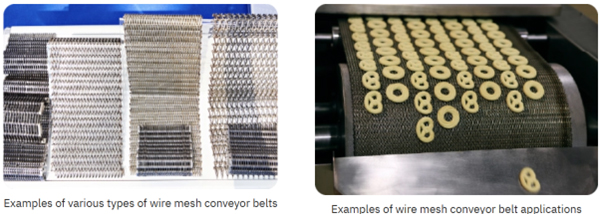

5. Wire Mesh Belt Conveyor

For processes involving thermal treatment, the Wire Mesh Belt is essential. Constructed from woven steel or stainless steel wires, they allow for customizable mesh spacing. This design is perfect for processes that require heat (baking), cooling, or washing, as it allows air, water, or oil to pass directly through the belt.

Before making your final choice, meticulous research is paramount. Ensuring your selected conveyor meets the specific demands of your materials and environment is the key to maximizing efficiency and securing a truly worthwhile investment.