Everything You Need to Know About the Ball Screw

Publish Date: 16 Oct 2025

Have you ever stopped to wonder how massive industrial machinery executes incredibly precise movements? From high-speed 3D printers to multi-axis CNC machines, the secret often lies in a powerful yet precise component: the Ball Screw. This device is the unsung hero that translates rotational motion into smooth, highly accurate linear motion.

Many engineers and designers have seen this critical hardware, but few fully grasp the clever mechanics behind its operation and the importance of selecting the right type. Let's delve into the world of the ball screw and discover what makes it indispensable in modern automation.

What is a Ball Screw and How Does it Work?

At its core, a Ball Screw is a highly efficient mechanical actuator that converts rotary motion into linear motion. It functions by allowing recirculating ball bearings inside a nut to roll along precision-machined grooves on a screw shaft. This rolling action is what sets it apart.

Instead of the high friction (and inevitable wear) found in traditional lead screws, the ball screw utilizes the rolling motion of the balls to achieve a remarkably low coefficient of friction. This efficiency allows for:

- High-Speed Operation: Minimal resistance means faster travel.

- Minimal Wear:Reduced friction extends the life of the system.

- High Load Capacity: The large contact area of the rolling balls can handle heavy loads.

The varying paths the ball bearings take within the nut define the screw's performance, size, and application suitability.

Anatomy of a Ball Screw: Structure and Function

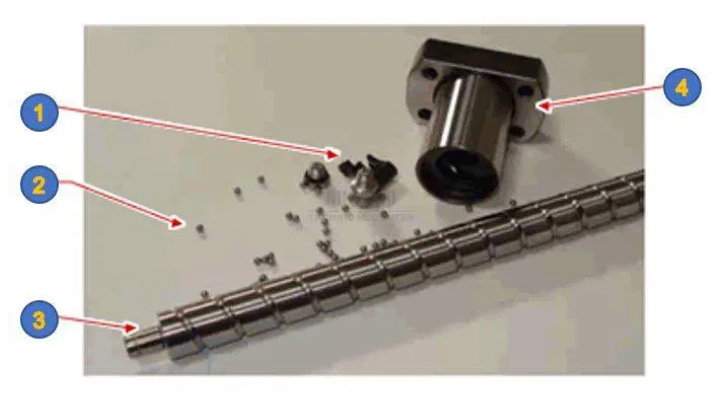

The ball screw system is a masterclass in mechanical synergy. It consists of four primary elements:

| Component | Analogous Component in a Linear Guide | Primary Function |

|---|---|---|

| 1. Return Mechanism (Pipe, Flopover, etc.) | N/A | Guides the balls back to the starting point after they exit the load-bearing grooves, ensuring continuous circulation. |

| 2. Ball Bearings | Ball Bearings | The rolling medium that minimizes friction and transfers load efficiently. |

| 3. Screw Shaft | Rail | Provides the fixed path and rotary input that determines the direction of the nut's movement. |

| 4. Nut | Slide Block | Executes the linear motion by enclosing the ball bearings and engaging the screw shaft grooves. |

Additional components like the Ball Groove (the path for the bearings) and Seals (to keep foreign objects out and grease in) are essential for maintaining precision and longevity.

The Mechanics of Motion: Ball Bearing Flow Patterns

The linear movement capability of a ball screw is heavily dependent on how the ball bearings are channelled back to the start of the thread. This is known as the ball bearing flow pattern. Here are four common circulation types:

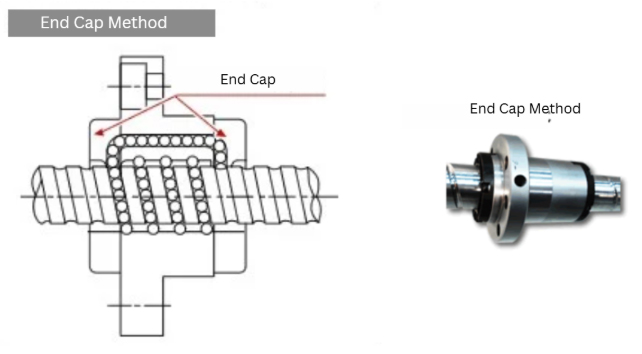

End Cap Type:

Mechanism: Balls circulate via specific ball flow holes built into the nut's inner wall and return via end caps fitted at both ends of the nut.

Application: Excellent for high-speed drive applications.

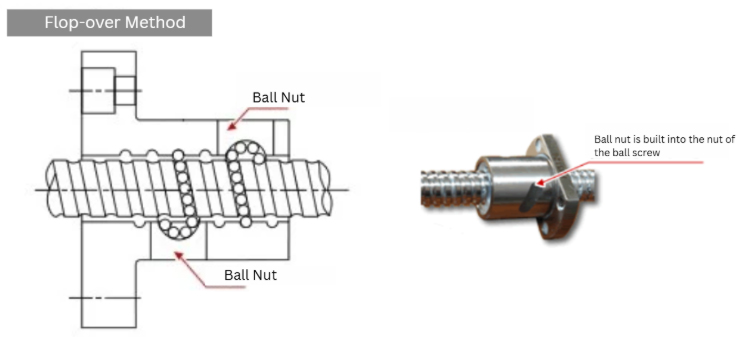

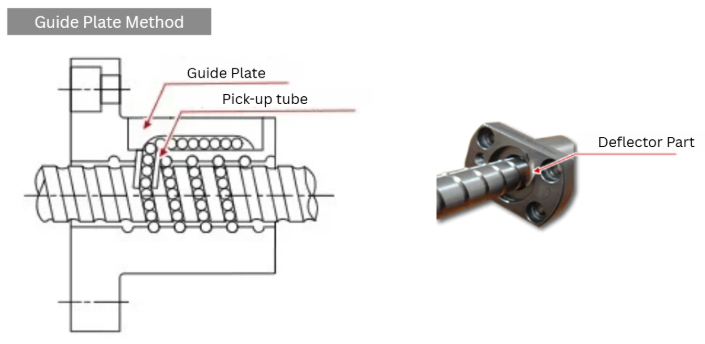

Flopover (Deflector) Type:

Mechanism: A small roller assembly (deflector) is embedded inside the nut. After completing one revolution of the screw thread, the deflector reverses the ball's direction, forcing it back into the start of the next groove.

Application: Ideal for achieving miniaturization and a compact structure.

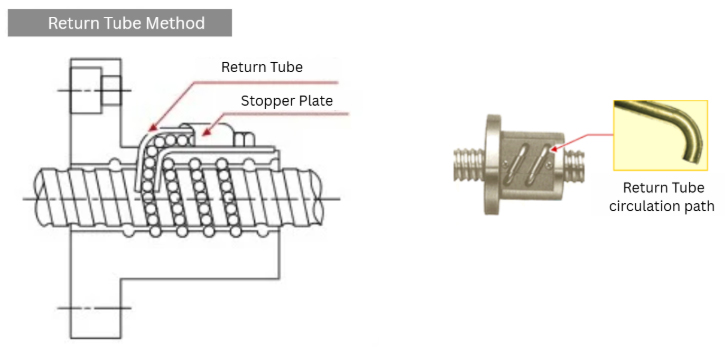

Return Tube Type:

Mechanism: A simple external tube is mounted onto the outside of the nut to collect and guide the balls back to the beginning of the thread.

Application: Simple and suitable for mass production, but the external tube makes the overall nut assembly larger.

Guide Plate Type:

Mechanism: Uses a guide plate instead of an external tube or internal deflector to circulate the ball bearings.

Application: Suitable for designs requiring a reduced structural size.

Accuracy is Everything: The Critical Role of the Screw Shaft

While the nut and bearings manage circulation, the screw shaft dictates the ultimate precision of the system. The shaft's accuracy depends entirely on its manufacturing method. Understanding the difference between these two types is vital for any design choice:

| Feature | Rolled Ball Screw | Precision (Ground) Ball Screw |

|---|---|---|

| Shape |  |

|

| Manufacturing | Formed by rolling the shaft through a mold. | Formed by grinding the grooves with a high-precision CNC machine. |

| Accuracy Grade | Lower grades (C10, C7) | Higher grades (C5, C3, C2, C0) |

| Price Point | Inexpensive and cost-effective. | Significantly higher price point. |

| Typical Use | General automation, simple positioning (e.g., small 3D printers). | High-precision industrial applications (e.g., large CNC machining, measurement equipment). |

Decoding Accuracy Grades (C0 to C10)

The accuracy grade of a ball screw is denoted by a letter and a number (e.g., C5, C3). The letter 'C' signifies the JIS Standard Class for commercial-use ball screws.

The rule is simple: The lower the number, the higher the accuracy.

A C10 screw has the lowest positional accuracy tolerance, while a C0 screw has the highest. For high-demand applications requiring sub-micron movement consistency, a C3 or C2 grade (Precision Ball Screw) is mandatory.

Optimize Your Motion System

Understanding the relationship between the screw shaft, the nut's internal flow pattern, and the accuracy grade is the key to selecting a ball screw that delivers maximum performance and longevity for your specific machine design.

Are you ready to elevate your linear motion precision? You can explore and purchase a wide range of ball screws engineered for every application right at Misumi.