(!)NOTE : Windows 7 users won’t be able to use some latest features of eCatalog/WOS since Microsoft is ending support for Windows 7 on 14 Jan, 2020. Please upgrade your system for uninterrupted services.

- Due to an increase in demand, the lead time of some of the electrical items from our eCatalogue has increased abnormally and may cause delays in delivery or order suspension. We apologize for the inconvenience and appreciate your kind understanding. Once the supply will get normalized, we will update the same.

Specification/Dimensions

-

Nominal of Thread D(Ø)

-

Pitch(mm)

-

Material

- S45C

- SUS303

-

Shaft Overall Length L(mm)

-

Type

- Standard

- With keyway type

-

C(mm)

-

J(mm)

-

Q(mm)

-

S(mm)

Days to Ship

-

- All

- 13 Day(s) or Less

Specify Alterations

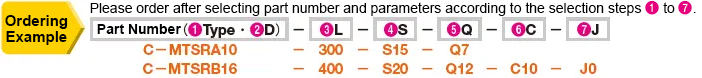

Lead Screws-One End Stepped Type

Copy Part Number URL to Clipboard

The part number URL has been copied into your clipboard.-

- Order Qty :

-

-

- Price :

- ---

-

- Total Price :

- ---

-

- Days to ship :

- ---

Select part number to Order Now/ Add to Cart

- CAD Data unavailable

Product Description

- Lead Screws-One End Stepped Type

- C-MTSRA, C-MTSTRA, C-MTSRB and C-MTSTRB are in MISUMI economy series.

- C-MTSRA and C-MTSTRA are Screw Turn Direction: Right-hand thread

- C-MTSRB and C-MTSTRB are Screw Turn Direction: Right-Hand Thread with Keyway

- Material of C-MTSRA and C-MTSRB: Equivalent to S45C

- Material of C-MTSTRA and C-MTSTRB: Equivalent to SUS303

- Thread Nominal Dia.: 8, 10, 12, 14, 16, 20, 22 and 25 mm.

- Shaft Overall Length L: 50-1200 mm.

- Thead pitch: 1.5, 2, 3 ,4 and 5

Economy series lead screw with high quality rolled rollers made of material SUS303 or S45C ensures 7e precision. 7 types of additional processing are available at both ends, basically meeting all shapes, no need for secondary processing after purchase.

Used with Economy series lead screw nuts, it ensures consistent thread clearance.

| Standard | With Keyway Type |  Material Material |  Surface Treatment Surface Treatment | ||

| Right-Hand | Left-Hand | Right-Hand | Left-Hand | ||

| C-MTSRA | C-MTSLA | C-MTSRB | C-MTSLB | S45C equivalent | - |

| C-MTSBRA | C-MTSBLA | C-MTSBRB | C-MTSBLB | S45C equivalent | Ferroferric Oxide Protective Film |

| C-MTSTRA | C-MTSTLA | C-MTSTRB | C-MTSTLB | SUS303 equivalent | - |

Type Type |  Thread Nominal D Thread Nominal D | 1mm increments |  Q Selection Q Selection | 1mm increments | Thread Pitch P | |||||||

| Right-Hand | Left-Hand |  L L |  S S |  C C |  J J | |||||||

| Standard C-MTSRA C-MTSBRA C-MTSTRA With Keyway Type C-MTSRB C-MTSBRB C-MTSTRB | Standard C-MTSLA C-MTSBLA C-MTSTLA With Keyway Type C-MTSLB C-MTSBLB C-MTSTLB | (8) | 50~ 500 | When Q≤9 D2≤S≤Q×5 When Q≥10 2≤S≤Q×7 | 6 | C≤60 S-C-J≥2 | J≥2 or J=0  When J=0,keyway R will be eliminated on the shaft end side When J=0,keyway R will be eliminated on the shaft end side | 1.5 | ||||

| (10) | 80~1000 | 6 | 7 | 2 | ||||||||

| 12 | (6) | 7 | 8 | 9 | ||||||||

| 14 | 8 | 9 | 10 | 3 | ||||||||

| 16 | 100~1200 | 9 | 10 | 12 | ||||||||

| 20 | 150~1200 | 10 | 12 | 14 | 15 | 4 | ||||||

| 22 | 10 | 12 | 14 | 15 | 5 | |||||||

| 25 | 12 | 14 | 15 | 16 | 17 | |||||||

Dimensions in ( ) are not applicable to Right-Hand Thread with Keyway.

Dimensions in ( ) are not applicable to Right-Hand Thread with Keyway. When combined with economy series position indicators, Q8~14 are standard dimensions.

When combined with economy series position indicators, Q8~14 are standard dimensions.

Continuous metal tissue fibers guarantee high thread strength.

Cold hardening ensures more wear-resistant thread surface.

* Economy series position indicator has not been launched yet. Coming soon.

Standardize the special "support unit" for lead screw.

There is no need to design the bearing mechanism.

·Standardize the shape of lead screw shaft end

If the shaft diameter and length are determined, they can be combined directly with the support unit.

There is no need for complicated shaft end shape design.

·No need for combination design of various parts

If the specifications of each part are met, it can be assembled directly.

There is no need for complicated combination design of various parts.

2. When contacting the product, please use protective gloves, safety shoes and other protective equipment to ensure safety.

| Part Number |

|---|

| C-MTSRA8-[50-500/1]-S[2-30/1]-Q6 |

| C-MTSRA10-[80-1000/1]-S[2-49/1]-Q[6,7] |

| C-MTSRA12-[80-1000/1]-S[2-63/1]-Q[6,7,8,9] |

| C-MTSRA14-[80-1000/1]-S[2-70/1]-Q[8,9,10] |

| C-MTSRA16-[100-1200/1]-S[2-84/1]-Q[9,10,12] |

| C-MTSRA20-[150-1200/1]-S[2-105/1]-Q[10,12,14,15] |

| C-MTSRA22-[150-1200/1]-S[2-105/1]-Q[10,12,14,15] |

| C-MTSRA25-[150-1200/1]-S[2-119/1]-Q[12,14,15,16,17] |

| C-MTSRB12-[80-1000/1]-S[2-63/1]-Q[7,8,9]-C[3-60/1]-J[0-61/1] |

| C-MTSRB14-[80-1000/1]-S[2-70/1]-Q[8,9,10]-C[4-60/1]-J[0-68/1] |

| C-MTSRB16-[100-1200/1]-S[2-84/1]-Q[9,10,12]-C[4-60/1]-J[0-82/1] |

| C-MTSRB20-[150-1200/1]-S[2-105/1]-Q[10,12,14,15]-C[4-60/1]-J[0-103/1] |

| C-MTSRB22-[150-1200/1]-S[2-105/1]-Q[10,12,14,15]-C[4-60/1]-J[0-103/1] |

| C-MTSRB25-[150-1200/1]-S[2-119/1]-Q[12,14,15,16,17]-C[5-60/1]-J[0-117/1] |

| C-MTSTRA8-[50-500/1]-S[2-30/1]-Q6 |

| C-MTSTRA10-[80-1000/1]-S[2-49/1]-Q[6,7] |

| C-MTSTRA12-[80-1000/1]-S[2-63/1]-Q[6,7,8,9] |

| C-MTSTRA14-[80-1000/1]-S[2-70/1]-Q[8,9,10] |

| C-MTSTRA16-[100-1200/1]-S[2-84/1]-Q[9,10,12] |

| C-MTSTRA20-[150-1200/1]-S[2-105/1]-Q[10,12,14,15] |

| C-MTSTRA22-[150-1200/1]-S[2-105/1]-Q[10,12,14,15] |

| C-MTSTRA25-[150-1200/1]-S[2-119/1]-Q[12,14,15,16,17] |

| C-MTSTRB12-[80-1000/1]-S[2-63/1]-Q[7,8,9]-C[3-60/1]-J[0-61/1] |

| C-MTSTRB14-[80-1000/1]-S[2-70/1]-Q[8,9,10]-C[4-60/1]-J[0-68/1] |

| C-MTSTRB16-[100-1200/1]-S[2-84/1]-Q[9,10,12]-C[4-60/1]-J[0-82/1] |

| C-MTSTRB20-[150-1200/1]-S[2-105/1]-Q[10,12,14,15]-C[4-60/1]-J[0-103/1] |

| C-MTSTRB22-[150-1200/1]-S[2-105/1]-Q[10,12,14,15]-C[4-60/1]-J[0-103/1] |

| C-MTSTRB25-[150-1200/1]-S[2-119/1]-Q[12,14,15,16,17]-C[5-60/1]-J[0-117/1] |

| Part Number | Price | Minimum Order Qty. | Volume Discount | Days to Ship | Nominal of Thread D (Ø) | Pitch (mm) | Material | Shaft Overall Length L (mm) | Type | C (mm) | J (mm) | Q (mm) | S (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

- | 1 Piece(s) | 13 Day(s) | 8 | 1.5 | S45C | 50 ~ 500 | Standard | - | - | 6 | 2 ~ 30 | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 2 | S45C | 80 ~ 1000 | Standard | - | - | 6 ~ 7 | 2 ~ 49 | ||

- | 1 Piece(s) | 13 Day(s) | 12 | 2 | S45C | 80 ~ 1000 | Standard | - | - | 6 ~ 9 | 2 ~ 63 | ||

- | 1 Piece(s) | 13 Day(s) | 14 | 3 | S45C | 80 ~ 1000 | Standard | - | - | 8 ~ 10 | 2 ~ 70 | ||

- | 1 Piece(s) | 13 Day(s) | 16 | 3 | S45C | 100 ~ 1200 | Standard | - | - | 9 ~ 12 | 2 ~ 84 | ||

- | 1 Piece(s) | 13 Day(s) | 20 | 4 | S45C | 150 ~ 1200 | Standard | - | - | 10 ~ 15 | 2 ~ 105 | ||

- | 1 Piece(s) | 13 Day(s) | 22 | 5 | S45C | 150 ~ 1200 | Standard | - | - | 10 ~ 15 | 2 ~ 105 | ||

- | 1 Piece(s) | 13 Day(s) | 25 | 5 | S45C | 150 ~ 1200 | Standard | - | - | 12 ~ 17 | 2 ~ 119 | ||

- | 1 Piece(s) | 13 Day(s) | 12 | 2 | S45C | 80 ~ 1000 | With keyway type | 3 ~ 60 | 0 ~ 61 | 7 ~ 9 | 2 ~ 63 | ||

- | 1 Piece(s) | 13 Day(s) | 14 | 3 | S45C | 80 ~ 1000 | With keyway type | 4 ~ 60 | 0 ~ 68 | 8 ~ 10 | 2 ~ 70 | ||

- | 1 Piece(s) | 13 Day(s) | 16 | 3 | S45C | 100 ~ 1200 | With keyway type | 4 ~ 60 | 0 ~ 82 | 9 ~ 12 | 2 ~ 84 | ||

- | 1 Piece(s) | 13 Day(s) | 20 | 4 | S45C | 150 ~ 1200 | With keyway type | 4 ~ 60 | 0 ~ 103 | 10 ~ 15 | 2 ~ 105 | ||

- | 1 Piece(s) | 13 Day(s) | 22 | 5 | S45C | 150 ~ 1200 | With keyway type | 4 ~ 60 | 0 ~ 103 | 10 ~ 15 | 2 ~ 105 | ||

- | 1 Piece(s) | 13 Day(s) | 25 | 5 | S45C | 150 ~ 1200 | With keyway type | 5 ~ 60 | 0 ~ 117 | 12 ~ 17 | 2 ~ 119 | ||

- | 1 Piece(s) | 13 Day(s) | 8 | 1.5 | SUS303 | 50 ~ 500 | Standard | - | - | 6 | 2 ~ 30 | ||

- | 1 Piece(s) | 13 Day(s) | 10 | 2 | SUS303 | 80 ~ 1000 | Standard | - | - | 6 ~ 7 | 2 ~ 49 | ||

- | 1 Piece(s) | 13 Day(s) | 12 | 2 | SUS303 | 80 ~ 1000 | Standard | - | - | 6 ~ 9 | 2 ~ 63 | ||

- | 1 Piece(s) | 13 Day(s) | 14 | 3 | SUS303 | 80 ~ 1000 | Standard | - | - | 8 ~ 10 | 2 ~ 70 | ||

- | 1 Piece(s) | 13 Day(s) | 16 | 3 | SUS303 | 100 ~ 1200 | Standard | - | - | 9 ~ 12 | 2 ~ 84 | ||

- | 1 Piece(s) | 13 Day(s) | 20 | 4 | SUS303 | 150 ~ 1200 | Standard | - | - | 10 ~ 15 | 2 ~ 105 | ||

- | 1 Piece(s) | 13 Day(s) | 22 | 5 | SUS303 | 150 ~ 1200 | Standard | - | - | 10 ~ 15 | 2 ~ 105 | ||

- | 1 Piece(s) | 13 Day(s) | 25 | 5 | SUS303 | 150 ~ 1200 | Standard | - | - | 12 ~ 17 | 2 ~ 119 | ||

- | 1 Piece(s) | 13 Day(s) | 12 | 2 | SUS303 | 80 ~ 1000 | With keyway type | 3 ~ 60 | 0 ~ 61 | 7 ~ 9 | 2 ~ 63 | ||

- | 1 Piece(s) | 13 Day(s) | 14 | 3 | SUS303 | 80 ~ 1000 | With keyway type | 4 ~ 60 | 0 ~ 68 | 8 ~ 10 | 2 ~ 70 | ||

- | 1 Piece(s) | 13 Day(s) | 16 | 3 | SUS303 | 100 ~ 1200 | With keyway type | 4 ~ 60 | 0 ~ 82 | 9 ~ 12 | 2 ~ 84 | ||

- | 1 Piece(s) | 13 Day(s) | 20 | 4 | SUS303 | 150 ~ 1200 | With keyway type | 4 ~ 60 | 0 ~ 103 | 10 ~ 15 | 2 ~ 105 | ||

- | 1 Piece(s) | 13 Day(s) | 22 | 5 | SUS303 | 150 ~ 1200 | With keyway type | 4 ~ 60 | 0 ~ 103 | 10 ~ 15 | 2 ~ 105 | ||

- | 1 Piece(s) | 13 Day(s) | 25 | 5 | SUS303 | 150 ~ 1200 | With keyway type | 5 ~ 60 | 0 ~ 117 | 12 ~ 17 | 2 ~ 119 |

Loading...

Basic Information

| Shaft Shape | One End Stepped Type | Screw Turn Direction | Right-hand thread | Surface Treatment | Not Provided |

|---|---|---|---|---|---|

| Type | Lead Screw Shafts | Shaft Type | Rolled |

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Frequently asked question (FAQ)

- Question: What is the difference between a trapezoidal screw and a ball screw?

-

Answer:

The ball screw uses rolling friction, while the trapezoidal screw uses sliding friction.

The ball screw is not self-locking, while the trapezoidal screw is self-locking to a certain extent. - Question: Can it be used in conjunction with other trapezoidal screws?

- Answer: Due to the slight differences between JIS standard and national standard, it is not recommended to mix economy series trapezoidal screws with existing products of MISUMI or other brands.

How can we improve?

How can we improve?

Thank you for your time.

Your feedback is essential for our continuous improvement

Privacy Policy

Thank you for your cooperation.

Thank you for your time.

Your feedback is essential for our continuous improvement

Please use the inquiry form.

Privacy Policy