The Essential Role and Mechanics of Bearings

Publish Date: 30 Oct 2025

Every time a machine spins—from a powerful jet engine to the small motor in your blender—a seemingly simple component is working tirelessly behind the scenes: the bearing. Far from being a mere piece of hardware, a bearing is the linchpin of rotational efficiency, turning harsh friction into smooth, predictable motion. Without them, shafts would grind to a halt, machines would overheat, and modern technology wouldn't operate as we know it.

Bearings are fundamental mechanical components crucial for supporting shaft movement, ensuring precise and efficient operation in rotating machinery. Their primary function is threefold: to support a load (weight), to transfer force generated by a rotating shaft or device, and critically, to minimize friction between contact surfaces. This allows the shaft to rotate smoothly and efficiently in both radial (perpendicular to the shaft) and axial (parallel to the shaft) directions.

Core Components of a Bearing

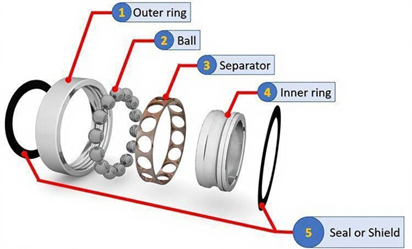

A typical bearing assembly consists of several key parts that work together to manage load and reduce friction:

- Outer Ring: The exterior component that houses and supports the internal rolling elements.

- Inner Ring: The internal component that typically fits onto the shaft and prevents direct contact between the shaft and the rolling elements.

- Ball or Roller (Rolling Elements): These are the critical elements—spheres or cylinders—that bear the weight and facilitate the low-friction rotation.

- Separator or Retainer: This cage maintains equal spacing between the rolling elements and prevents them from rubbing against each other.

- Seal or Shield: Protective covers used to prevent contaminants (like dust or debris) from entering the bearing assembly, which is essential for maximizing its lifespan.

Classification and Key Types of Bearings

Bearings are broadly classified based on the shape of their internal rolling elements: Ball Bearings (which use spherical elements) and Roller Bearings (which use cylindrical or shaped elements).

1. Ball Bearings

Ball bearings utilize spherical balls that roll between the inner and outer rings. Made of hard metal, they are commonly used in high-speed applications and are excellent at handling radial loads.

- Deep Groove Ball Bearings: The most common type, capable of handling both significant axial and radial forces.

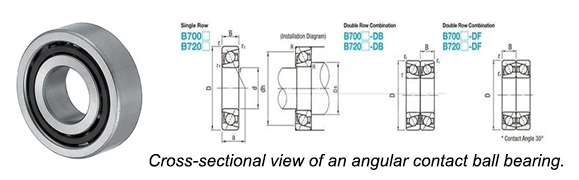

- Angular Contact Ball Bearings: Designed for combined radial and axial loads. They offer various contact angles (e.g., 15∘,25∘,30∘); a greater angle increases the axial load capacity but decreases the radial capacity.

- Self-Aligning Ball Bearings: Feature a curved outer ring raceway, making them ideal for machinery where shaft misalignment is a concern.

- Thrust Ball Bearings: Specifically engineered to manage pure axial loads. They are not recommended if radial forces are also present.

2. Roller Bearings

Roller bearings use cylindrical or shaped rollers, which provide a larger contact area than balls. This makes them significantly more effective than ball bearings at handling higher radial forces and heavier loads.

- Cylindrical Roller Bearings: Excel at withstanding high radial loads but have limited axial load capacity.

- Taper and Spherical Roller Bearings: These are robust designs capable of managing both high radial and high axial loads simultaneously.

- Needle Roller Bearings: Similar to cylindrical roller bearings but use very long, thin rollers, making them the perfect choice for applications with limited radial space.

Understanding these fundamental distinctions and their specific load-handling capabilities is essential for selecting the appropriate bearing to ensure peak mechanical efficiency.

What to Consider When Installing Bearings for Maximum Efficiency

Now that we've covered what bearings are and their various types, let's look at the crucial factors for installing bearings to ensure they operate at maximum efficiency and achieve their intended lifespan. Proper installation is just as critical as selecting the right bearing.

1. Preparing the Shaft and Housing

The surfaces the bearing contacts must be meticulous:

- Cleanliness: Both the shaft and the bearing housing bore must be perfectly clean and free from dust, debris, or old lubricant. Contaminants are a leading cause of premature bearing failure.

- Dimensional Accuracy: Ensure the shaft and housing adhere to the specified tolerances. If the fit is too loose, the bearing might creep or slip; if it's too tight (excessive interference), it can generate harmful internal stresses and reduce the bearing's clearance.

2. Choosing the Right Installation Method

Bearings should never be hammered directly as this can damage the rings and rolling elements. The installation method should apply force evenly to the ring being press-fitted:

- Mechanical Press/Press-Fitting: For smaller bearings, a controlled press is used to apply pressure to the ring that is being fitted (the inner ring for a shaft, the outer ring for a housing).

- Heating (Thermal Fitting): For medium to large bearings, the inner ring is often heated (using induction heaters or oil baths) to expand it slightly before sliding it onto the shaft. This allows for a smooth, stress-free installation.

- Hydraulic Tools: For very large bearings, specialized hydraulic equipment may be used to apply force or inject oil to facilitate fitting.

3. Proper Lubrication

Applying the correct amount and type of lubricant is foundational to bearing efficiency:

- Initial Lubrication: Before or immediately after installation, the bearing must be lubricated with the specified grease or oil. This lubricant creates a film that separates the rolling elements and raceways, preventing metal-to-metal contact.

- Lubricant Type: Always use the lubricant type recommended by the manufacturer, considering factors like operating temperature, speed, and load. Mixing incompatible lubricants can lead to breakdown.

- Amount: Too little lubrication causes friction and overheating; too much can lead to excessive heat generation and churning, which wastes energy.

4. Alignment and Sealing

Applying the correct amount and type of lubricant is foundational to bearing efficiency:

- Alignment: For two bearings on the same shaft, or for bearings in self-aligning applications, ensure the alignment is precise. Misalignment dramatically increases friction and wear, particularly edge loading on the rollers or balls.

- Seals and Shields: Ensure the seals or shields are correctly positioned and intact to maintain the internal cleanliness of the bearing and retain the lubricant.

By strictly adhering to these installation practices, you can maximize the performance, reliability, and service life of your ball and roller bearings.